John Wood Superflue Power Vent (75 Gallon) User Manual

Page 13

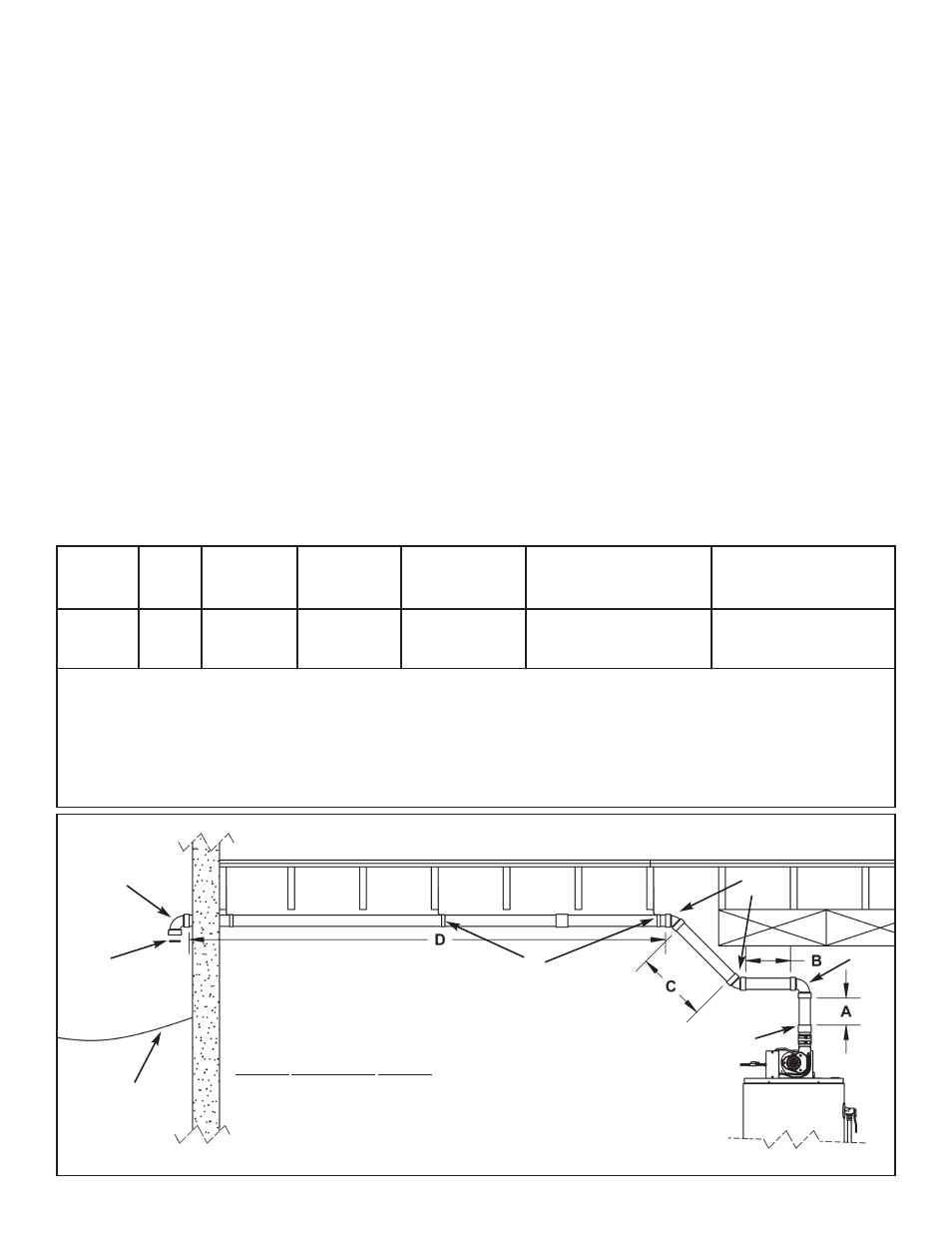

Venting terminations and sizing

• Refer to Figure 8 and Table 2 for vent pipe materials

and sizing and Figure 11 for vent termination clear-

ances. Examples of the vent terminations are shown in

Figures 9 and 10. If the installation requires a vent riser,

suitable drainage must be provided to ensure conden-

sation does not accumulate. Termination through a roof

is shown Figure 12.

