Opera tion, Design selectio n – Bell & Gossett P86271B Variable Speed NRF-VS Control with setpoint or external signal follower User Manual

Page 3

OPERA

TION

The NRF-VS is designed to control the pump speed on an

injection system allowing the pump to inject a different water

temperature into a secondary loop to regulate its temperature.

It can be used either in heating or cooling applications using a

secondary loop temperature sensor. The sensor reads the

secondary loop temperature allowing the NRF-VS to regulate

the loop temperature by modulating the injection pump speed

accordingly to reach a set point.

A temperature knob mounted on the NRF-VS is used to adjust

the temperature set point either in heating or cooling (see Dip

Switch 2). Dip Switch 1 must be set to ON to activate the Set

Point feature. The sensor must be wired to terminals 2 and 3

when using the setpoint mode.

The NRF-VS can be controlled remotely using an external

signal to replace the set point. This allows for the external

control or system providing the input to change the pump

speed directly. No sensor is required in this setting. The

external input providing either 4-20mA signal or 2-10V signal

must be wired to terminals 1 and 2. The speed of the pump

will vary from full stop below 4mA or 2V to 100% at 20mA or

10V. Dip switch 1 must be set OFF to activate the external

signal feature.

DESIGN SELECTIO

N

To select the correct pump, pipe size and balance valve:

1. Determine the Primary Loop Temperature. This is the

temperature the primary loop will maintain.

2. Determine the Secondary Loop Temperature. This is the

design temperature of the secondary loop. If an outdoor

reset function is being employed, this is the required

temperature of the secondary loop under maximum load.

3. Determine the design temperature drop (

᭝T or delta T) of

the secondary loop. This is the design drop in tem-

perature through the secondary loop. In most radiant

heat applications,

᭝T is 10. Other types of radiation such

as baseboard have a higher design

᭝T.

4. Determine the Maximum Injection Heat Load. This is the

maximum heat requirement of the secondary loop. The

maximum injection heat load is based on the injection

pump running at the highest speed. As the pump speed

is reduced, less heat will be delivered to the secondary

loop.

5. Use the equation below to determine the design injection

flow rate.

Design Injection Flow Rate (GPM) =

Maximum Injection Heat Load (BTU/hr)

500 (T

primary

- T

secondary

+

᭝T

secondary

) (ºF)

6. Use the table below to select the appropriate pump, pipe

size and balance valve.

Design Injection

Injection B&G Circuit

Setter

®

B&G Circuit Setter

®

B&G

Flow Rate (GPM)

Pipe Size

Balance Valve

Valve Setting

Pump

1.5

1

/

2

"

CB-

1

/

2

/ CB-

1

/

2

S

18 / 25

NRF-22

3.5

1

/

2

"

CB-

1

/

2

/ CB-

1

/

2

S

full open / 6

NRF-22

6

3

/

4

"

CB-

3

/

4

/ CB-

3

/

4

S

full open / 12

NRF-22

10

1"

CB-1 / CB-1S

full open / full open

NRF-22

15

1

1

/

4

"

CB-1

1

/

4

/ CB-1

1

/

4

S

5 / 5

NRF-22

Example:

1. Primary Loop Temp: 140ºF

2. Secondary Loop Temp: 100ºF

3. Design temperature drop: 10ºF

4. Maximum injection heat load: 150,000 BTU/hr

5. Calculate Injection flow rate

Design Injection Flow Rate (GPM) =

150,000 (BTU/hr)

