Piping, Wiring, Nrf-vs control installation – Bell & Gossett P86271B Variable Speed NRF-VS Control with setpoint or external signal follower User Manual

Page 4

PIPING

PIPING OVERVIEW

•

The Primary loop may have mulitple injection loops or other

takeoffs. However, the piping for each injection system

must meet the requirements described below.

• The Injection piping can be installed in either a horizontal or

a vertical configuration.

• The pipe diameters of the Primary and Secondary loops

may differ.

• The Injection Piping diameter must be at least one pipe size

smaller than the smaller of the Primary and Secondary loop

piping. For example, if the Primary loop diameter is 1

1

/

4

"

and the Secondary loop diameter is 1", then the diameter of

the Injection piping must be

3

/

4

" or smaller.

• The Injection pump motor must be a fractional B&G NRF,

NBF or SSF permanent split capacitor type pump. (Refer to

operational limits on Page 2 for pump information.) The

Injection pump will control the amount of water pumped

from the Primary loop into the Secondary loop.

• A balancing valve should be installed on the injection return

piping. This helps to balance the system.

• The distance between the injection tees should be as short

as possible. The rule of thumb distance between the tees is

3 times the pipe diameter. For instance, if the pipe diameter

is 1" then the length of straight pipe between the two

injection tees should be 3".

HORIZONTAL PIPING CONFIGURATION

•

The Injection piping can be installed horizontally as shown

in Fig. 2.

• The Injection supply piping should run horizontally from the

Primary to the Secondary loop.

• On the Injection piping it is necessary to install a heat trap

to prevent heat from the Primary loop entering the Secon-

dary loop when the Injection pump is not running.

• The injection piping must drop down vertically at least 18"

and then rise back up vertically at least 18".

VERTICAL PIPING CONFIGURATION

•

The Injection piping can be installed vertically.

• The Primary loop must be at least 18" vertically above the

Secondary loop.

INSTALLING SENSOR

•

In a primary/secondary application, the secondary loop

sensor should be mounted downstream of the inlet loop and

before any major heating units. That will provide the control

a more accurate temperature reading (Refer to Fig. 2.)

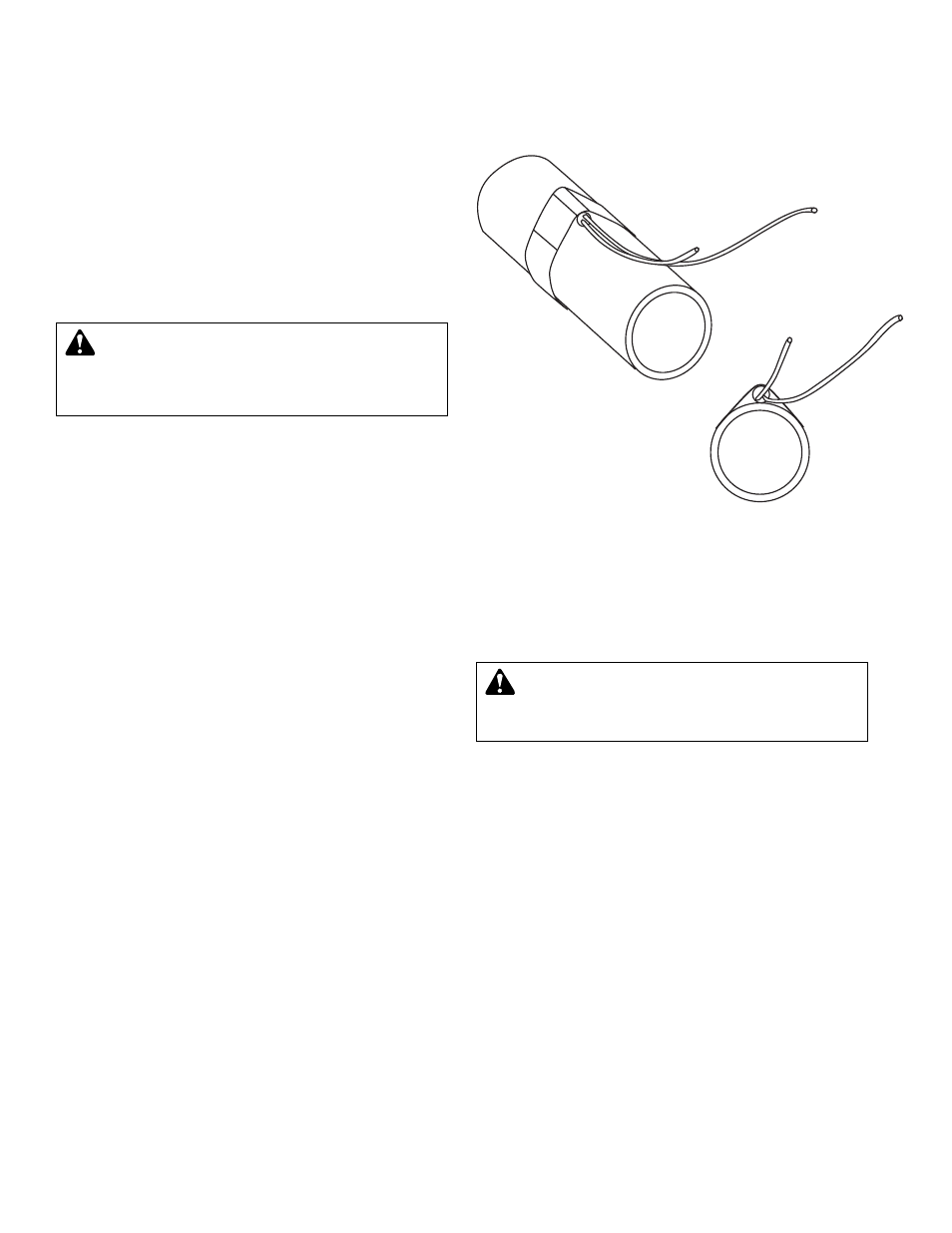

• Strap the cylindrical sensor to the pipe as shown in Fig. 3.

• Wrap the pipe and sensor assembly with insulating tape to

insure adequate heat transfer to the sensor.

• The sensor wires can be extended up to 500' from the

controller. If the sensor wires are located in an area with

strong sources of electro-magnetic interference (EMI), the

wires must be run in a grounded metal conduit. Do not run

wires in conduit with line voltage.

WIRING

NOTE:

If the NRF-VS control is already installed on the pump,

skip the NRF-VS control installation section and proceed to

the “wiring the sensors” section.

NRF-VS

CONTROL INSTALLATION

1.

Disconnect the electrical supply to the pump.

2. Remove the screw that holds the steel conduit box cover

to the pump.

3. Remove the conduit box cover. The NRF-VS control

assembly replaces the conduit box cover.

4. Disconnect the black and white motor leads from the

power supply.

5. Position the plastic base for the NRF-VS control

assembly onto the steel conduit box with the warning/

caution label to the rear of the pump.

6. Secure the plastic base to the conduit box with one 8-32

screw provided.

7. Verify that the electrical rating of the NRF-VS control

matches the values shown on the nameplate of the

circulator.

WARNING: ELECTRICAL SHOCK HAZARD

Disconnect and lock out power before making elec-

trical connections. Failure to follow these instructions could

result in serious personal injury or death.

4

CAUTION: The Injection pump and pipe sizing

should be performed by a qualified engineer or

contractor. Failure to follow these instructions could

cause inadequate system performance and/or property

damage.

FIG. 3