3 fault and error codes, 4 alarm codes, 5 faults, causes, and remedies – Bell & Gossett P2002548B ecocirc XL High Efficiency Large Wet Rotor Pumps User Manual

Page 14

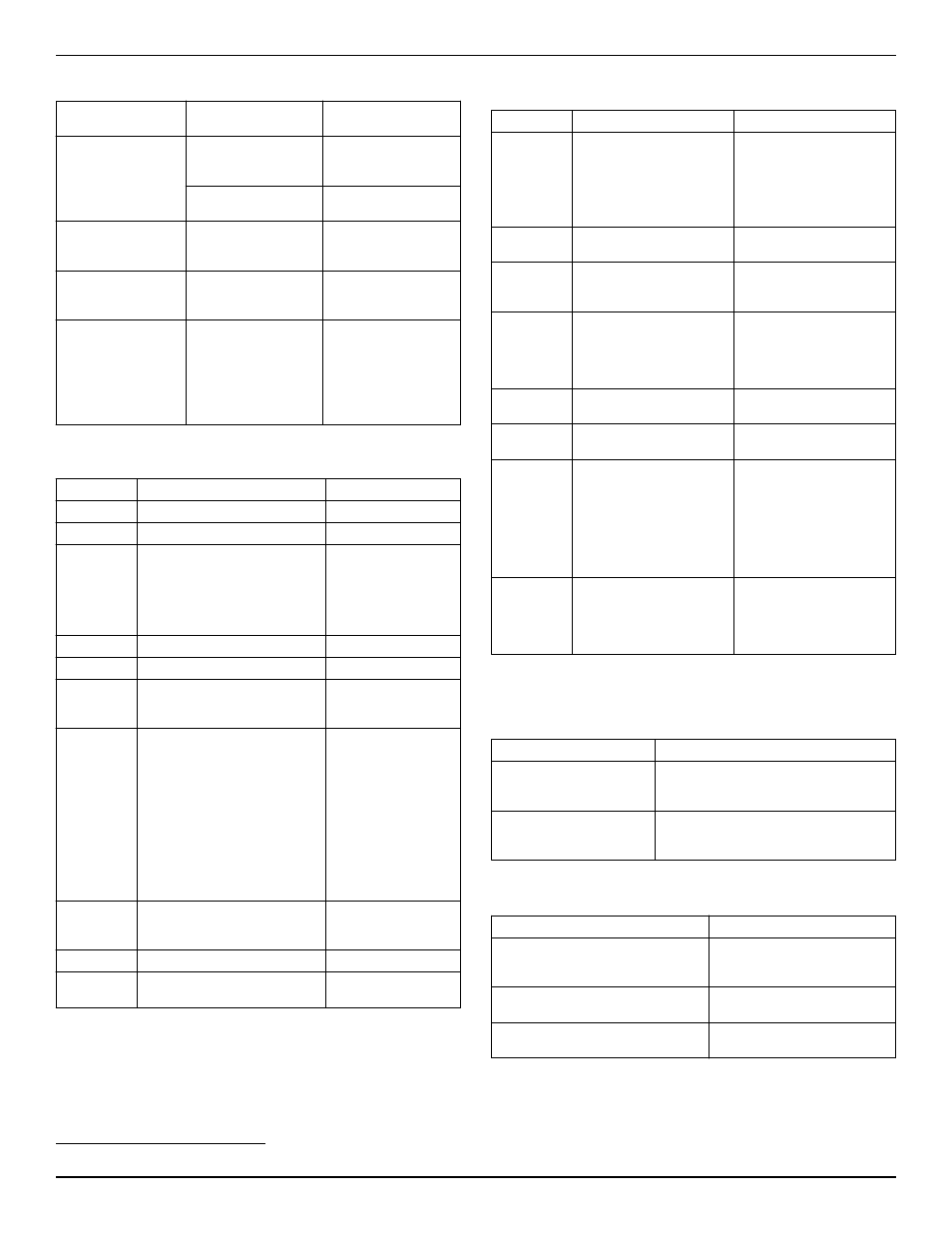

Table 2: Fault messages

Operating LEDs / Dis-

play

Cause

Solution

Power Off

Pump is not connected

or is incorrectly con-

nected

Check connection

Power failure

Check power supply

and circuit breaker

Status light Orange

Alarm for system prob-

lem

Check the displayed

alarm code and find

cause from table 8.3.

Status light Red

Pump failure

Check the displayed

error code and find the

cause from table 8.2.

Remote Off

Remote communica-

tion is deactivated

If the communication

does not work, check

the connection and the

configuration parame-

ters for communication

on the external con-

troller.

8.3 Fault and error codes

Error code

Cause

Solution

E01

Internal communication lost

Restart the pump

2

E02

High motor current

Restart the pump

2

E03

DC Bus overvoltage

Indicates excessive

power through the

pump. Confirm system

setup, verify correct

position and opera-

tion of check valves.

E04

Motor stall

Restart the pump

2

E05

Data memory corrupted

Restart the pump

2

E06

Voltage supply out of operating

range

Check the electrical

system voltage and

wiring connection.

E07

Motor thermal protection trip

Check the presence of

foreign material

around impeller and

rotor that cause over-

load. Check installa-

tion conditions and

temperature of the

water and ambient air.

Wait until the motor is

cooled. If the error

persists try to restart

the pump

2

.

E08

Inverter thermal protection trip Check installation con-

ditions and ambient

air temperature.

E09

Hardware error

Restart the pump.

E10

Dry run

Check for system leak-

age or fill the system.

8.4 Alarm codes

Alarm code

Cause

Solution

A01

Fluid sensor malfunction

Switch off the pump for 5

minutes and then power

on.

If the problem persists,

contact local B&G repre-

sentative.

A02

High temperature of the

fluid

Check water temperature

value

A03

Automatic speed reduction

to prevent inverter over-

heating

Check installation condi-

tions and rectify status of

the system

A05

Data memory corrupted

Switch off the pump for 5

minutes and then power

on. If the problem persists,

contact local B&G repre-

sentative.

A06

External temperature

probe malfunction

Check the probe and the

connection to the pump

A07

External pressure sensor

malfunction

Check the sensor and the

connection to the pump

A12

2–pump communication

lost

If both pumps show the

A12 alarm, check the con-

nection between the

pumps. If one of the pump

is switched off or shows an-

other error code, check the

section 8.1 and 8.2 to find

the problem

A20

Internal alarm

Switch off the pump for 5

minutes and then power

on. If the problem persists,

contact local B&G repre-

sentative.

8.5 Faults, causes, and remedies

The pump does not start

Cause

Remedy

No power.

Check the power supply and ensure that

it is properly terminated to the pump

power.

Tripped circuit breaker or

ground-fault protection de-

vice or the circuit breaker.

Reset power supply circuit breaker and

determine cause for overload.

The pump starts but the thermal protection is triggered after a short

time

Cause

Remedy

Incorrect wiring size or circuit break-

er rating not suitable for motor cur-

rent.

Check and replace the compo-

nents as necessary.

Thermal overload protection due to

excessive input.

Check the pump working con-

ditions.

Missing a phase in the power supply. Verify continuity and ensure

proper wiring connections.

2

Switch off the pump for 5 minutes and then power on. If the problem persists, contact service.

8 Troubleshooting

12

ecocirc XL Installation, Operation, and Maintenance manual