Troubleshooting pneumatic, Electrical, Maintenance – Bell & Gossett HS 618B Series GT610-IP Electronic-Pneumatic Transducer User Manual

Page 4

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. HS-618B October 2012 Part No. 511134

TROUBLESHOOTING

Pneumatic

1. Check supply pressure. It should be constant 35 psig

(241 kPa) for the 6-30 psig (41-207 kPa) units. 100

psig (690 kPa) is maximum useable supply pressure.

2. Make certain that pressure connections are tight.

3. Check start point and span as previously outlined.

4. Check to see if wire screen is obstructed.

5. Check diaphragms (10) and (11) for rupture and

replace if necessary. See disassembly procedure

under "Maintenance".

6. If disassembly of transducer is necessary, it is recom-

mended it be done in a clean area. Should foreign par-

ticles enter any area of the assembly a malfunction

may occur. Do not attempt to remove magnet housing

subassembly as this will destroy the calibration of the

nozzle and flexure assembly relationship.

7. If the maximum specified output pressure cannot be

obtained, verify the supply pressure using an alternate

gauge. Also, verify the input using a digital multimeter.

Some field calibrators may not be capable of supplying

sufficient current to the higher voltage units.

Electrical

1. Is it proper 4-20 mA DC or 1-9 VDC range?

2. Check to see that input signals leads are connected to

proper terminals. (Refer to Electrical Connection section).

3. Make certain there are no loose wires at terminal

connections.

4. Check internal resistance by connecting ohmmeter to

terminal block. In making any resistance tests, the input

signal wires from controller must be disconnected.

Do not change setting of range adjust potentiometer

on printed circuit board while making this test.

Input Range

Nominal Input Impedance

4-20 mA DC

225 ohms

1-9 VDC

535 ohms

MAINTENANCE

Under normal conditions, no maintenance should be

required. If disassembly is necessary, refer to "Pneumatic

Troubleshooting" section. It is important that clean, dry air

be supplied to the unit at all times.

Periodically inspect the diaphragm (11) and diaphragm

assembly (10) to see if the diaphragms show any signs of

wear. To inspect the diaphragms, remove the four 10-32

fillister head screws. Then remove the pilot body sub-

assembly (6) and spacer (5). To check for any foreign

matter which may have accumulated around the nozzle

plug, remove cap nut (7), O-ring (8) and plug spring (9).

Exercise caution when inspecting the nozzle plug to avoid

damaging the seating surface on the plug or in the pilot

body. When reassembling the booster relay be sure to

properly orient the bleed hole.

13

2

1

13

14

3

3

5

6

7

4

12

11

10

9

8

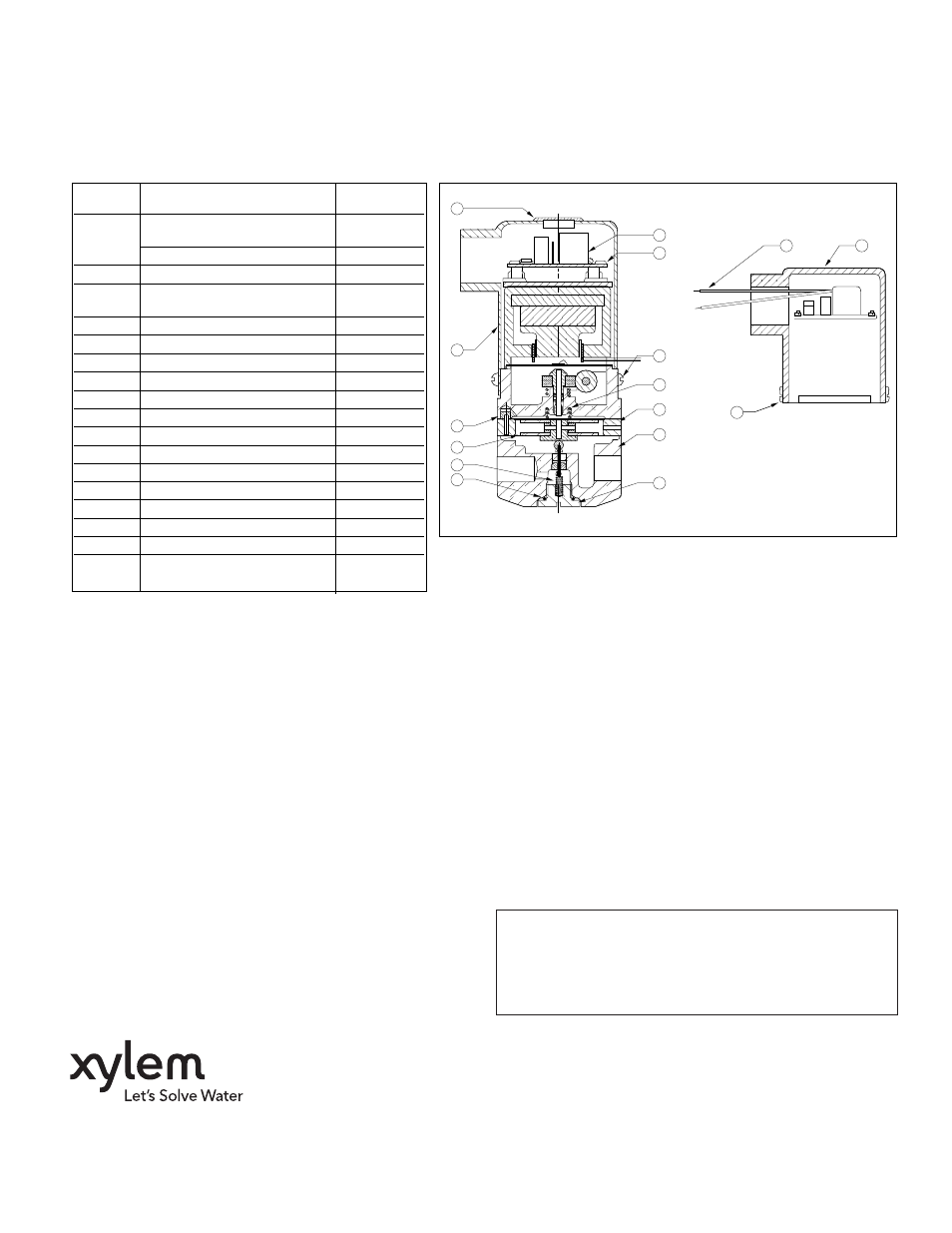

Item

Description

Qty.

No.

Required

1

Printed Circuit Board

1

4-20/10-50 MA DC

0-5/1-9 VDC

1

2

PC Board Support Post

4

3

Cover Mounting Screws

4

PHMS #6-32 x 1/4" long

4

Bias Spring

1

5

Spacer (exhaust)

1

6

Pilot Body Subassembly

1

7

Cap Nut

1

8 (1)

Cap Nut O-ring

1

9 (1)

Pilot Spring

1

10 (1)

Diaphragm Assembly

1

11 (1)

Upper Diaphragm

1

12

Cover

1

13

Cover Grommet

1

14

Lead Wire (18" (457mm)

1

Long - 18 GA) Pos.-Red

Negative - Black

1

15

Mounting Bracket

1

(not shown)

WARNING: Manufactured with (1, 1, 1-Trichloroethane),

a substance which harms public health and

environment by destroying ozone in the upper

atmosphere.