• G/JW75 gallon models are supplied with a 76mm (3 in.)

termination elbow that includes a steel mesh rodent

screen and a 76mm (3 in.) plastic screen.

• The screen is required to keep foreign objects, rodents

and small birds from entering the venting system and

only one (1) screen is to be installed in the termination

elbow. These screens have been sized to ensure maxi-

mum energy efficiency of the venting system based on

the "equivalent length" of the vent piping. How to deter-

mine the equivalent length is shown in Figure 8. The

appropriate screen is to be installed into the end of the

termination elbow and secured with a small amount of

silicone sealant. This will allow for easy removal for

inspection and cleaning.

Venting instructions

1. Plan the venting layout starting at the vent termination

and work back toward the heater. Take into considera-

tion the style and position of the vent termination, the

vent pipe routing, elbows and connectors required and

the necessary support hangers.

2. G/JW75 gallon heaters use 76mm (3 in.) schedule 40

venting material. Allowable venting length is determined

using the “Equivalent vent length” method described in

Table 2. See also section on “Vent pipe connection to

blower”.

3. Venting should be as direct as possible with the fewest

number of fittings. Use long radius 45-degree and long

radius 90-degree elbows wherever possible.

4. Do not use 90-degree elbows "back to back" and do not

use street elbows. Maintain a minimum 150mm (6 in.)

straight section between elbows. Closely coupled and

short radius elbows reduce the venting capacity. Figure

6 shows examples of vent pipe connections.

5. DO NOT USE AN ELBOW AS A SUPPORT POINT.

Elbows are not designed to carry the weight of the vent-

ing system.

– 13 –

Example for calculating equivalent feet.

Section “A” . . . . . . 0.15m . . (0.5 ft.)

90° elbow . . . . . . . 2.44m . . (8.0 ft.)

Section B . . . . . . . 0.31m . . (1.0 ft.)

45° elbow . . . . . . . 1.22m . . (4.0 ft.)

Section C . . . . . . . 0.46m . . (1.5 ft.)

45° elbow . . . . . . . 1.22m . . (4.0 ft.)

Section D . . . . . . . 4.57m . (15.0 ft.)

Total Equivalent . 10.37m . (34.0 ft.)

Based on this example use the (fully open) rodent

screen for vent length greater than 6.1 equivalent

metres (20 equivalent ft.) (see Figure 7).

NOTE: VENT PIPE MUST BE SUPPORTED EVERY 1.2m (4 ft.). TO PREVENT VIBRATION, USE ISOLATION

PADS WHEN ATTACHING STRAPS TO FLOOR JOISTS, WALLS OR CEILINGS.

PVC ADAPTER

(SUPPLIED)

STRAP

150mm

(6 in.)

MIN.

45°

ELBOW

90°

ELBOW

RODENT SCREEN

(INSTALL INTO

ELBOW)

Figure 8 General Venting Layout

TERMINATION

ELBOW

GROUND LEVEL OR

MAXIMUM SNOW

LINE*

WATER

HEATER

MODEL

SUFFIX

VENT PIPE

SIZE

PRESSURE

SWITCH

SETTING

* VENT

MATERIAL

(SCHEDULE 40)

MAXIMUM EQUIVALENT

VENT LENGTH

MINIMUM EQUIVALENT

VENT LENGTH

G/JW75

SNV,

SPV

76mm (3 in.)

- 0.50 in. w.c.

(-.124 kPa)

PVC**, CPVC

15.2m (50 ft.) +

termination elbow with

steel mesh screen

0.91m (3 ft.) + one 90°

elbow + termination elbow

with plastic screen

Notes:

1. Each 76mm (3 in.), 90° elbow is equivalent to 2.44m (8 ft.) of vent length.

2. Each 76mm (3 in.), 45° elbow is equivalent to 1.22m (4 ft.) of vent length.

3. Use long radius elbows. Minimum distance between elbows is 150mm (6 in.).

4. Do not mismatch venting materials. *Check local codes to determine which materials are allowed in your area.

5. **Pipe assembly adapter must be used with PVC venting material (see Figure 13).

Table 2 Allowable Vent Lengths and Materials (Vert. and Horiz.).