Caution, Maintenance, Installation complete – Bell & Gossett HS 232C Series I In-line Float and Thermostatic Steam Traps User Manual

Page 7

7

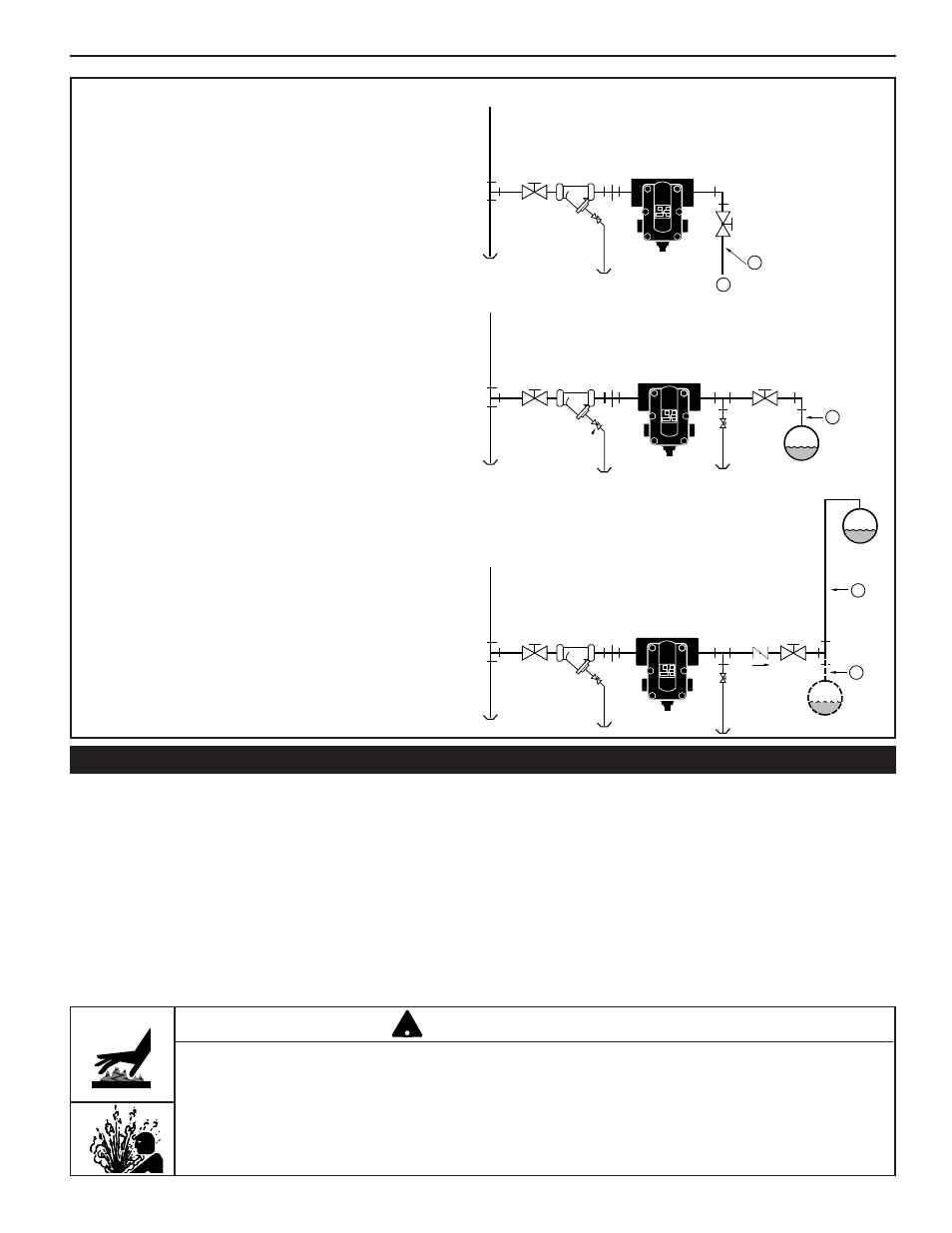

15. Depending on your application, complete one

of the following steps:

a. Connect the return line (M) to a drain (U)

OR

b. Add a gravity return line (V)

OR

c. Add a pressurized return (W) or a return line

above the trap discharge (X).

M

U

V

X

W

INSTALLATION COMPLETE

MAINTENANCE

When checked regularly and properly maintained, the

Series I Float and Thermostatic Traps will provide opti-

mum performance and long life.

SCHEDULE:

• Initially, every 2-3 days after start-up until

system is clean.

• Every 6 months thereafter.

PROCEDURE:

• To prevent serious burns, the internal pressure of the trap must be 0 psi (0 bar)

before servicing.

• To prevent serious personal injury from steam pipe blow down, connect a temporary

pipe between the steam pipe opening and a drain, or stand at least 100 ft. (30m) from

the front of the pipe opening.

Failure to follow this caution will cause personal injury.

!

CAUTION

1.Inspect joints for leaks. Stop all leaks by tightening

bolts and replacing gaskets, if necessary.

2.Clean strainers by opening the blow down valve and

allowing full steam pressure to flow out for (2) two

minutes. Then, close the valve.

3.Test traps by following the “Troubleshooting”

procedure.