Opera tion and maintenance, Inlet basket strainer maintenance, Special piping arrangements for low returns (if – Bell & Gossett DN0153D HS Vacuum Heating Units Series HV User Manual

Page 6

OPERA

TION AND MAINTENANCE

Operators must be familiar with all sections of this manual to

understand the operation of the unit.

Hot water, steam and electricity can be hazardous.

LUBRICATION

The only pump bearing requiring lubrication is the ball bearing

in the motor support just below the flexible coupling. It has a

reservoir, which is filled with moisture resistant high tempera-

ture grease.

Remove pipe plug in motor support and add approximately 3

ounces of Shell Alvania RL 2 grease (or equivalent) from once

a year (normal) to twice a year for extremely hot conditions. Do

not use ordinary grease.

NOTICE / AUTO RESTART

Single phase motors will restart automatically after thermal

overload protector trips.

Overload thermal relays in starters must be reset manually.

A properly installed unit should function unattended for long

periods of time. Periodic checks to assure proper operation

are highly recommended. Refer to trouble shooting section

when necessary.

A variety of control options are available and are furnished in

accordance with user specifications. Refer to wiring diagrams

(when furnished) to determine control switch settings.

The inlet strainer (when furnished) in intended to protect the

pump and system. Periodic cleaning should be included in the

maintenance schedule. Check frequently in new systems.

GAGE GLASS MAINTENANCE

(Vented Systems)

Clean gage glass as required using commercial glass cleaner.

Dilute muratic acid may be used if required (observe handling

precautions). Never clean gage glass with wire brushes,

scrapers or harsh abrasives.

Do not reuse gage glass or packings or seals.

Immediately replace glass which is broken, cracked, chipped,

scratched or otherwise damaged. Inspect periodically with a

bright concentrated light. Anything which glistens and catches

the fingernail or any star-shaped or crescent-shaped mark

which glistens is cause for replacement. Any gage glass which

appears cloudy or roughened and will not respond to cleaning

procedures should be replaced.

When replacing gage glass, use new packings specified for

this use. Install glass with sufficient end clearance for expan-

sion (keep glass to metal clearance at each end) and tighten

nuts just enough to avoid leakage (do not over tighten).

Condensate enters the screen from the bottom and flows out-

ward from the inside. Foreign matter intercepted by the screen

may drop into the large dirt pocket in the lower portion of the

strainer body; however, grease, oil, gasket material and other

foreign substances present in all heating systems are likely to

stick and clog the strainer screen. For this reason it may be

necessary to clean the strainer several times a week during

the first few months of operation.

To clean strainer proceed as follows: (1) open disconnect

switch(es), (2) close return line gate valve, (3) remove drain

plug, (4) remove cap screws, cover and screen, (5) clean

screen thoroughly, (6) flush strainer body and dirt pocket, (7)

inspect gasket, (8) reassemble.

While the pump is shut down inspect and clean the multi-jet

nozzles as follows: (1) drain receiver below nozzle level by

removing drain plug, (2) remove discharge manifold cover

plate and multi-jet nozzle, (3) clean nozzle, (4) inspect gasket

and reassemble, (5) reprime pump to half way level in gauge

glass, (6) close switches, (7) open return line gate valve slowly.

INLET BASKET STRAINER MAINTENANCE

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

CAUTION:

SUBSEQUENT DAMAGE

A unit showing symptoms of possible problems

(overflow, noise, leaks, vibrations, continual operation, etc.)

must be corrected immediately. Failure to follow these

instructions may result in full liability for subsequent injury

or property damage.

SAFETY INSTRUCTIONS

SEE COVER OF THIS MANUAL

WARNING:

EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during

leak test. Do not plug overflow. Do not restrict vent opening

to atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.

