Hurling chamber floa t switch adjustment, Control p anel selector switch settings – Bell & Gossett DN0136C Domestic Pump Vacuum Heating Units Series VCL User Manual

Page 8

8

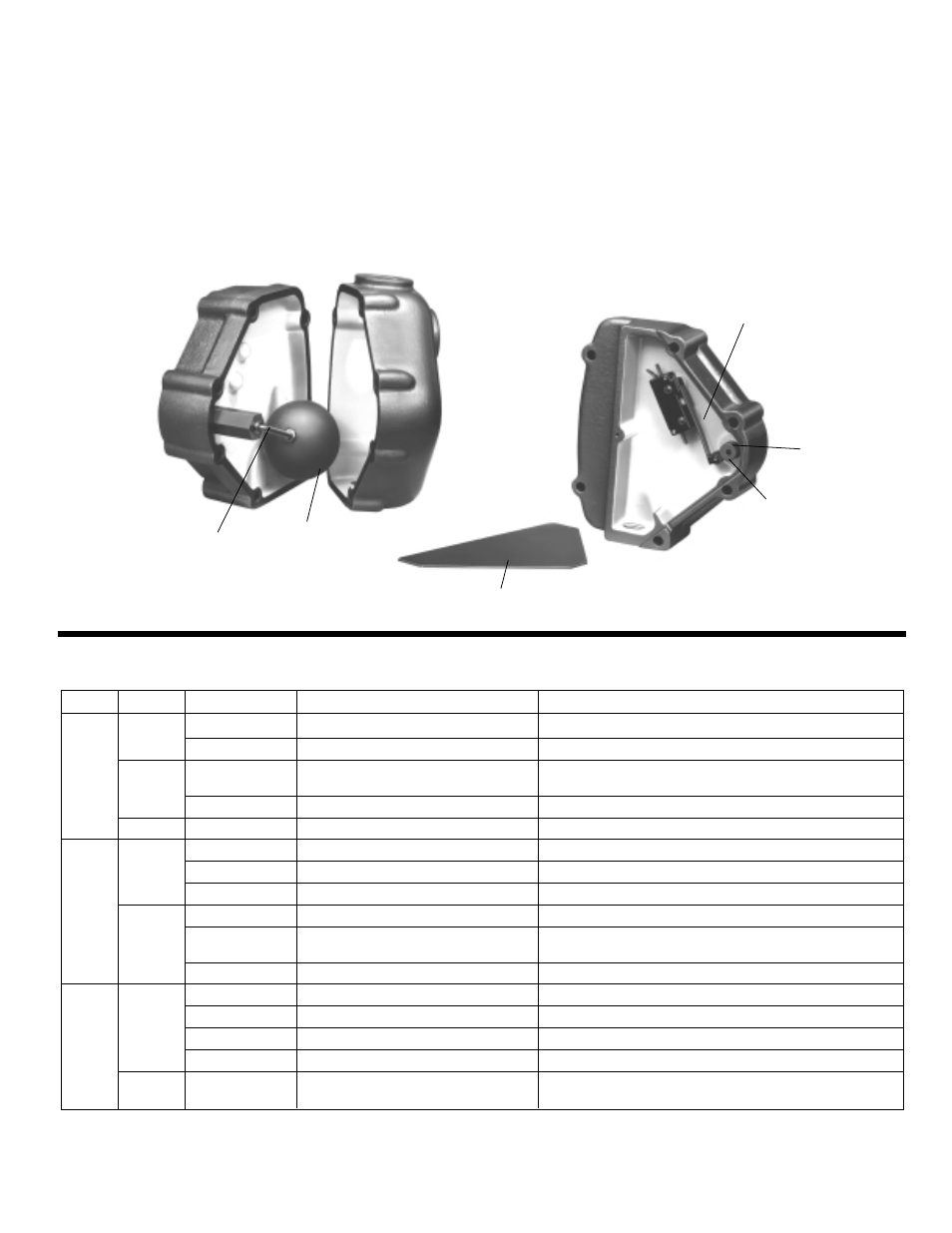

The switch which controls the hurling water makeup valve is

located inside the float housing near the vacuum unit overflow.

The switch is under a triangular coverplate which is retained by

one #6 screw (loosen bolts retaining the cover edges only if

necessary). The actuating cam can be rotated for testing by

using a screwdriver in the slot provided.

Adjust the switch location so that the switch snaps at approx-

imately mid-range of the cam travel. The #6 screw near the

cam goes thru a slot in the switch mounting plate. Loosen this

screw (and farthermost screw thru the switch) to permit adjust-

ment of the switching position. Tighten screws and recheck

operation after making any adjustment.

The cam should be positioned on the shaft for maximum

switch roller movement in operation. The cam is retained by a

socket set screw.

Replacement seal tube assemblies are available in case of

leakage around the float pivot shaft.

HURLING CHAMBER FLOA

T SWITCH ADJUSTMENT

Pump

Model

Position

Purpose

Operation

VCD 2

Automatic

Normal.

Pump starts on high condensate level, stops on low.

Off

Adjust controls, inspect pump.

Prevent operation of motor. Caution: See footnote 1.

VCD 3

Lead

Set one switch to “lead”, other to “lag”.

Lead pump starts first on high condensate level, lag pump

and

Lag

Reverse periodically.

runs in emergency.

VCD4

Off

Adjust controls, inspect pump.

Prevent operation of motor. Caution: See footnote 1.

Any

Hand

Test rotation and/or pressure.

Caution – Pump may run dry and damage seal.

VCD 2

Automatic

Normal.

Pump starts on low vacuum, stops on high vacuum.

and

Off

Sometimes right or week-end.

2

Unit operates as a simple condensation pump.

VCD 3

Continuous

Testing or high lifts in returns.

Pump operates continuously.

Off

Sometimes right or week-end.

2

Unit operates as a condensation pump.

Lead

Set one switch to “lead”, other to “lag”.

Lead pump starts first on low vacuum, lag pump also runs on

VCD 4

Lag

Reverse periodically.

start up or with large system leaks.

Continuous

Testing or high lifts in returns.

Air pump runs continuously.

VCD 2

Float & Vacuum

Normal.

Pump starts on high condensate level or low vacuum.

4

Float Only

Sometimes night or week-end.

2

Air pump responds only to condensate level change.

VCD 3

Continuous

Testing or high lifts in returns.

Pump operates continuously.

VCD4

Off

Adjust controls, inspect pump.

Prevent operation of motor. Caution: See footnote 1.

VCD 4

No. 1 pump leads

Set one switch to “lead”, other to “lag”.

Lead pump starts first on float and/or vacuum depending on

Only

No. 2 pump leads

Reverse periodically.

setting of other vacuum pump selector switch.

CONTROL P

ANEL SELECTOR SWITCH SETTINGS

W

A

TER

AIR

AIR WITH

ACCUMULA

TOR

3

1

Caution – this is not a disconnect switch for power supply.

2

Not recommended for systems with lift fittings.

3

Air pumps respond to conditions in accumulator tank.

4

Duplex air pump runs on abnormally high rate of condensate flow, and on start-up.

FLOAT ROD

MICRO SWITCH

CAM

FLOAT BALL

CAM SET

SCREW

INSPECTION PLATE