2 night set back mode, 3 ∆p-t control, 4 t-constant temperature control – Bell & Gossett P2002548B ecocirc XL High Efficiency Large Wet Rotor Pumps User Manual

Page 11: 5 ∆p-∆t control, 6 ∆t constant, 7 external start/stop, 8 analog input, 9 signal relay, 10 external sensors (optional)

Mode

Description

Proportional pressure

2

Hset

Hset

The pump pressure is continuous-

ly increased/decreased depend-

ing on the increased/decreased

flow demand. The maximum head

of the pump can be set via user in-

terface. See section 6.1.2 Change

set point.

Fixed speed control

Max

min

Speed

setpoint

The pump maintains a fixed speed

at any flow demand. The speed of

the pump can be set via user inter-

face. See section 6.1.2 Change set

point.

All the above control modes can be combined with the night mode

function.

5.2.2 Night set back mode

The night set back mode cannot be used in cooling systems.

Prerequisite

• The pump is installed between boiler outlet and system supply.

• The night set back feature is initiated when the pump recognizes a

water temperature change brought about by the boiler or high

level control system.

The night set back mode is active only in combination with:

• Proportional pressure

• Constant pressure

• Constant speed

This function reduces power consumption of the pump to the minimum

when heating system is not running. An algorithm detects the water

temperature change and automatically adjusts the speed of the pump.

The pump returns to the original set point as soon as the system re-

starts.

5.2.3 ∆p-T control

This function adjusts the nominal differential pressure set point accord-

ing to the temperature of the pumped media.

For details refer to advanced functions manual on www.bellgos-

sett.com

5.2.4 T-Constant temperature control

This functional mode changes the speed of the pump in order to main-

tain a constant temperature of the pumped media. It is suitable for

heating systems with fixed system characteristics, for example Domes-

tic Hot Water Systems.

For details, refer to the advanced functions manual on www.bellgos-

sett.com

5.2.5 ∆p-∆T control

This function requires the external temperature probe type KTY83 (see

section 5.2.10 of this manual).

This function adjusts the nominal differential pressure set point de-

pending on the differential temperature of the pumped media. An ex-

ternal temperature sensor Type: KTY83 is required for this functionality

(see section 5.2.10 of this manual for details).

For details, refer to the advanced functions manual on www.bellgos-

sett.com

5.2.6 ∆T constant

This function alters the speed of the pump in order to maintain a con-

stant differential temperature of the pumped media.

For details, refer to the advanced functions manual on www.bellgos-

sett.com

5.2.7 External start/stop

The pump can be started or stopped via an external dry contact or a

relay that is connected to terminals 11 and 12. The pump unit is provid-

ed by default, with the terminals 11 and 12 jumpered. See Figure 4 on

page 8.

NOTICE:

• The pump provides 5 VDC through the start / stop terminals.

• No external voltage must be provided to start / stop terminals.

• The cables connected to terminals 11 and 12 shall not exceed 65

feet in length.

5.2.8 Analog Input

The pump integrates a 0-10 V analog input at terminals 7 and 8. See

terminal diagram figures for changing the setpoint. See Figure 4 on

page 8.

