Warning, Temperature and pressure (t&p) relief valve – John Wood Superflue Power Vent (75 Gallon) User Manual

Page 17

DO NOT use any lead based solder in potable water lines.

Use appropriate tin-antimony or other equivalent material.

DO NOT tamper with the gas control/thermostat, igniter or

temperature and pressure relief valve. Tampering voids all

warranties. Only qualified service technicians should serv-

ice these components.

DO NOT use with piping that has been treated with chro-

mates, boiler seal, or other chemicals.

DO NOT add any chemicals to the system piping which will

contaminate the potable water supply.

Closed System/Thermal Expansion

Periodic discharge of the temperature and pressure relief

valve may be due to thermal expansion in a closed water

supply system. The water utility supply meter may contain a

check valve, backflow preventer or water pressure-reducing

valve. This will create a closed water system. During the

heating cycle of the water heater, the water expands caus-

ing pressure inside the water heater to increase. This may

cause the temperature and pressure relief valve to dis-

charge small quantities of hot water. To prevent this, it is

recommended that a diaphragm-type expansion tank (suit-

able for potable water) be installed on the cold water supply

line. The expansion tank must have a minimum capacity of

5.6 litres (1.5 US gallons) for every 190 litres (50 US gal-

lons) of stored water and be rated at the working pressure

of the water heater. Contact the local water supplier or

plumbing inspector for information on other methods to con-

trol this situation.

Important: Do not plug or remove the temperature and

pressure relief valve.

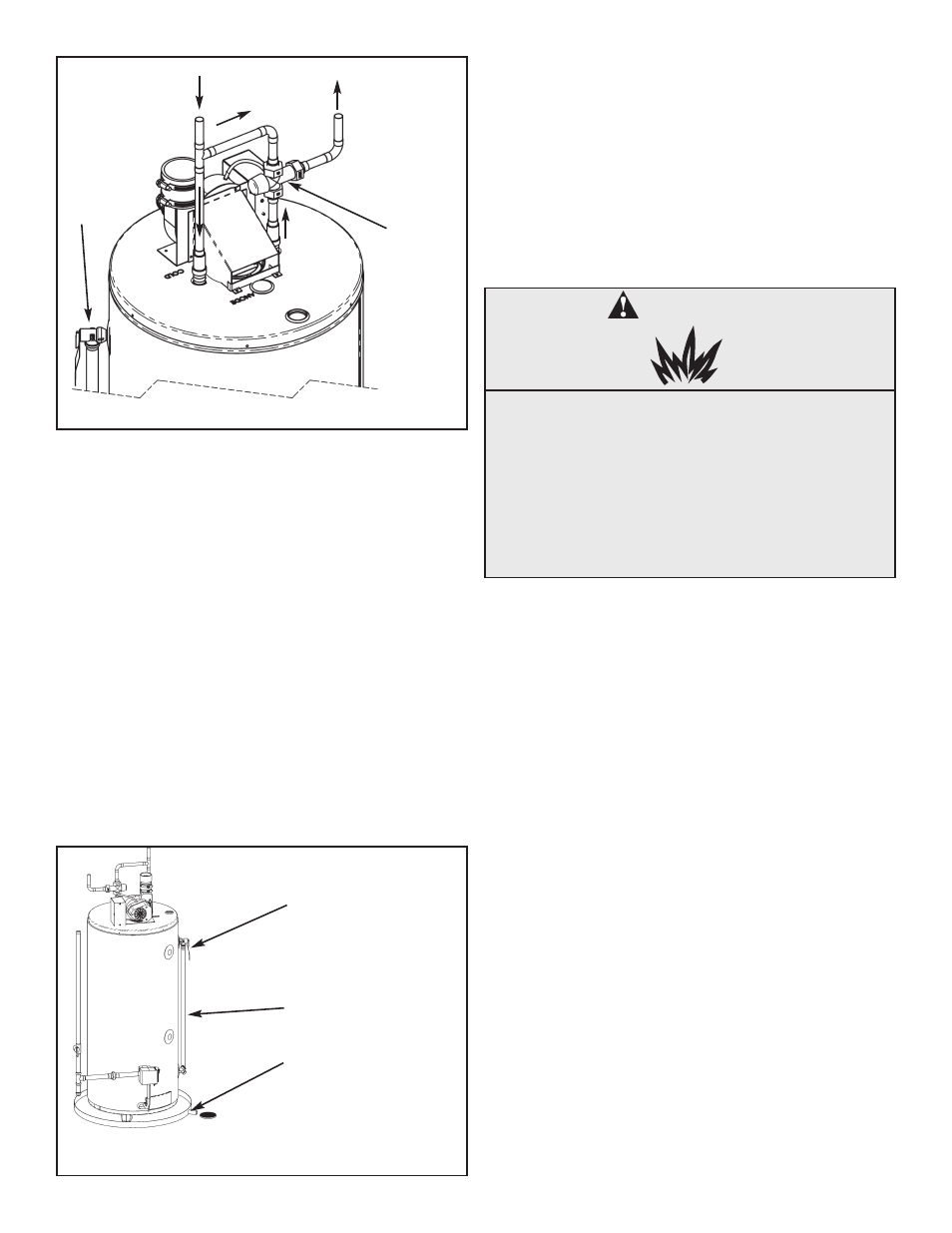

Temperature and Pressure (T&P) Relief

Valve

For protection against excessive pressures and tempera-

tures, a temperature and pressure relief valve must be

installed in the opening marked "T&P RELIEF VALVE" (see

Figure 17). This valve must be design certified by a nation-

ally recognized testing laboratory that maintains periodic

inspection of the production of listed equipment or materials

as meeting the requirements of the "Standard For Relief

Valves For Hot Water Supply Systems", ANSI

Z21.22/CSA 4.4. The function of the temperature and pres-

sure relief valve is to discharge water in large quantities in

the event of excessive temperature or pressure developing

in the water heater. The valve's relief pressure must not

exceed the working pressure of the water heater as stated

on the data plate.

Important: Only a new temperature and pressure relief

valve should be used with your water heater. Do not use an

old or existing valve, as it may be damaged or not adequate

for the working pressure of the new water heater. Do not

place any valve between the relief valve and the tank.

The Temperature and Pressure Relief Valve:

• Must not be in contact with any electrical part.

• Must be connected to an adequate discharge line.

• Must not be rated higher than the working pressure

shown on the data plate of the water heater.

The Discharge Line/Driptube:

• Must not be smaller than the pipe size of the relief valve

or have any reducing coupling installed in the discharge

line.

– 17 –

COLD

WATER

INLET

HOT

WATER

OUTLET

TEMPERING

VALVE (SET

TO 49°C

(120°F))

TEMPERED

WATER TO

FIXTURE

Figure 16 Tempering Valve Installation

FOLLOW THE

TEMPERING

VALVE MANU-

FACTURER'S

INSTRUCTIONS

T&P VALVE

AND DIS-

CHARGE

LINE

COLD W

ATER

Figure 17 Temperature & Pressure Relief Valve

Installation

TEMPERATURE AND

PRESSURE RELIEF

VALVE

DISCHARGE LINE 19mm (3/4 in.)

MIN. DO NOT CAP OR PLUG.

DRAIN PAN. CONNECT TO

PROPERLY OPERATING

FLOOR DRAIN.

WARNING

Explosion Hazard

• If the temperature and pressure relief

valve is dripping or leaking, have a

licensed plumber repair it.

• Do not plug valve.

• Do not remove valve.

• Failure to follow these instructions can

result in death or an explosion.