=

150,000

= 6 GPM

500 (140 - 100 + 10) (ºF) 25,000

6. Injection Pipe size is

3

/

4

", full open CB-3/4 balancing valve and NRF-22

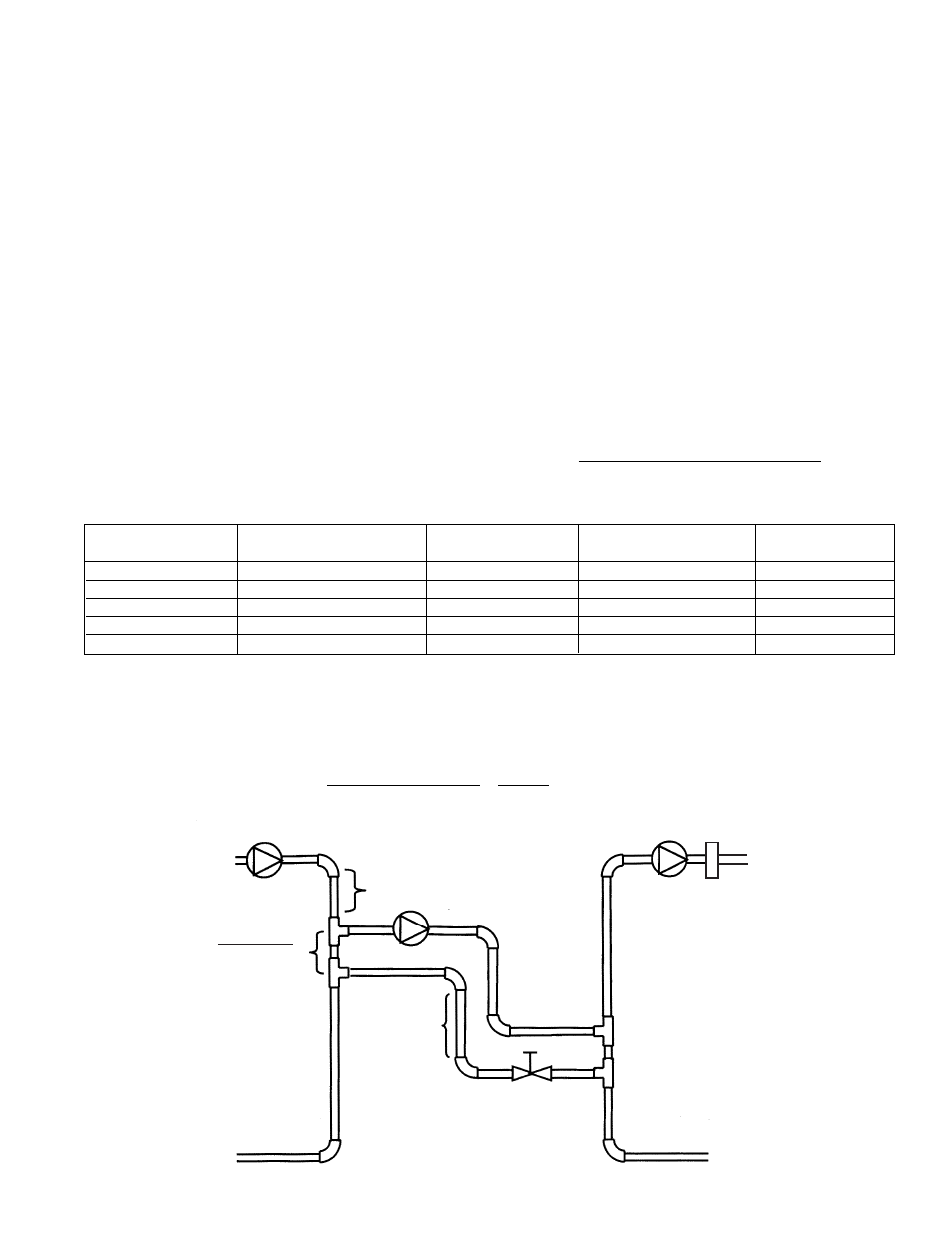

Minimum of 1' of

pipe drop required

to create a thermal

trap

Rule of Thumb

3 pipe diameters

between tees

Minimum of 8 pipe diameters upstream

and 4 pipe diameter downstream of straight

pipe on either side of tees to prevent any

possibility of “jet flow” through the

common piping.

Secondary

Loop

Secondary

Loop Pump

Primary

Loop Pump

Secondary

Loop Sensor

Primary

Loop

Injection Pump

Balance

Valve

3

FIG. 2

Based on (5) feet of pipe, (4) 90

° elbows, (4) tees. Correct pipe and pump size calculation for any application should be performed by a qualified engineer or contractor.