Mounting – MJK Automation Shuttle Ultrasonic Level Transmitter and Sensor User Manual

Page 7

7

SW 838023

GB Shuttle Manual 100316

Mounting

Mounting

General

Shuttle

®

measures the level by sending an

ultrasonic signal against the surface and

measuring the delay time of the received

echo.

Although Shuttle

®

is equipped with a very

advanced system for eliminating measur-

ing errors, the ultrasonic sensor must - as

much as possible - be mounted so that the

ultrasonic signal is not disturbed by liquid

being pumped in or by mixers, ladders or

other installations in the tank.

The liquid surface should also be calm and

without waves and possibly without foam

that may muffle the ultrasonic echo too

much.

Since the ultrasonic beam is extremely

narrow (between 3 - 7 ° depending on

the sensor type), Shuttle

®

can be used for

measurements in very narrow tanks or wells.

This requires that the ultrasonic sensor is

mounted so it points absolutely vertical

against the surface - or the ultrasonic echo

will simply miss the sensor.

Explosion hazardous areas

The ultrasonic sensor is Ex approved in

accordance with EN 50021:1999 and can

be mounted in Zone 2 without the need of

a zener barrier. Please check local require-

ments before installing in hazarduous

locations.

The level transmitter (= the electronic

box with display) must not be mounted in

explosive hazardous areas.

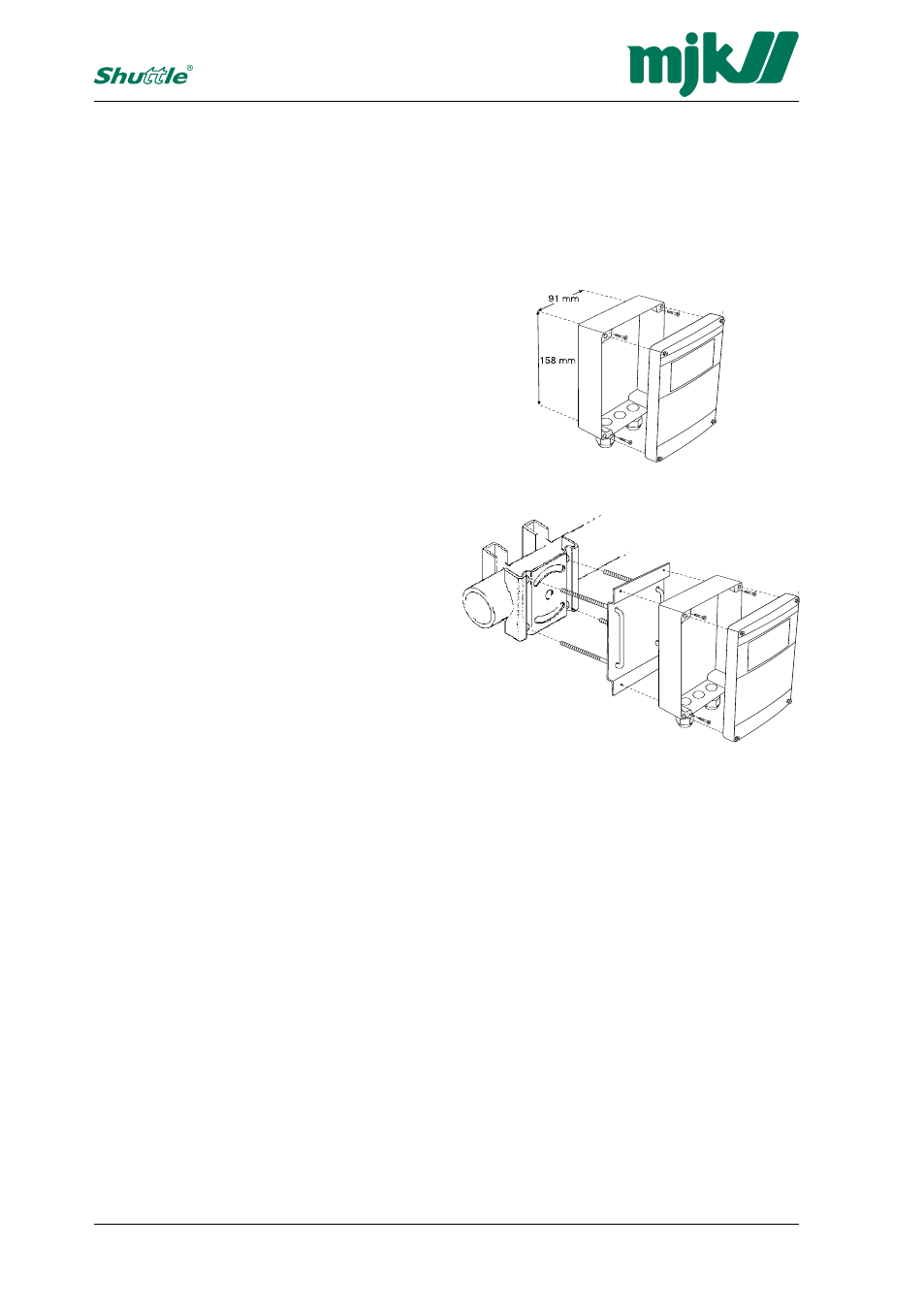

Mechanical mounting

Level transmitter

Shuttle

®

is in IP65 enclosure and can be

mounted outdoors directly on a wall, a

railing or a banister with mounting plate

200240 and universal bracket 200205.

Shuttle

®

Ultrasonic Level Transmitter

mounted directly on a wall.

Shuttle

®

Level Transmitter mounted on the plant

with mounting plate 200240 and universal bracket

200205.

Shuttle

®

must be mounted

vertically in order to observe the

NEMA4X standard.