Putting the unit into ser vice, Selector or v acuum switch settings – Bell & Gossett DN0153D HS Vacuum Heating Units Series HV User Manual

Page 4

4

Install gate valve in return line for testing pump shut off vacu-

um, closing off hot returns when cleaning strainer, etc. Do not

install check valve in return line. Avoid elbow or tee located

closer to strainer inlet than 10 times inlet diameter. If unavoid-

able relocate vacuum switches to top of nearest “dry” point on

return main unless a portion of return is below pump inlet an

accumulation tank is recommended. Accumulator tank may

not be necessary if low length of return is not lower than 24"

below pump inlet or longer than 30'. See TYPICAL PIPING-

LOW RETURNS. High pressure steam traps should empty into

uninsulated flash tank where condensate will cool before

entering unit.

DISCHARGE LINE

Install union, check valve, steam cock and gate valve at unit in

each discharge line. Steam cock to be adjusted to cause

pump to operate at specified pressure. If discharge line is

more than 100' long, install pipe 1 or 2 times larger than dis-

charge valve tapping.

ELECTRICAL WIRING &

CONTROLS

Connect power wiring per NEC. Recheck nameplate vs. speci

-

fications and conditions. All single phase motors have internal

thermal protection.

Three phase motors must use starters with properly sized

overload relays. Overload relays furnished are designed for

manual reset.

WARNING:

HIGH VOLTAGE ELECTRICITY

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

POSITION

WHEN USED

OPERATION

“Vacuum and Float” or “Fl-Vac”

Normal position

Pumps operate on either low

vacuum or high condensate

“Float Only” or “Float”

Sometimes used for night and week-end service. This

Pump starts and stops on

setting not recommended for use with lift fitting.

Condensate level change

“Continuous” or “Hand”

Testing and for unusually high

Continuous

lift conditions in return lines.

“Off” (Duplex Units only)

Adjust controls, inspect pump

Prevent operation of motor

PUTTING THE UNIT INTO SER

VICE

1.

Assure that the unit is piped in accordance with instructions.

2. Isolate tank before performing any system leak test. Do

not pressurize the tank as part of the leak test. Failure to

do this can result in serious injury or death.

3. Check floats for free operation.

4. Check power leads in accordance with wiring diagram

enclosed in control cabinet (when furnished).

5. Install drain plugs.

6. Fill receiver (upper compartment on Series HV) half full of

water to prime pump(s) and prevent possible damage to

pump seals. Avoid freezing conditions after unit receiver

has been filled.

7. Check for proper rotation of all three phase motors.

Rotation must be clockwise looking down on the motor as

indicated by directional arrow on pump casting. If pump

runs backwards, interchange two wires (3 phase only).

8. Throttle plug cock in discharge line until pressure at pump

(while pump is discharging) approaches pump rated pres-

sure. Tighten plug nut to secure adjustment.

9. Remove start-up label (below) from panel (if applicable)

after complying with instructions.

10. If possible, observe operation thru several cycles using

selector or vacuum switch settings as noted below.

SELECTOR OR V

ACUUM SWITCH SETTINGS

The vacuum switches are adjusted and tested at the factory

for proper operation. The vacuum switch on a single unit and

the lead switch of a duplex unit is set to close at 3" Hg vacu-

um and open at 8". The lag switch of a duplex unit is set to

close at 2" and open at 8".

These settings are suitable for all normal installations including

those having an accumulator tank or lift fitting. If settings must

be readjusted refer to manufacturer’s instructions.

WARNING:

HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

CAUTION:

DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR.

Inspect pump seal regularly for leaks. Replace as required.

Failure to follow these instructions could result in injury or

property damage.

CAUTION:

DO NOT REVERSE

Reverse operation can cause extensive damage to

pumps. Jog the motor to test for direction of rotation.

Failure to follow these instructions could result in injury or

property damage.

ELECTRICIAN/INSTALLER/OPERATOR

REMOVE AND DESTROY THIS TAG AFTER —

1. ASSURING THAT ALL PUMPS ROTATE CLOCKWISE PER ARROWS

CAST ON VOLUTES. (JOG PUMP MOMENTARILY TO TEST – INTER-

CHANGE ANY TWO MOTOR POWER WIRES TO REVERSE 3PH

MOTORS.)

2. ASSURING THAT SHIPPING LOCKS HAVE BEEN REMOVED FROM ALL

FLOAT SWITCHES.

WARNING:

EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during

leak test. Do not plug overflow. Do not restrict vent opening

to atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.

3

Receivers are non-code cast iron.

PRELIMINARY INSPECTION

Assure that there is no shipping damage.

Assure that nameplate ratings agree with job specifications

and actual conditions.

HANDLING

Use care in installing unit.

LOCATION

Place unit for easy access to all parts. Allow adequate space

for servicing. Check ambient conditions.

NOTICE / TEMPERATURE LIMITS

Motors are designed to operate in 104

°F max. ambient.

Insulate or ventilate as required.

PIPING (GENERAL)

Pipe the unit per the Elementary Piping Diagram. Locate and

support piping so as to not load the discharge valve.

PIPING

(Vent)

Install a vent pipe to atmosphere. Pipe to be size of vent port

on unit. Do not restrict or reduce vent opening or exceed 20

feet vertical height unless an overflow connection is provided.

PRIMING PORT

Provide a priming port as shown on piping diagram.

FLOAT SWITCHES

Floats are locked in place to prevent damage during shipment.

Remove shipping locks. Check factory settings. Floats are

adjustable for various levels of operation.

See page 7 for detailed instructions.

EQUALIZING LINE

An equalizing line must be installed with all Series HV units.

