6 change the position of the motor housing, 7 electrical installation, 1 power supply connection – Bell & Gossett P2002548B ecocirc XL High Efficiency Large Wet Rotor Pumps User Manual

Page 9

• Only use the pump thermal shells that are included in the de-

livery. Do not insulate the motor housing, the electronics can

overheat and cause the pump to thermally overload.

• The thermal shells that are included with the pump must only

be used in hot water circulation applications with fluid tem-

perature above 68°F (20°C). The thermal shells are permea-

ble to water vapor.

• If the customer installs the vapor barrier insulation shells for

cold water application, then the pump housing must not be

insulated above the motor flange. The drain opening must

be kept unobstructed in order that the accumulated conden-

sation can run out.

4.6 Change the position of the motor

housing

WARNING:

• Drain the system if possible or close the service valves

on both sides of the pump before disassembling the

pump. The pumped fluid can be pressurized and may

be scalding hot.

• There is the risk of escaping vapor when the motor is

separated from the pump housing.

Electrical Hazard:

Before starting work on the unit, make sure that the unit and

the control panel are isolated from the power supply and

cannot be energized.

CAUTION:

Burn hazard. During operation various surfaces on the unit

will become hot. To avoid burn injury, use heat protective

gloves.

WARNING:

• A strong magnetic field is created when the rotor is re-

moved from or inserted into the motor housing. This

magnetic field can be harmful to pacemaker wearers

and others with medical implants. In addition, the mag-

netic field may attract metal parts to the rotor which can

cause injuries and/or damage the bearing of the pump.

