Bell & Gossett HS 600D Pilot Mounting Hardware Kits Series 2000 Pressure and/or Temperature Steam Regulators User Manual

Page 3

3

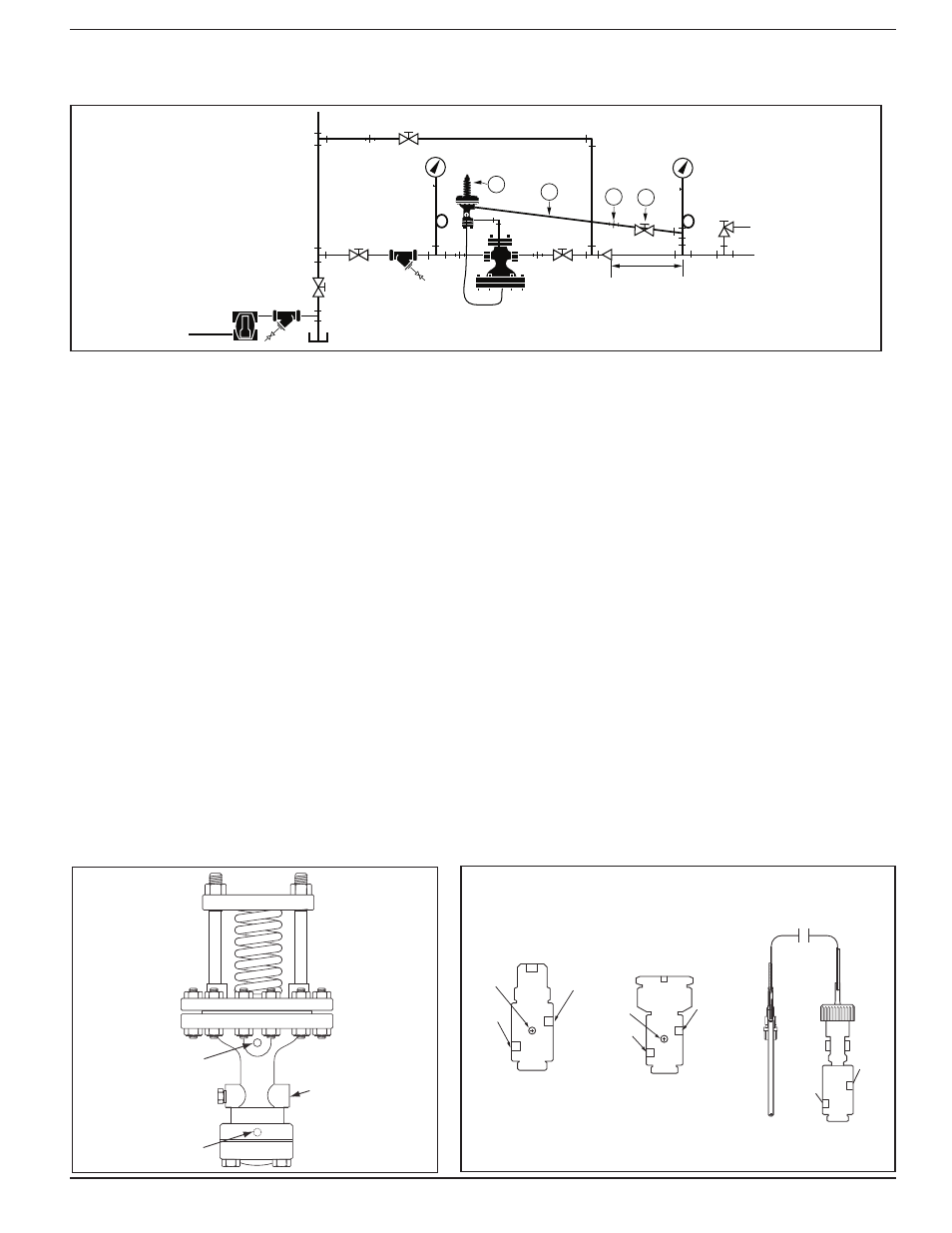

Pilot Installation Detail - For Reference Only

STEP 2 - Mounting Pilot Hardware

A

D

10 Pipe

Diameters

C

B

Applies to All Pilots

Numbers in parentheses refer to items in Kits A or B, pg. 1.

1.

The pilot valve(s) can be installed on either side of the

main valve. The main valve is shipped with the U-

tubing and the bleed orifice installed for left-hand side

mounting of the pilot valve(s). If right-hand side

mounting of the pilot(s) is desired, the U-tubing and

the bleed orifice must be relocated to the opposite

sides of the main valve.

Note: Right-hand side and left-hand side positioning is

determined when the main valve inlet directly faces

the observer.

2.

Make sure the bleed orifice is installed in the 1/8 NPT

tapping on the outlet end of the main valve on the

opposite side from the U-tubing. Remove the 1/8 NPT

pipe plug from the bleed orifice and replace it with a

1/8 NPT x 1/4" (6mm) OD tubing, straight compression

fitting (from the hardware kit #10).

3.

Install the 1/4 NPT x 1-1/2" (38mm) nipple and half of

the union connection (from the hardware kit #4 and

#5) on the inlet end of the main valve.

4.

Use the 1/4 NPT x 4" (101mm) nipple (#3) and the

remaining half of the union connection (from the hard-

ware kit) to mount the first pilot. Mount additional

pilots as required using 1/4" steel pipe nipples.

5.

Install the copper tee fitting (from the hardware kit #6)

in the 1/8 NPT signal tapping on the side of the

last pilot with the tee pointing down.

6.

Install the L-fitting (from the hardware kit #7) in the tapping

at the center of the main valve diaphragm cover.

Note: For steps 7 and 8, trim the length of the copper

tubing as required (see "Tubing Length Chart", page

2) to make a neat installation. Be sure to ream the

tube to the full tube diameter after cutting.

7.

Install the S- or J-copper tubing (from the hardware

kit #2 or #9) from the tee fitting to the bleed orifice.

8.

Install the L- copper tubing (from the hardware kit #1)

from the bottom of the tee fitting to the L-fitting in the

main valve diaphragm cover.

9.

The 1/4" feedback tapping must be connected to the

downstream piping for either a spring or air pressure

pilot:

• Use 1/4 black steel pipe for the feedback line (B)

(not supplied with this kit).

• Install a 1/4 NPT shut off valve (D) and union (C)

in this line to allow service of the pilot while

operating the system on the by-pass line.

• The feedback line must pitch away from the pilot

to avoid erratic operation, excessive fouling and

eliminate water pockets.

When the regulator is used with a heat exchanger,

connect the feedback line (B) to the heat exchanger

shell. A tee fitting can be installed in the heat

exchanger for a vacuum breaker connection.

1/4 NPT

Feedback

Port

1/4 NPT Inlet

on opposite side

1/8 NPT

Signal Port

(#6 Tee Goes

Here)

Identification of SPS Series Spring Pressure Pilot Ports

Identification of Air and Temperature Pilot Ports

Air Pilots

Temperature Pilot

Feedback

Signal

Inlet

Signal

Feedback

Inlet

Signal

Inlet