Iii. safety precautions and operating guidelines, Iv. handling and storage, Lifting and moving – Spencer Power Mizer Multistage Centrifugal Cast Blowers User Manual

Page 4

4

III. Safety Precautions and

Operating Guidelines

• Read and follow all instructions in this manual. If you have

any questions, consult your Spencer Representative.

• Use appropriately rated lifting equipment for installation,

removal, or disassembly of heavy components.

• Remove inlet and discharge covers, silica gel bags and

crating materials prior to blower installation.

• Inspect all openings for tools and foreign matter before

connecting accessories or piping.

• Perform all installing and operating procedures with care,

following sound practices to avoid accidents and damage.

• Avoid climbing on or over the blower; use proper staging

and ladders for exterior machine access.

• Be sure isolation pads are correctly located beneath the

blower base. See page 5.

• Confirm that the blower is level so that oil level readings will

be accurate.

• Install flexible connectors on inlet and discharge flanges to

isolate piping loads from the blower.

• Ensure that piping, machine guards and accessories such

as filters or valves are properly installed and fastened.

• Fill oilers of oil-lubricated blower bearings with recommended

type of fresh oil as instructed on page 7.

• Install a filter on the inlet when the blower is used in pressure

service and keep it clean.

• Allow only qualified electricians to work on electrical equip-

ment.

• Lock electrical circuits open and tag them during servicing

of equipment.

• Align the coupling as instructed on page 6.

• Remove alignment tools and replace coupling guard before

restarting blower.

• Turn the blower shaft by hand to verify free rotation without

rubbing or noise.

• Check motor rotation as instructed on page 7.

• Do not operate the blower where there is an ambient tem-

perature above 104 °F (40 °C), unless it has been designed

for such conditions.

• Operate blower with sufficient restriction at all times (via

connected piping system or throttled butterfly valve) to

avoid motor overloading.

• Do not allow blower operation in surge (unstable low flow)

or damage may result.

• Rotate shaft of stored or inactive blowers a few times by

hand every week.

• Use only genuine Spencer parts for repairs and service.

IV. Handling and Storage

Each Spencer blower is carefully balanced and tested at the

factory. For optimum performance, it must be handled with

care during unloading and installation.

Check the shipment for damage upon arrival; file any claims

with the shipper and notify Spencer.