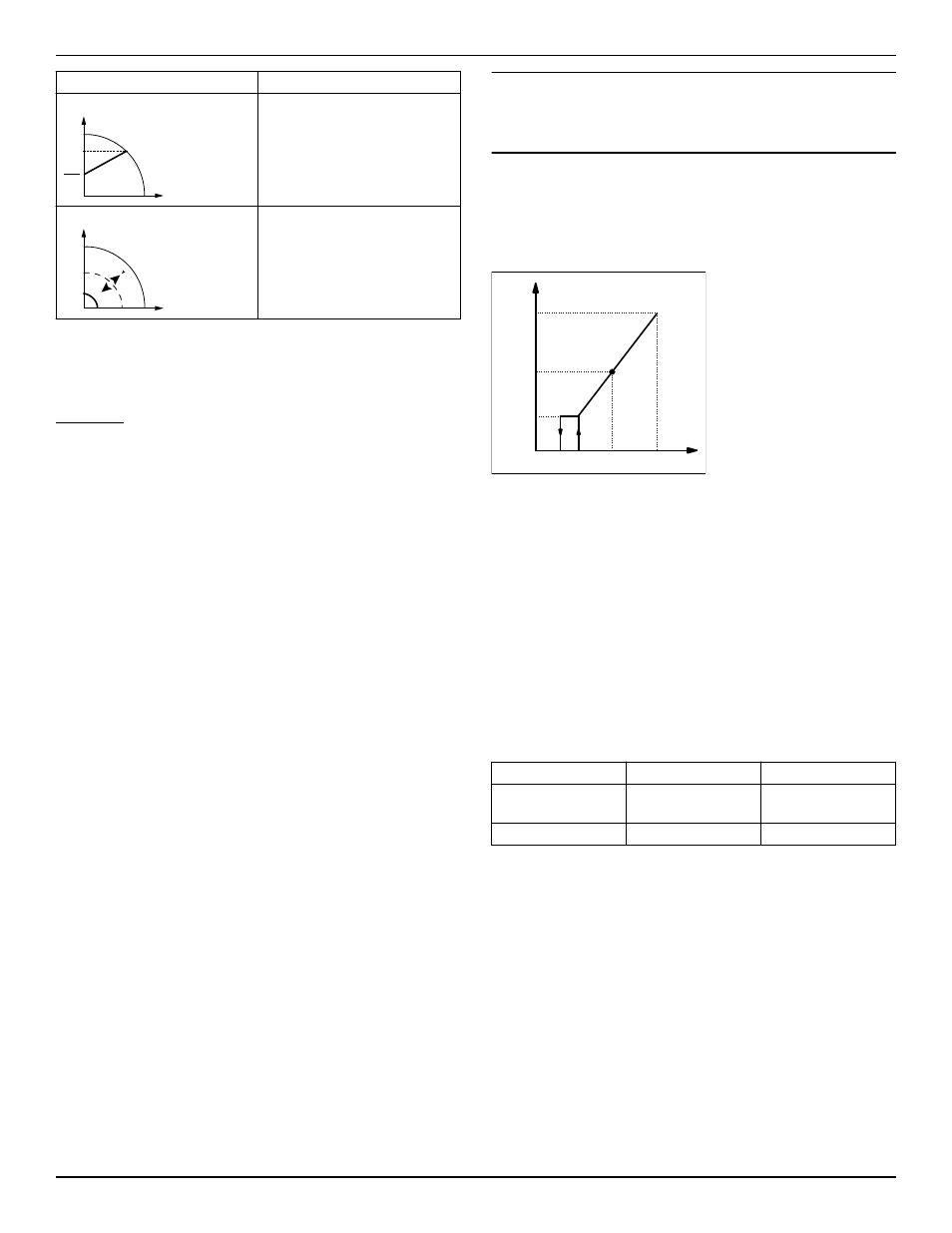

When a voltage input is detected, the pump switches to fixed speed

control mode automatically and starts to run according to the following

diagram:

Vin[V]

Speed

[rpm]

Vset

10

1.5

1.2

min

Max

Setpoint

Figure 6: Voltage input detected

Pump stops at 1.2 V

Pump restarts at 1.5 V

5.2.9 Signal relay

A dry contact relay is provided at terminals 4 and 5. See connection di-

agram, figure 4 on page 8, for location. If there is a fault, the relay con-

tact closes to display a red status light and the error code on the user

interface display. See

(page 8). The relay contact closure

can also be used to energize a remote fault display.

Ratings

• Voltage: 115/208 – 230/1

• Imax < 2 A

5.2.10 External sensors (optional)

The pump can be equipped with a differential pressure sensor and a

temperature sensor according to the following table:

Sensor description

Type

Terminals

Differential pressure

sensor 4-20mA

15 PSI

30 PSI

9 - 10

Temperature sensor

KTY83/121

13 - 14

Pressure sensor setup

1.

Install pressure sensor on the pipe

2.

Connect wires at terminals 9 and 10. See Figure 4 on page 8.

3.

Power the pump on.

4.

Upon startup, the pump detects the sensor and displays the setup

menu.

5.

Select the right sensor model and confirm the selection using the

parameter button (3). See

6.

The pump will run through the startup sequence and automatical-

ly start working in constant pressure mode.

7.

The setpoint can be changed using the settings button (5). See

External temperature sensor setup

The external temperature sensor setup and related control modes are

available only through RS-485 or wireless module connection.

For details refer to advanced functions manual on www.bellgos-

sett.com

5 System Description

ecocirc XL Installation, Operation, and Maintenance manual

9