Hoffman specialty, Dealer ser vice – Bell & Gossett DN0153D HS Vacuum Heating Units Series HV User Manual

Page 10

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. DN0153D February 2013

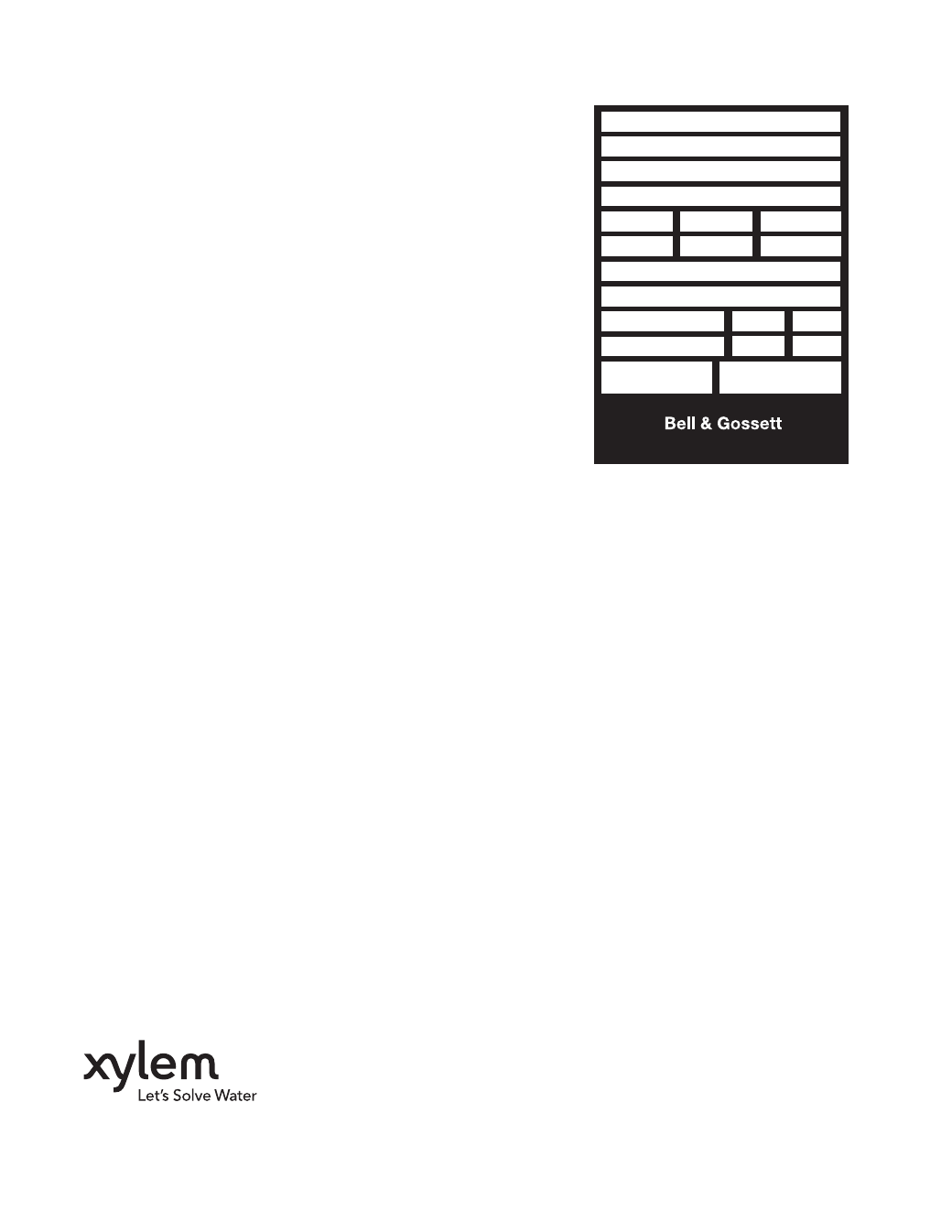

DEALER SER

VICE

If trouble occurs that cannot be rectified, contact your local

B&G representative. He will need the following information in

order to give you assistance.

1. Complete nameplate data of pump and motor.

SEE RATING NAMEPLATE at right.

2. Vacuum readings.

3. Ampere draw of the motor.

4. A sketch of system piping.

Morton Grove, Illinois 60053

TM

SERIES HV

MODEL

SERIAL

GPM

PSI

PUMP

CFM

IN HG.

PUMP

DWGS

POWER V.

PH.

HZ 60

CONTROL V.

PH. 1

HZ 60

TOTAL

LARGEST MOTOR

F.L. AMP

F.L. AMP

DN0016

HOFFMAN SPECIALTY

®

PUMP MAKES NOISE

1.

The pump is working against a lower pressure than designed for.

While pump is discharging, adjust square headed steam cock in

discharge line until pressure at pump approaches pump rated

pressure. Secure adjustment of steam cock by tightening lock

nut.

2. Excessive condensate temperature. Correct system conditions.

3. Magnetic hum or bearing noise in motor. Consult motor manufac-

turer’s authorized service station nearest pump location.

4. Starter chatters. Trouble is caused by low line voltage, poor con-

nections, defective starter coil, or burned contacts.

5. Pump is running backward.

6. Water hammer when discharge valve closes:

(1) Adjust steam cock to reduce discharge velocity or

(2) Install surge chamber on boiler side of discharge check valve or

(3) Install additional check valve near boiler or

(4) Install discharge piping 1 or 2 sizes larger.

THE

SYSTEM IS NOISY

1.

Banging in the steam mains is usually caused by “imploding” in

condensate lying in low points in lines. These pockets can be

eliminated by “dripping” low points, properly supporting the pipe,

or by increasing the pitch of the lines.

2. Improper dripping of the steam mains and risers. Where there is a

rise in the steam main, or where it branches off into a riser, a drip

trap must be installed to the drain line.

3. The piping is too small to drain properly.

4. A defective trap is holding condensate in radiation.

5. A priming boiler is permitting a carry-over of water with the steam.

A priming boiler is caused by:

(1) Oil or other foreign matter. Clean boiler thoroughly.

(2) A reduction of the steam liberating area due to too high a

water level in the boiler. Reduce water line.

(3) Overloading. Reduce firing rate.

(4) Undersized steam outlet area, resulting in velocities in excess

of 15 to 25 ft. per second.