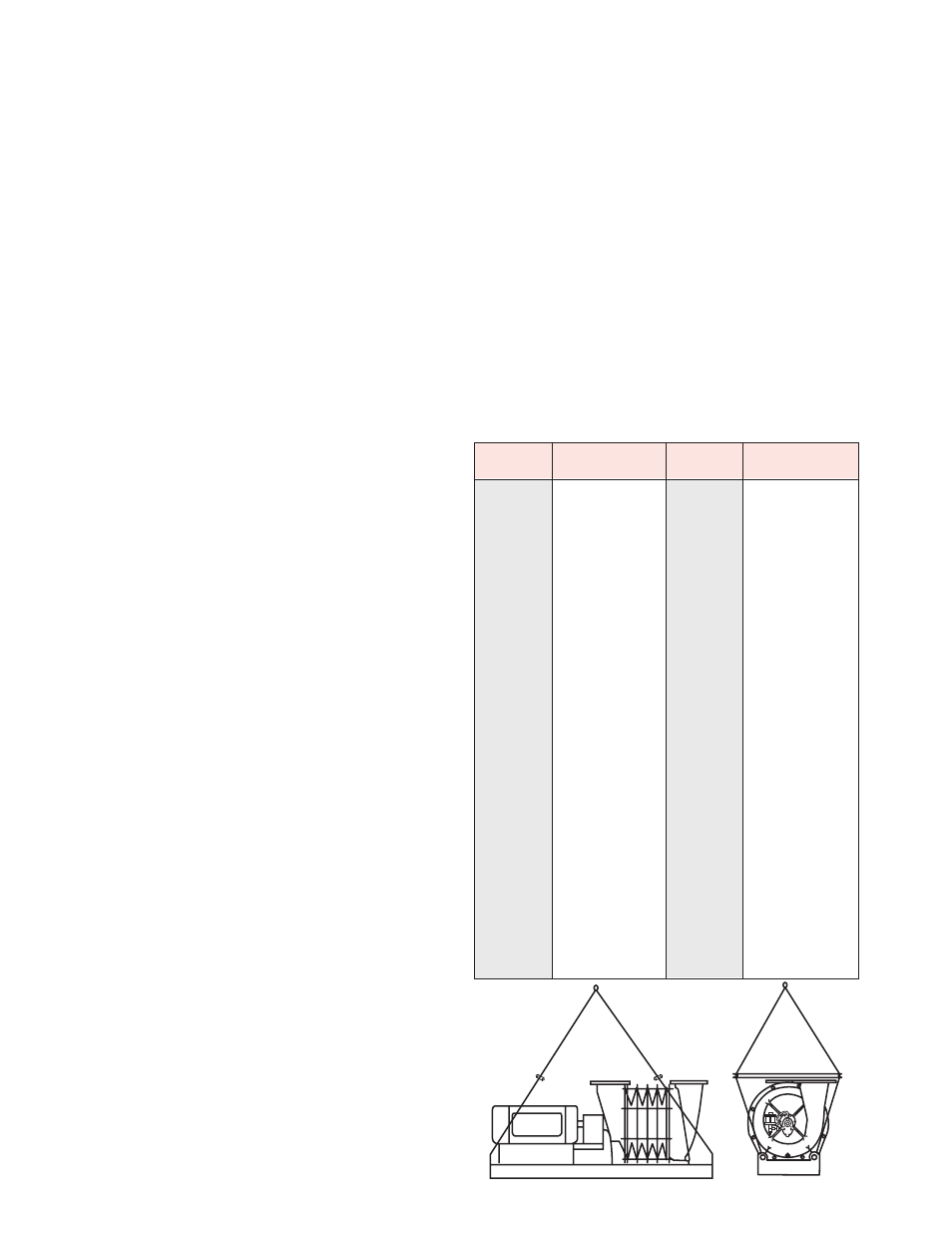

Lifting and Moving

Moving of this equipment is the customer’s responsibility and

should be performed or directed by experienced riggers using

accepted rigging practices and safety precautions. The blower/

motor assembly can be lifted and relocated with an overhead

crane or hoist. Always use lifting equipment rated for the loads

involved–see accompanying table of approximate machine

weights.

CAuTIOn: use of alternative lifting methods such as a

forklift is not recommended, due to risk of equipment

damage or misalignment.

Approximate Machine Weights

(blower and base without motor)

C44

3487

1584

C45

4115

1868

C46

4544

2063

C47

4997

2269

C48

5425

2463

C52

3852

1747

C53

4518

2049

C54

5344

2424

C55

6010

2726

C56

6676

3028

C57

7542

3421

C58

8208

3723

C62

4914

2231

C63

6064

2753

C64

6989

3173

C65

8049

3654

C66

8926

4052

C72

10150

4604

C73

12100

5489

C74

14600

6623

C75

17200

7804

C76

20300

9207

C81

14500

6577

C82

18000

8165

C83

21500

9752

C84

25000 11340

C85

28500 12927

C86

32000 14515

Weight

Weight

Model No.

lb

kg

Model No.

lb

kg

C13

177

80

C14

188

85

C15

200

91

CS22 1047 475

CS23 1224 555

CS24 1404 637

CS25 1625 737

CS26 1805 819

CS27 1986 901

CS28

2217 1006

CS29

2395 1086

CS210 2576 1169

C32

1917

870

C33

2225

1009

C34

2596

1178

C35

2928

1328

C36

3285

1490

C37

3688

1673

C38

4004

1816

CS32 1980 898

CS33

2319 1052

CS34

2823 1281

CS35

3162 1434

CS36

3501 1588

CS37

4019 1823

CS38

4358 1977

CS39

4697 2131

C42

2630

1194

C43

3058

1389