Operation – Bell & Gossett HS 618B Series GT610-IP Electronic-Pneumatic Transducer User Manual

Page 2

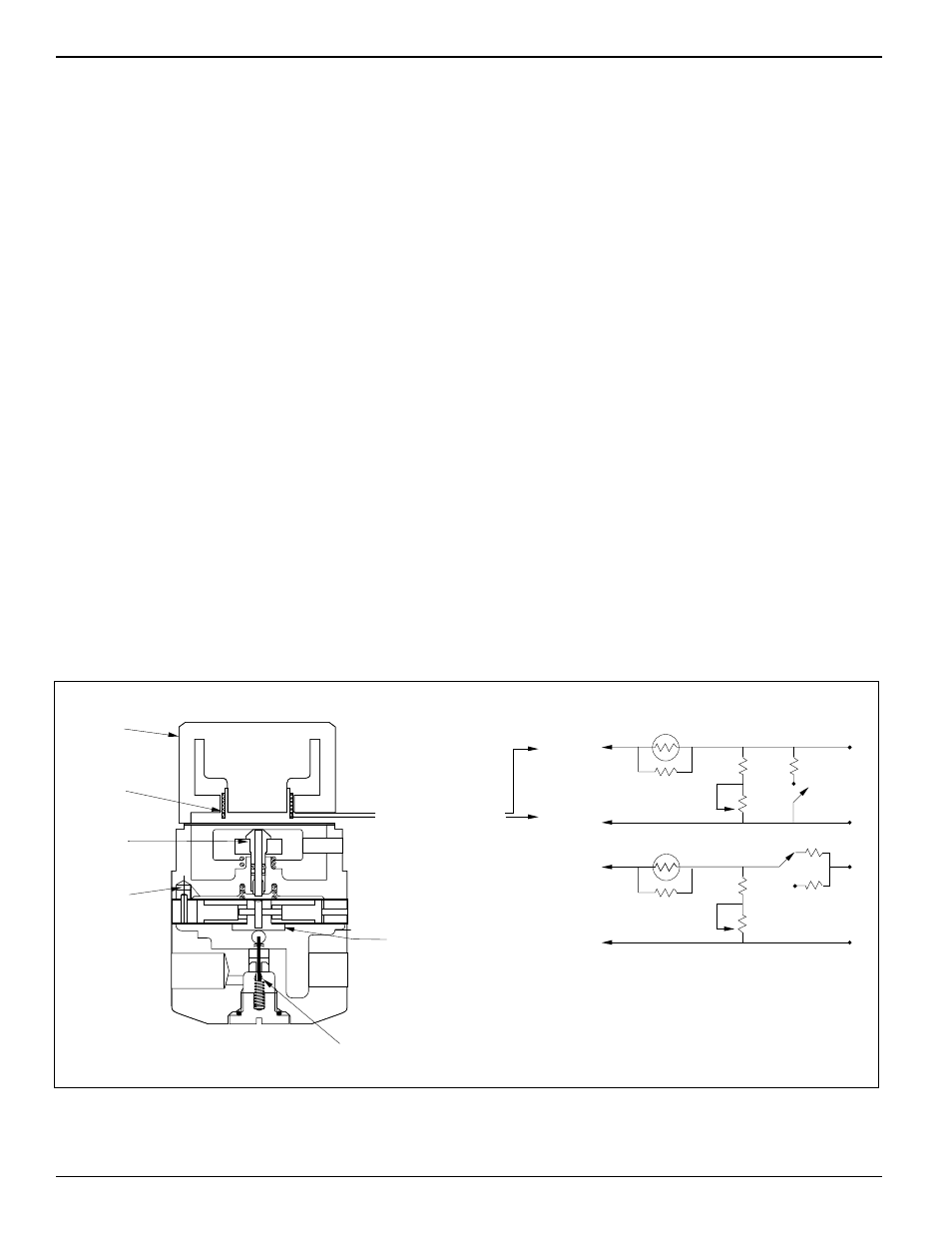

In the direct acting mode, an increase in the input signal

causes the coil to move away from the magnet which moves

the flexure assembly toward the nozzle. This reduces the

flow through the nozzle increasing the back pressure in the

top chamber of the booster. The increased pressure in the

booster causes the diaphragm assembly to move down-

ward, opening the pilot valve and increasing the output

pressure. The output pressure will continue to increase

until it is equal to the nozzle back pressure and the forces

on the diaphragm assembly are balanced.

A decrease in the input signal allows the coil to move

toward the magnet which moves the flexure assembly

away from the nozzle. This allows the flow through the

nozzle to increase which reduces the back pressure in the

top of the booster. Since the output pressure is greater than

the nozzle back pressure, there is a net upward force on the

diaphragm assembly which causes it to move upward

allowing the pilot valve to close and opening the relief port.

The excess output pressure is vented to atmosphere

through the relief port until equilibrium is established.

In the reverse acting mode, an increase in the input sig-

nal causes the coil to move toward the magnet instead of

away from it since the direction of the current through the

coil is reversed. An increasing signal, therefore, causes a

proportionally decreasing output.

OPERATION

Inputs:

4-20 or 10-50 mA DC

0-5 or 1-9 VDC

Outputs:

GT610 = 6-30 Psig (41-207 kPa)

MAGNET

NOZZLE

COIL

FIXED

ORIFICE

ELECTRICAL INPUT

EXTERNAL

ZERO ADJUST

OUTPUT AIR SIGNAL

PILOT VALVE

EXHAUST (TYPICALLY

ATMOSPHERIC AIR)

DIAPHRAM

ASSEMBLY

FILTERED

AIR SUPPLY

(20 PSI

REQUIRED

+

-

+

-

T1

R5

COIL

COIL

TL

R5

R4

10-50

R2

mA

mA

4--20

0-5V

1-9V

H2

R1

H2

R3

R4

R3