Bell & Gossett V57083D Diaphragm Expansion Tanks ASME And Non-Code User Manual

Page 4

SERVICE INSTRUCTIONS

1. Check the expansion tank periodically for signs of external

leakage or corrosion. If found, the tank must be replaced.

WARNING: Signs of leakage or corrosion are

indications the tank may fail. Periodically check the

expansion tank for signs of external leakage or corrosion.

If found, the tank must be replaced. Failure to follow these

instructions will result in serious personal injury or death

and property damage.

2. If a HVAC system is shut down for long periods or emptied

for any reason, it is necessary to follow the following proce-

dure:

a) Fill system.

b) Vent air from system (see system venting and purging).

c) Bring system up to maximum operating temperature.

3. If the system pressure is too high:

a. Check gauge calibration.

b. Check to see if expansion tank has lost its air charge.

Note: To check the expansion tank air pressure with a

tire gauge either:

1. Disconnect the expansion tank from the system or,

2. Draw off system water until boiler pressure reads

zero or isolate the expansion tank from the system

in domestic water systems, and bleed pressure

from the system. All drains must be kept open during

servicing of expansion tank. (Expansion tank must be

empty of expanded system water.)

3. Then check tank pressure with tire air gauge.

WARNING: Improper use of air charging valve

during venting of air pressure from tank will create a

hazardous condition due to the escape of high velocity

gas and/or liquid. Depress the center valve core stem,

as with a tire valve to slowly vent off gas pressure. Do

not remove the valve core until pressure in the expansion

tank has reached zero. Failure to follow these instructions

could result in serious personal injury or death and

property damage.

c. Check for faulty fill valve operation. First, close manual

shut-off located before the fill-valve; then, draw system

pressure down to pre-set pressure (see TABLE 1) open

shut-off valve and observe system for pressure build-up

several hours later. If pressure build up beyond set pres-

sure is found, replace fill valve following manufacturers

instruction.

d. Check for service water entering system from any other

source such as a defective tankless heater or indirect

fired water storage tank. Use same procedure as above

after shutting off possible water source. Replace defec-

tive device if found following manufacturers instruction.

4. If pressure relief valve drips water:

a. First, check system pressure. If too high, follow steps 3.

a., b., c. and d. above.

b. If pressure relief valve continues to drip water, even at

reduced pressure, flush relief valve by quickly raising

lever several times. If drip continues, replace relief valve

following manufacturers instruction.

c. If multiple expansion tanks are installed in the system,

check pressure of each for possible air leaks. Be sure

plastic air valve caps are on tight. Multiple tanks should

be in the same location.

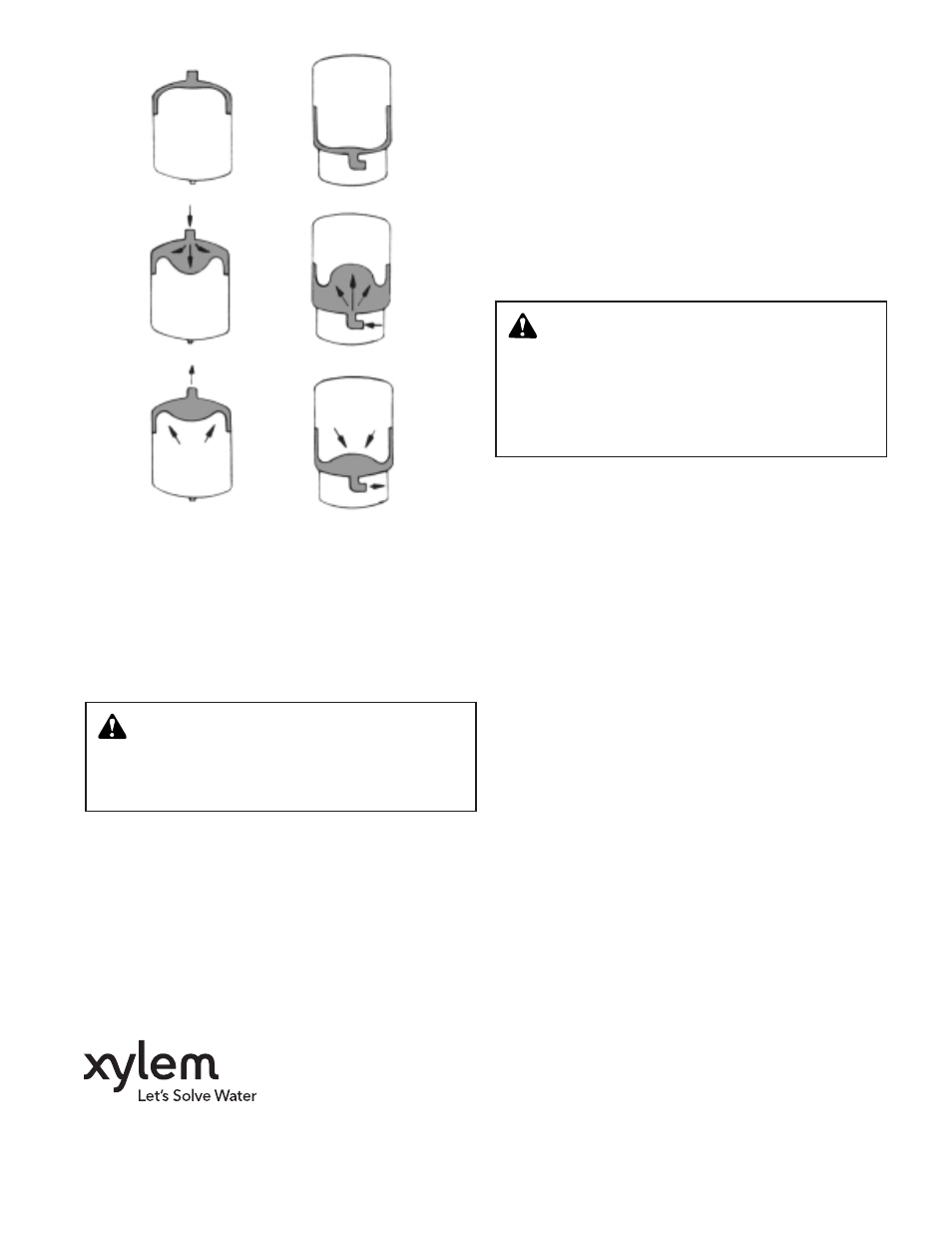

AIR

CUSHION

AIR

CUSHION

MODELS

PT-5 & PT-12

PTA-5 & PTA-12

HFT-15 THRU HFT-90

WTX-2 THRU WTX-14

MODELS

PT-25V & PT-457

PTA-20V & PTA-457

HFT-30V THRU HFT-160V

ALL WT & WTA MODELS

WTX-10S THRU WTX-119S

AIR

CUSHION

AIR

CUSHION

AIR

CUSHION

AIR

CUSHION

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. V57083D May 2012