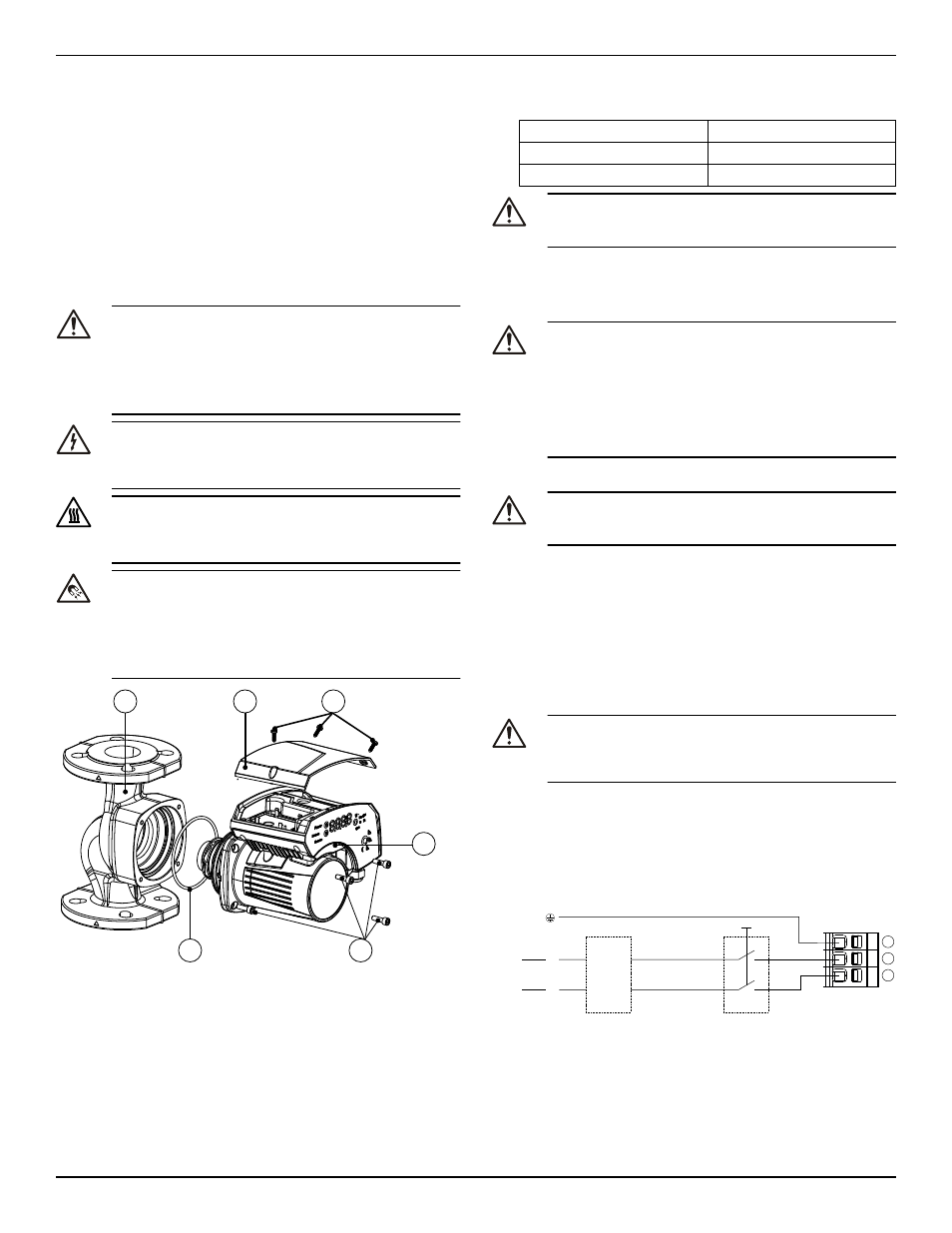

3

2

4

6

5

1

Figure 2: Change the position of the pump head

1.

Loosen the four hex-head screws (2) that fix the motor to the

pump housing (4) using the T-handle allen wrench described.

2.

Rotate the motor (1) in 90° steps to the desired position.

3.

In case of separation of the motor housing from the pump body

(4):

a)

avoid removing the rotating assembly from motor housing;

b)

pay attention to the magnetic hazard listed before.

A defective O-ring must be replaced. An O-ring is already availa-

ble inside the package as spare part.

4.

Properly align and tighten the four hex-head screws (2) that affix

the motor to the pump body (4) according to the torque table giv-

en below in a criss cross pattern.

M6

90 in-lb

M8

170 in-lb

M10

340 in-lb

CAUTION:

Check for the presence of leaks after reassembling the

pump.

4.7 Electrical installation

Precautions

WARNING:

• Make sure that all connections are performed by a quali-

fied electrician in accordance with all applicable codes,

ordinances and good practices. Failure to follow these

instructions could result in serious injury, death and/or

property damage.

• Before starting work on the unit, make sure that the unit

and the control panel are isolated from the power sup-

ply and cannot be energized.

Grounding (earthing)

WARNING:

Reduced risk of electric shock during operation of this pump

requires the provision of acceptable grounding.

Be sure the following are adhered to. Failure to follow these instruc-

tions could result in serious personal injury, death, and/or property

damage.

• If means of connection to the supply connection box (wiring com-

partment) is other than grounded metal conduit, ground the

pump back to service using a copper conductor at least the size of

the circuit conductors supplying the pump.

• Connect the ground wire to the green grounding terminal in the

wiring compartment.

4.7.1 Power supply connection

WARNING:

Do not make any connection in the pump control box unless

the power supply has been switched off for at least 2 mi-

nutes.

For models with standard terminal block connection:

1.

Open the terminal box cover removing the screws (5).

2.

Thread the ½” NPT electrical fitting into the conduit connection of

the pump.

3.

Connect the cable according to the wiring diagram.

a.

Connect the ground wire, if used.

b.

Connect the wires.

4.

Close the terminal box cover.

1

2

3

L

N

115V

L

1

L

2

208-230V

CB

Figure 3: Wiring diagram

4 Installation

ecocirc XL Installation, Operation, and Maintenance manual

7