Bell & Gossett DN0136C Domestic Pump Vacuum Heating Units Series VCL User Manual

Page 3

PIPING

(Returns)

Gravity r

eturn lines from system must be properly pitched down

to unit inlet. Returns must also be trapped to prevent steam

entry into the unit. An inlet basket strainer is recommended.

SUCTION PIPING

Suction piping between the condensate r

eceiver and the

vacuum producer should be at least as large as the inlet to the

vacuum producer.

PIPING

(Vent)

Install a vent pipe to atmospher

e. Pipe to be size of vent port

on unit. Do not restrict or reduce vent opening or exceed 20

feet vertical height unless an overflow connection is provided.

PIPING

(Overflow)

Pipe overflow port to drain using an overflow loop when con

-

densate temp will exceed 200ºF. (93°C).

The overflow port on the hurling chamber acts as the overflow

for both the vacuum producer and condensate return units.

Pipe to a suitable drain.

Series VCL units have a high level (overflow control) float

switch to start the vacuum pumps when the lower receiver is at

the “full” level. The vacuum pumps will siphon condensate from

the receiver into the hurling chamber.

Excess condensate will then overflow out of the hurling cham-

ber to drain.

FLOA

T SWITCHES & MECHANICAL ALTERNATORS

Floats ar

e locked in place to prevent damage during shipment.

Remove shipping locks. Check factory settings. Floats and

mechanical alternators are adjustable for various levels of oper-

ation. The lead pump should start with tank

3

/

4

full and shut off

at 2" or more above pump inlet. Lag pump should start before

the tank overflows. Settings should avoid “short cycling” of the

pump.

Vacuum switch adjustment is explained on the following page.

An electric alternator (when furnished) must operate off the

lead vacuum switch.

ELECTRICAL WIRING & CONTROLS

Connect power wiring per the National Electrical Code.

Recheck nameplate vs specifications and conditions. All single

phase motors have internal thermal protection.

Three phase motors must use starters with properly sized over-

load relays. Overload relays furnished are designed for manual

reset.

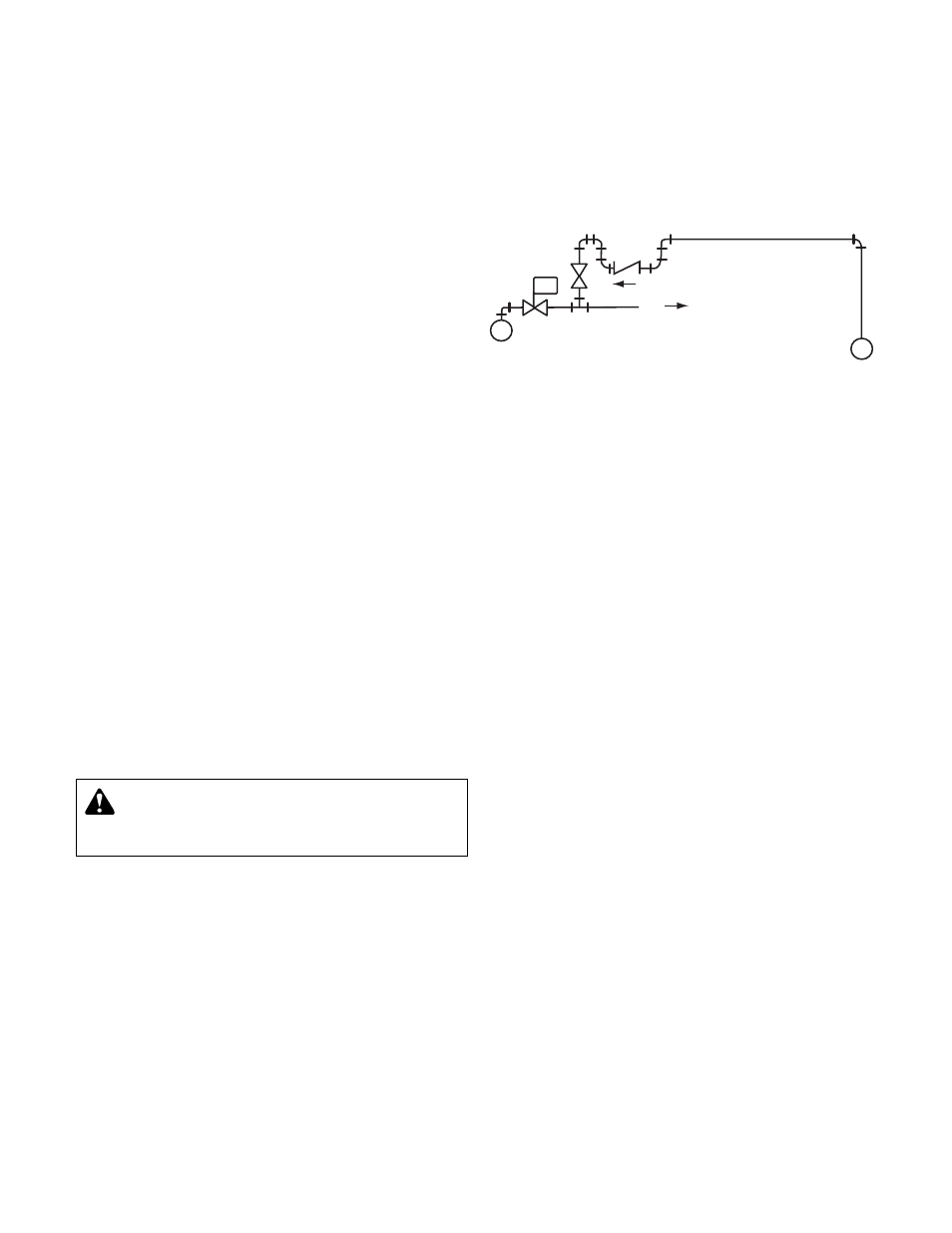

EQUALIZING LINE

A vacuum may be formed on radiation side of system when

steam stops flowing in mains. This vacuum may be higher than

return line vacuum, which would prevent condensate from

flowing back to pump. To correct this in an unzoned system,

install equalizer line as shown. To correct this in a zoned sys-

tem, install equalizer line for each zoned section or install a

vacuum breaker on supply line on radiation side of each zone

valve.

ACCUMULA

TOR TANK

An accumulator tank may be used to facilitate lifting conden

-

sate. The accumulator tank will be fitted with a float switch to

start the vacuum pump as accumulator fills. The vacuum pump

will then siphon condensate into the condensate receiver.

The vacuum sensor line in an accumulator tank system must

sense the vacuum in the accumulator tank as shown on the low

return piping diagrams. (Figure 9, page 5.)

3

ZONE CONTROL

VALVE

STEAM MAIN

M

TO ZONE

RETURN MAIN

W

ARNING: HIGH VOLTAGE ELECTRICITY

Disconnect and lock out power befor

e connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

FIG. 2 EQUALIZING CONNECTIONS FOR ZONED SYSTEMS