John Wood Noritz N-069M-DV User Manual

Page 72

72

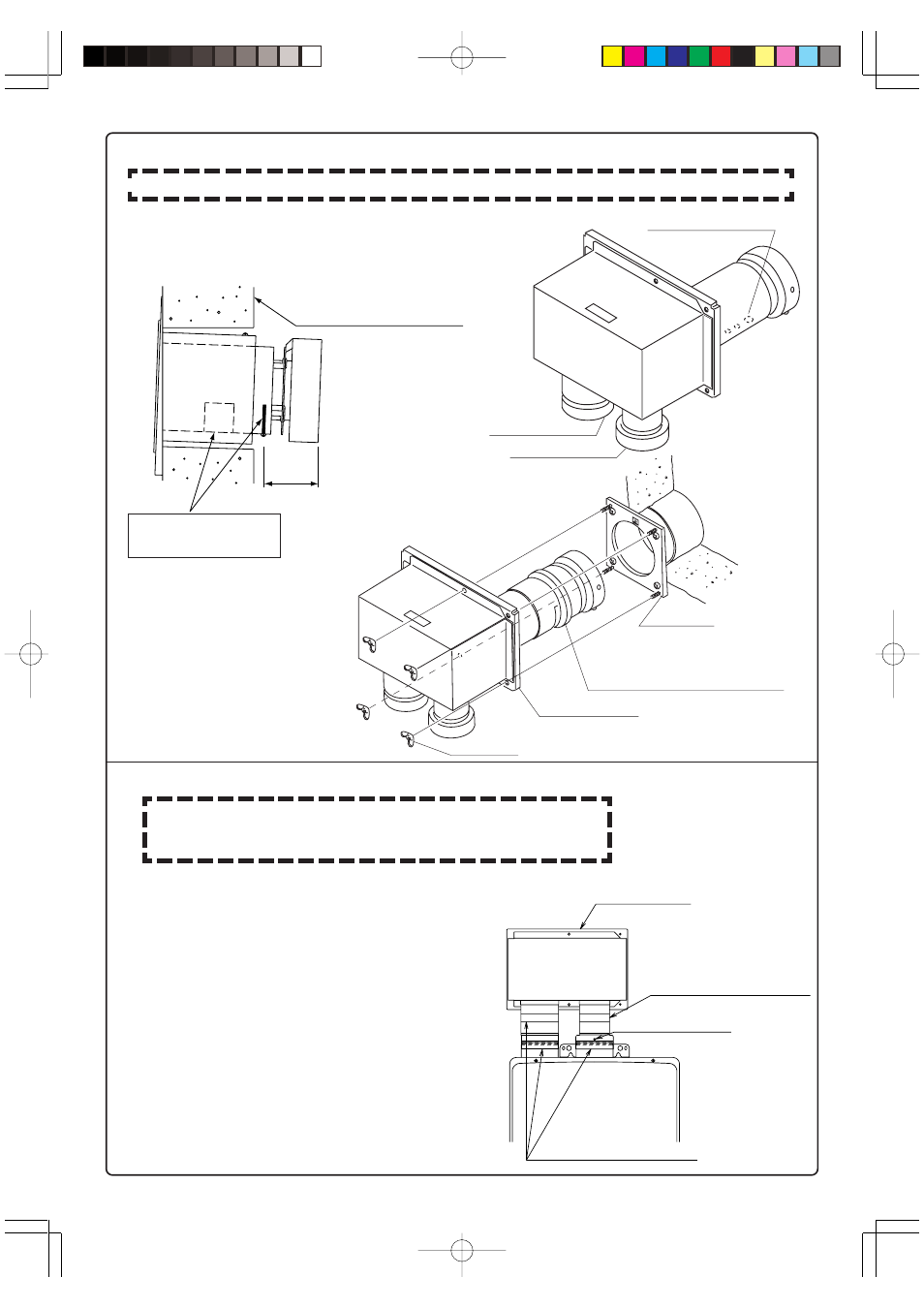

4) Adjusting the vent terminal length

Combustion and operation problems my result if the vent terminal isn't set to the appropriate length.

The length of the vent terminal must be adjusted

to fit the wall thickness before the installation

is completed.

Remove this screw and slide

out the external cylinder.

Intake slide pipe

At this point, make sure the

supply and exhaust slide pipes

have been inserted into vent

terminal.

Make sure the connections are secure and take measures to

prevent exhaust gas from leaking. Use high temperature sealant

if necessary.

(1) Drill a hole (0.2" dia.) through the water heater exhaust flue

collar to meet with the hole in the exhaust slide pipe of

the vent terminal

(2) Seal connections between the water heater and the

vent terminal with high temperature sealant to ensure

exhaust gas won't leak.

(3) Screw the exhaust slide pipe of the vent terminal to the

flue collar of the water heater using the included tapping

screw.

(4) Cover all of the connections between the water heater

and the vent terminal with the included aluminum

tape.

* Note that the aluminum tape by itself is not sufficient to

make the connection gas tight and prevent the terminal

from becoming disconnected from the water heater.

(5) After completing the installation, perform a test run of

the water heater according to the installation manual.

Sleeve

Standard projection

length: 3 inches

The red line should be visible.

The red rectangle should not be

visible from the outdoors.

External wall surface

Exhaust slide pipe

Vent terminal

Wing nut

Wind packing along the red rectangle

only for wall thicknesses of 14.5" to

27" support products.

Vent terminal

Aluminum tape (short)

Tapping screw

Aluminum tape (long)

Exhaust

pipe

Intake

pipe

5) Extend the supply and exhaust slide pipes to connect the vent terminal to the water heater.

SAR8192-2_068_073_E_J.p65

05.11.29, 9:01 PM

Page 72

Adobe PageMaker 6.5J/PPC