Pump Solutions Group Neptune Series 560 dia-PUMP User Manual

Page 13

9

SECTION III

NORMAL MAINTENANCE

9.0

MAINTENANCE

Under normal conditions, the “dia-Pump”does not require any significant amount of maintenance. It is advised

that periodic visual observations be made of the oil level to make sure that it is within limit (see fig 1, page#5).

The liquid end of the pump should also be inspected for leakage. These observations should be made regularly,

at least every 48 hours.

The hydraulic fluid should be drained and replaced TWICE a year, using the drain plug (FIG #510, page#18) on

the side of the pump. This change can be scheduled with the normal factory maintenance at seasonal periods.

10.0

CHECK VALVES: REMOVING, CLEANING, AND REPLACING

The “dia-Pump” incorporates a unique check valve design whereas the discharge and suction piping NEED

NOT be disturbed in order to service the valves. Should the valves need cleaning, remove as follows:

NOTE: For PVC or KYNAR heads, the connection piping have to be removed.

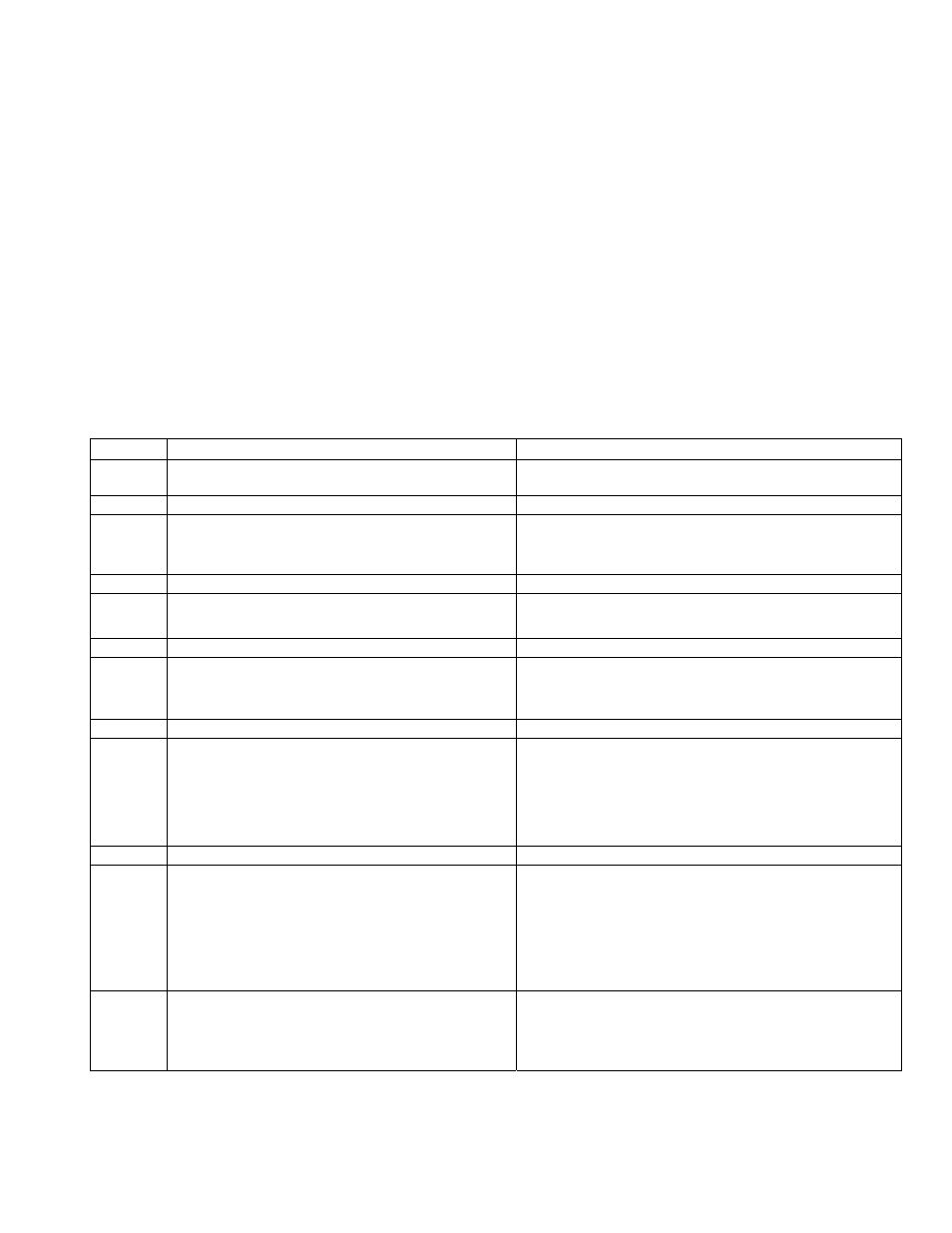

For Metal Heads

For plastic heads

(Refer to drawings on page#18 for referenced

FIG numbers)

(Refer to drawings on page#20 for referenced FIG

numbers)

10.0.1

Disconnect the power source from the drive motor.

Remove vent plug (FIG#5604) with anti-siphon

spring (FIG#5666) if installed.

10.0.2

Remove discharge cap (FIG#5610).

Relieve all pressure from the piping system and close

the inlet and outlet shutoff valves.

10.0.3

Loosen and remove suction and discharge valve

cartridge

Remove suction cap (FIG#5612).

(FIG#2) slowly to drain away any trapped liquid.

10.0.4

With heavy wood dowel or bar of soft material,

tap and push complete valve stack out of pump

from top through to bottom.

Clean valve cartridge with suitable solvent. Both valve

cartridge are complete and integral unit and should

not be disassembled for cleaning. If the valves are

found to be worn in and need of replacement, an

entire valve cartridge in either suction or discharge

should be ordered.

The valve stack consists of:

4 Valve Balls (FIG#2340)

4 Valve Seats (FIG#5695)

1 Stack Spacer (FIG#5693)

3 Ball Guides (FIG#5691)

4 Valve Seat O-rings (FIG#2342)

To replace, reverse above procedures. Make sure that

all arrows on the valve body point upwards.

10.0.5

Clean valve stack parts with a suitable solvent.

Replace in same order as removed from top to

bottom, putting suction valve cap (FIG#5612) in

place with O-ring first.

CAUTION: Do not over tighten PVC Suction and discharge valves, as the PVC material is not able to withstand

excessive force and can fail. Teflon paste is an excellent thread lubricant and may be applied.