System venting and purging, Operating instructions – Bell & Gossett V57083D Diaphragm Expansion Tanks ASME And Non-Code User Manual

Page 3

C. Installation ( “HFT” Series)

The series “HFT” may be installed into a tee or any other suit-

able tapping on a water heating system, preferably on the

suction side of the circulator. (see Figure 2).

SYSTEM VENTING AND PURGING

(For hydronic heating systems not

potable water systems)

After initial venting and purging of air from the system, more

air will be released from the water as it is heated. Therefore, it

is recommended that a B&G air separator be installed on the

main.

If the system has multiple loops or zones, the supply water for

all loops and zones must pass through the air separator for

complete and continuous air removal. In case the piping

arrangement does not permit the installation of a single air

separator on the main, air separators should be installed on

each loop or zone. In this event, only one expansion tank is

required for the system.

Even with a B&G air separator installed on the main or mains,

it is recommended that B&G air vents be installed on high

points in the system.

It is also recommended that manual (key or coin type) air

vents be installed at higher points on the radiation.

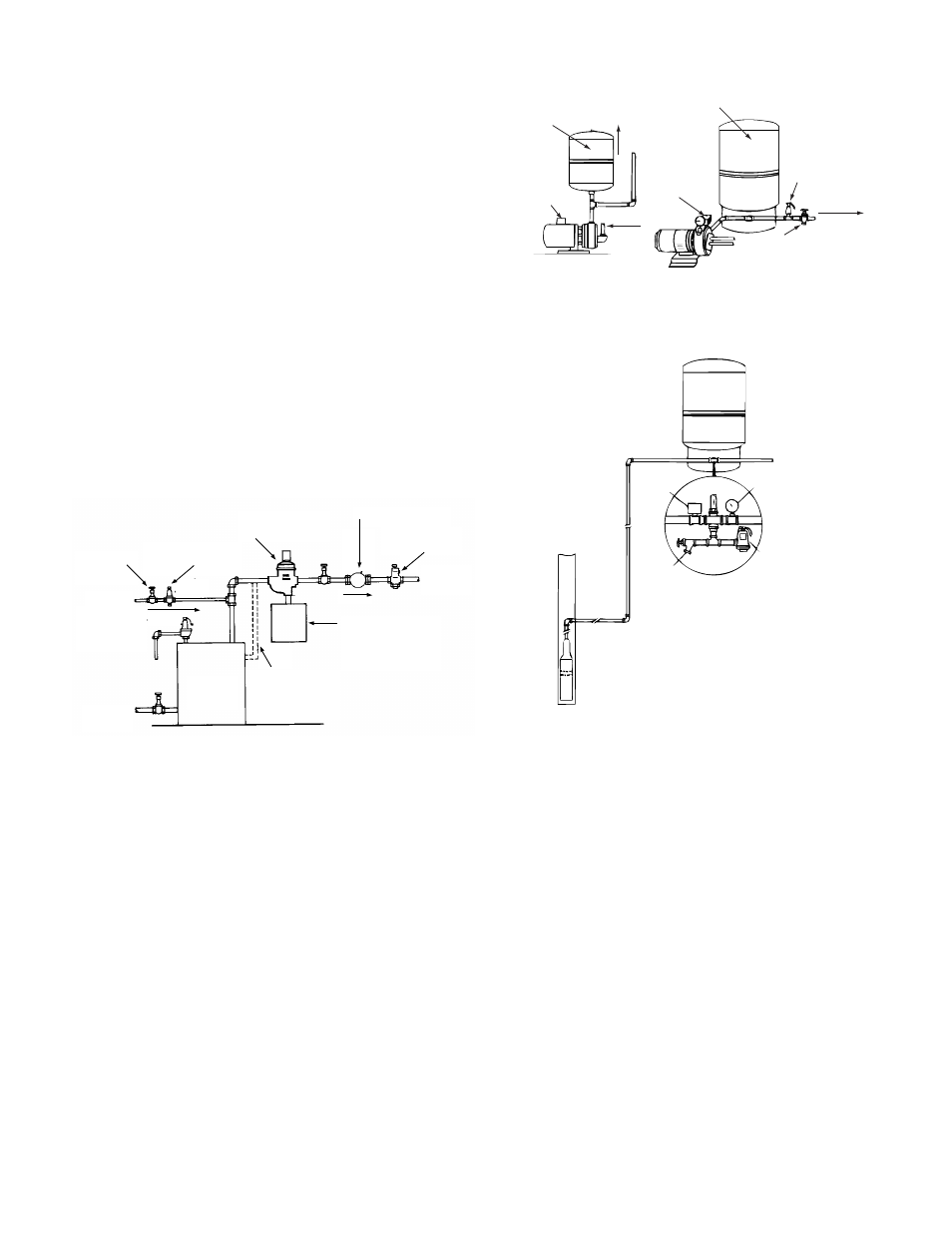

D. Installation ( “WTX”, “WT” & “WTA” Series)

The well tank should be installed as close as possible to the

pressure switch. Inline models are generally installed directly

into the main water supply with a

3

/

4

" connection. The floor

models are generally installed using a tee off main. (See fig-

ures 3 & 4.) The air pressure should be adjusted to 1-2 PSIG

below the pressure switch pump “cut-in” setting. (Tank should

be at room temperature and empty of water when adjusting

the air pressure.) Refer to Table 1 for the factory pre-charge

pressure.

System Connection

1. Locate desired tank location.

2. Level the tank as necessary.

3. Connect to pump supply line with the same size pipe as

from pump.

4. All piping should be in accordance with local code require-

ments

OPERATING INSTRUCTIONS

1. The expansion tank’s sealed-in-air pre-charge prevents

water from entering the tank until the system pressure

exceeds the pre-charge pressure.

2. As the water temperature rises, expanded water enters the

expansion tanks water reservoir. The pre-charged air

chamber absorbs the pressure increase, keeping system

pressures below the relief valve setting.

3. As water is used in a potable well system, the pressure in

the air chamber forces water back into the system until the

pressure switch pump “cut-in” setting is reached. The

pump will then turn on forcing water into the tank until the

pump “cut-out” pressure is reached. The water stored in

the tank is supplied to the potable water system under

pressure without the pump turning on.

3

TYPICAL INSTALLATION

FIGURE 2

B&G PRESSURE

REDUCING VALVE

CW FILL

SHUT-OFF

VALVE

B&G RELIEF

VALVE

DIAPHRAGM TYPE

EXPANSION TANK

“HFT”

B&G BOOSTER

FLO-CONTROL

B&G

VALVE

TO

SYSTEM

BOILER

RETURN

OPTIONAL SIDE

OUTLET BOILER

CONNECTION

AIR SEPARATOR

FLOW

INLINE

WELL

TANK

TO SYSTEM

PRESSURE

SWITCH

FROM WELL

FLOOR

MOUNT

WELL

TANK

RELIEF VALVE

TO SYSTEM

DRAIN

PRESSURE

SWITCH

TO WELL

TANK

PRESSURE

GAUGE

RELIEF

VALVE

DRAIN

PRESSURE

SWITCH

SUBMERSIBLE

PUMP

INSTALLATION WITH JET PUMP

FIGURE 3

INSTALLATION WITH SUBMERSIBLE PUMP

FIGURE 4