Labyrinth seal removal and replacement – Spencer Power Mizer Multistage Centrifugal Cast Blowers User Manual

Page 12

12

NOTE: No shaft support is needed; the shaft will be supported

by the labyrinth seals.

Bearing Replacement Procedure

CAuTIOn: Maintain extreme cleanliness to avoid bearing

contamination and damage. use new gaskets.

1. Install components in the reverse order of disassembly.

2. Press the bearing onto the shaft until seated against the

shoulder. Pusher kits are available from Spencer.

NOTE: If present, oil slinger ‘dimples’ should face the

bearing.

3. Lubricate according to instructions on pages 8 and 9.

Series 3000, 4000, 5000, 6000

Bearing Removal Procedure

1. Remove coupling guard.

2. Split the coupling halves, recording the relative position of

the motor and blower shafts (not the coupling shells).

3. Unbolt and move motor.

4. Use puller to remove blower coupling half. Apply heat if

necessary.

5. For oil-lubricated bearing, drain all oil by removing drain

plug from the bottom of the bearing sump.

6. For oil-lubricated bearing, disconnect oiler tubing and oiler

if necessary.

7. Remove bearing cap.

8. Remove shaft locknut and lockwasher.

9. Remove bearing housing bolts.

10. Using a two-arm puller and the two tapped puller holes

(5/8") in the bearing housing, remove housing, bearing(s)

and bronze seal, if present, as a unit.

11. ‘Drift’ the bearing(s) out of the housing.

NOTE: No shaft support is needed; the shaft will be sup-

ported by the labyrinth seals.

Bearing Replacement Procedure

CAuTIOn: Maintain extreme cleanliness to avoid bearing

contamination and damage. use new gaskets.

1. Install components in the reverse order of disassembly.

NOTE: If the assembly is equipped with a bronze rotation

shaft seal, start the seal on the shaft, but do not seat.

2. Press the bearing(s) onto the shaft until seated against

the shoulder. Pusher kits are available from Spencer.

NOTE: Double bearings must be installed back-to-back.

3. Lubricate according to instructions on page 9.

Series 7000, 8000

Bearing Removal Procedure

1. Remove coupling guard.

2. Split the coupling halves, recording the relative position of

the motor and blower shafts (not the coupling shells).

3. Unbolt and move motor.

4. Use puller to remove blower coupling half. Apply heat if

necessary.

5. Drain all oil by removing drain plug from the bottom of the

bearing sump.

6. Remove bearing cap.

7. Remove slinger cover, shaft locknut,

lockwasher, spacer, oil slinger, and

bearing retainer.