6

VACUUM GAUGE TAPPING

VACUUM BREAKER TAPPING

CAPSCREWS

COVER

GASKET

SCREEN

STRAINER BODY

DRAIN PLUG

(ON REAR OF STRAINER)

THERMOMETER

(ON FRONT OF STRAINER)

FIG. 11

5

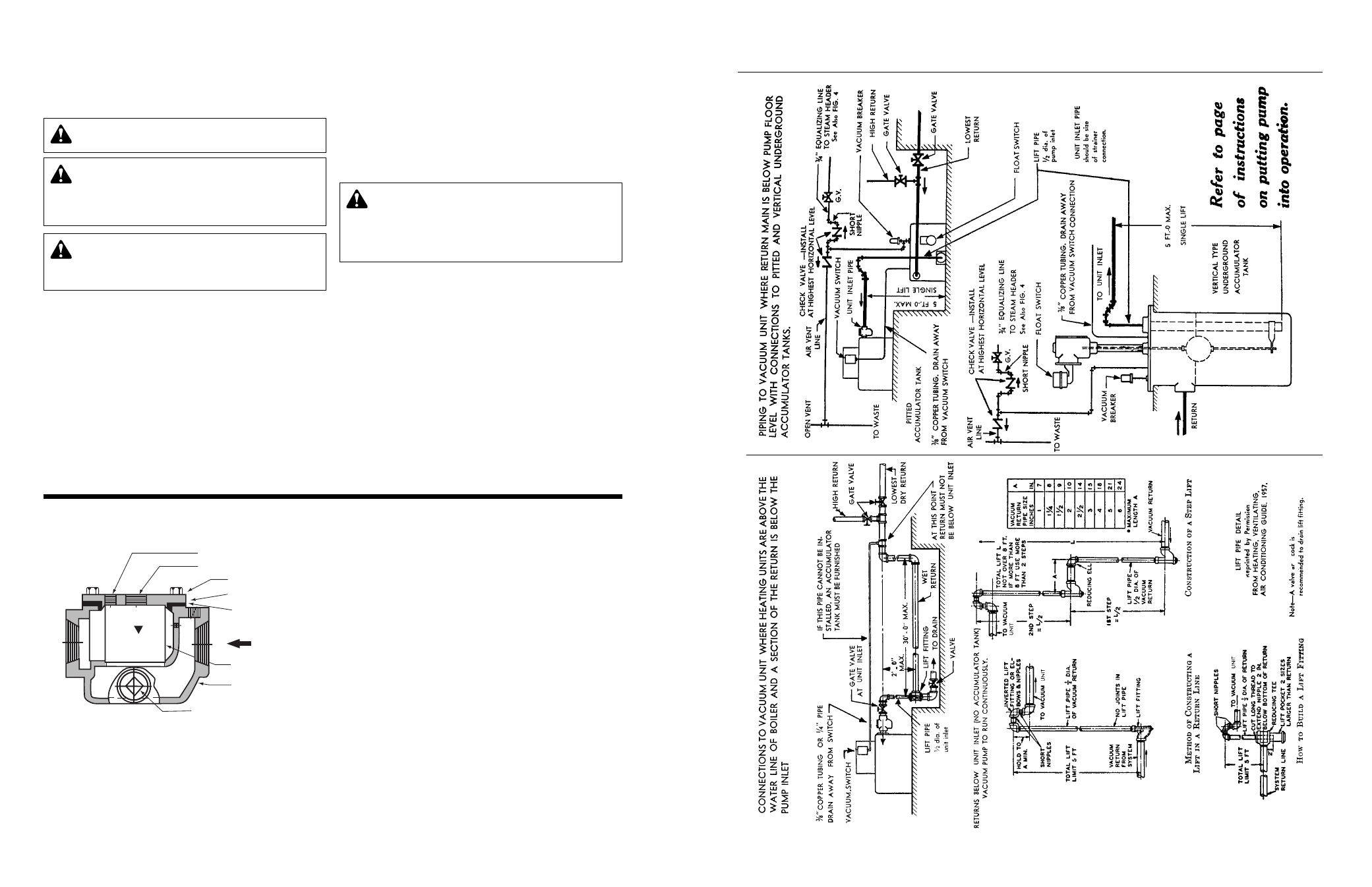

SPECIAL PIPING ARRANGEMENTS FOR LOW RETURNS

(IF

LIFT EXCEEDS 5 FEET, A MECHANICAL LIFT IS RECOMMENDED)

FIG. 5

FIG. 7

FIG. 6

FIG. 9

FIG. 10

FIG. 8