This line must be installed to prevent formation of a vacuum

on the radiation side of the system when steam stops flowing

in the mains. This vacuum may be higher than return line vac-

uum, which would prevent condensate from flowing back to

the pump. To correct this in an unzoned system, install equal-

izer line as shown in the piping diagram. To correct this in a

zoned system, install equalizer line for each zoned section or

install a vacuum breaker on supply line on radiation side of

each zone control valve.

PIPING

(Returns)

Gravity return lines from system must be properly pitched

down to unit inlet. Returns must also be trapped to prevent

steam entry into the unit. An inlet basket strainer is

recommended.

CAUTION:

UNIT LIFTING EYE

Use unit lifting eyes only to lift unit as shipped from

factory. Unit must be empty and disconnected from pipes,

anchors and other restraints. Use proper rigging pro-

cedures. Failure to follow these instructions could result in

injury or property damage.

CAUTION:

NOT A CHEMICAL PUMP

Inject boiler feed compounds from chemical feed

tank into boiler feed piping – never into condensate tank.

Failure to follow these instructions could result in injury or

property damage.

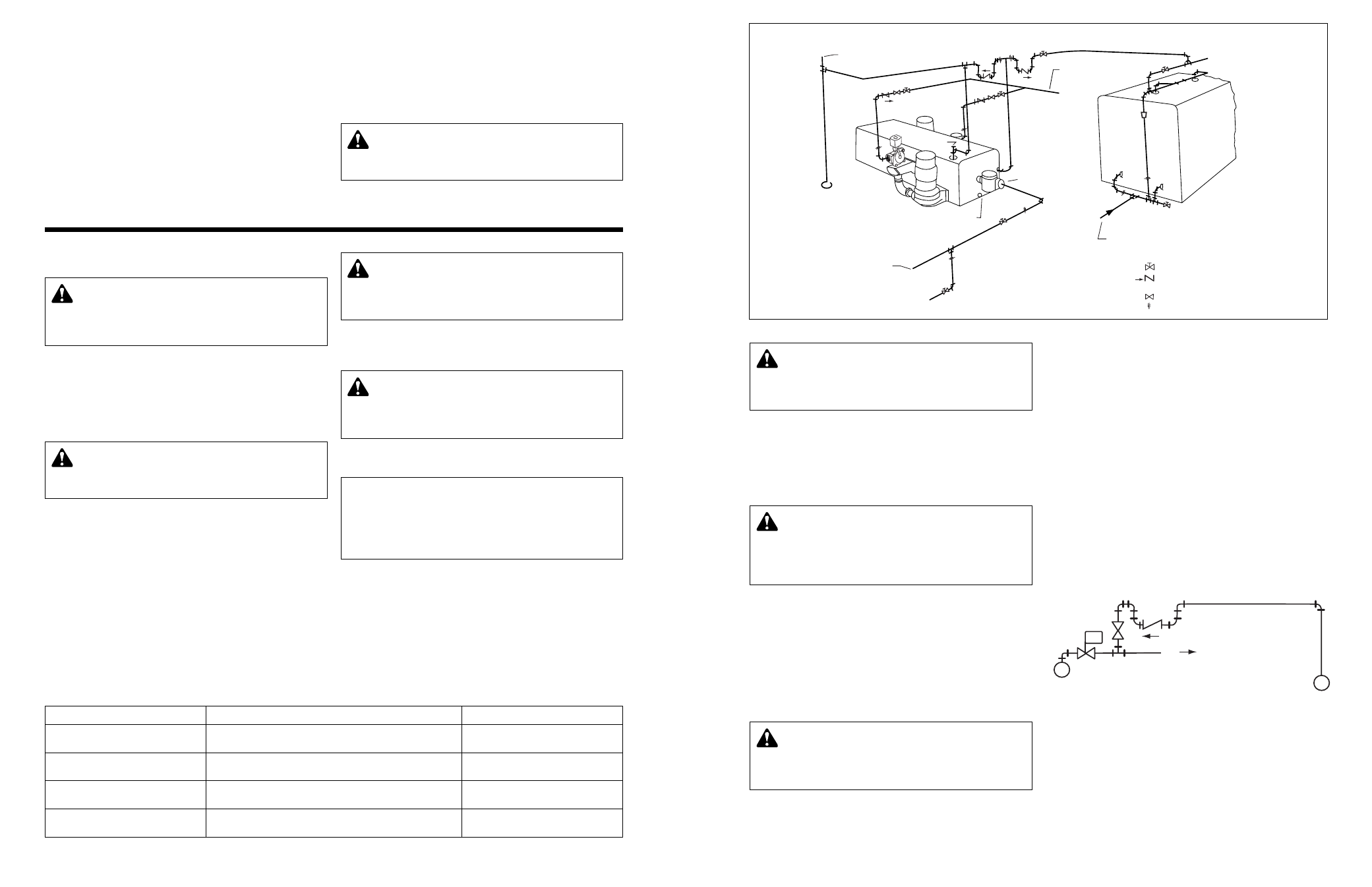

TO BOILER

FEED

SYSTEM

REDUCER

STRAINER

SERIES VLR DUPLEX

PIPING DIAGRAM

DRAIN

DRAIN

DRAIN

DV

PRIMING

OPENING

EQUALIZING LINE —

3

/

4

"

BOILER

FROM BOILER

FEED SYSTEM

— GATE VALVE

— DISCHARGE VALVE

DV

— STEAM OR PLUG COCK

— UNION

— CHECK VALVE

OPEN VENT ABOVE

BOILER WATER LINE

RETURN FROM

HEATING SYSTEM

EQUALIZING CONNECTIONS FOR ZONED SYSTEMS

ZONE CONTROL

VALVE

STEAM MAIN

M

TO ZONE

RETURN MAIN

FIG. 4

FIG. 3

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during

leak test. Do not plug overflow. Do not restrict vent opening

to atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.