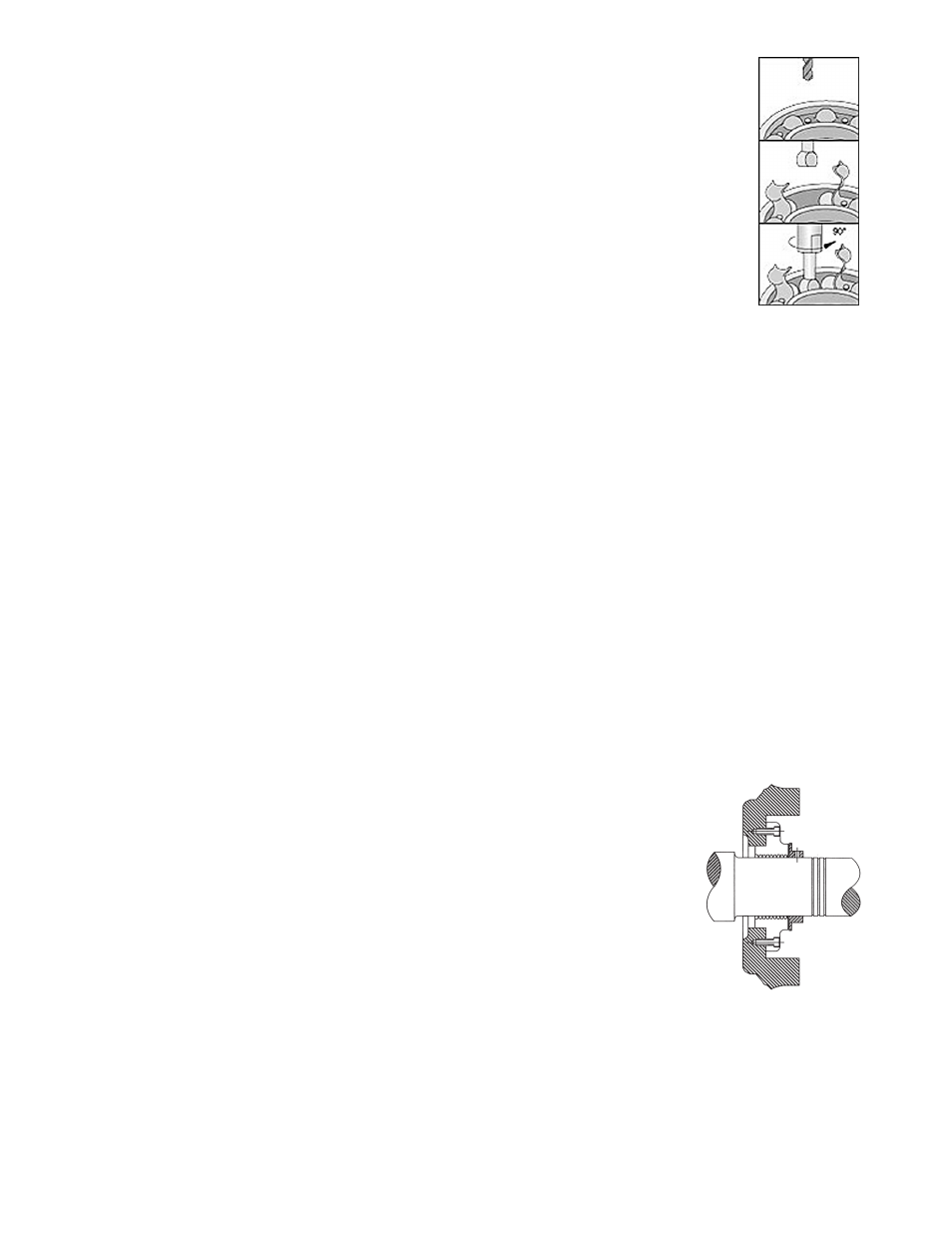

8. Open a section of the ball cage on the

bearing and cut the swarf out.

9. Using a blind housing puller kit (avail-

able from Spencer), insert the appro-

priate bearing adapter and rotate it

90 degrees to achieve a positive grip

within the bearing race.

10. Prepare the opposite cage area in the

same manner and insert the second

adapter.

11. Connect both adapters to the main rod.

Assemble beam and spindle.

12. Pull out bearing.

NOTE: No shaft support is needed; the shaft will be supported

by the labyrinth seals.

Bearing Replacement Procedure

CAuTIOn: Maintain extreme cleanliness to avoid bearing

contamination and damage. use new gaskets.

1. Install components in the reverse order of disassembly.

2. Heat the bearing. Normally a bearing temperature of 80 to

90 °C (144 to 162 °F) above that of the shaft is sufficient for

mounting.

CAuTIOn: never heat a bearing to a temperature

greater than 125 °C (257 °F), never heat a bearing

using an open flame.

3. Press the bearing onto the shaft until seated against the

shoulder. Pusher kits are available from Spencer.

NOTE: Oil slinger ‘dimples’ should face the bearing.

4. Lubricate according to instructions on page 7.

Labyrinth Seal Removal and

Replacement

NOTE: Labyrinth seals are non-contacting and do not wear,

but if a seal is damaged during bearing replacement, leakage

will increase and the seal should be replaced.

1. Remove the bearing housing,

following the appropriate bear-

ing removal instructions in this

manual.

2. Remove the heat fan if pres-

ent. Disk-type heat fans are

secured by two setscrews;

bladed heat fans are clamped

to the shaft.

3. Support the shaft and slide the

seal clear. Gently lower the

shaft.

4. Slide the new seal onto the

shaft, raise and recenter the

shaft, then seat the seal and

fasten securely.

CAuTIOn: use care; the seal material is soft and

easily damaged.

5. Disk-type heat fan: Use a feeler gage to position the fan

.050" from the seal face and tighten.

Bladed heat fan: Center the fan between the seal face and

the bearing journal and tighten.

6. Replace bearing(s) following the appropriate bearing

replacement instructions in this manual.

Labyrinth Seal