Sequence of opera tion – Bell & Gossett DN0136C Domestic Pump Vacuum Heating Units Series VCL User Manual

Page 4

SEQUENCE OF OPERA

TION

Ther

e are two separate and independent cycles of operation

in the VCD design – one of air evacuation and the other for

condensate return. This is accomplished by completely sep-

arating the air pumps from the condensate storage receiver

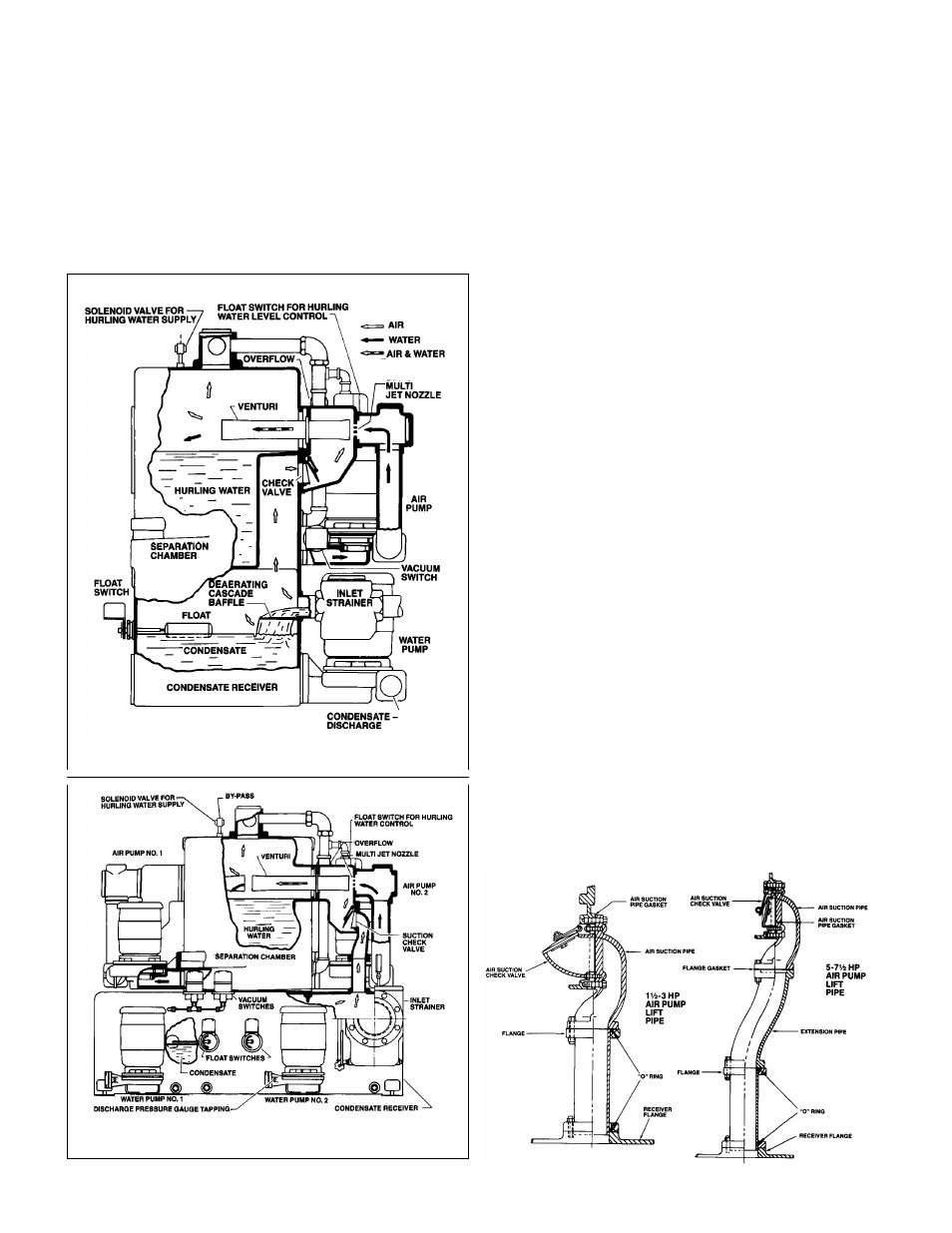

and water pumps. Fig 3 below illustrates a single, two com-

partment receiver, divided horizontally, where the air pumps

operate from the upper compartment or separation chamber

while the water pumps operate from the lower compartment

or condensate receiver. The unit below is similar except that

the air pump separation chamber and condensate receiver are

separate units, connected as shown in Figure 4. The operation

for both types of construction is identical.

AIR EV

ACUATION CYCLE

The independent air evacuation cycle begins when the vacuum

switch, responding to system requirements, starts the centrifu-

gal “air” pump. This pump circulates “hurling” water from the

separation chamber through the multi-jet nozzle, venturi and

returns it to the separation chamber. The water, forced at high

velocity across the gap between nozzle and venturi, entrains air

and gases in multiple jet streams, creating a smooth, steady

vacuum in the condensate receiver and system. The mixture is

discharged through the venturi into the separation chamber

where the air and gases separate from the “hurling” water and

are vented. When the desired vacuum has been produced in

the system, the vacuum switch stops the pump, and the check

valve at air inlet to separation chamber closes. preventing the

return of air to the system.

Replacement of the hurling water evaporated from the separa-

tion chamber is controlled by a solenoid valve connected to the

water supply and actuated by a float switch.

CONDENSA

TE RETURN CYCLE

The condensate r

eturn cycle begins when a float switch starts

a water pump on condensate rise. The condensate is pumped

into the boiler feed system until the preset low float switch set-

ting has been reached.

DUPLEX PUMPS

The second or lag pump of duplex water and/or air pumps

functions if the first or lead pump fails and automatically oper-

ates to double the capacity in the event of abnormal demand.

TEMPERA

TURE LIMIT SWITCH

Some units may be equipped with temperatur

e limit switches.

When located on the separation chamber, it is used to admit

cooling water if the hurling temperature exceeds a predeter-

mined limit.

A condition may be encountered where the temperature of the

condensate fluctuates intermittently to critically high levels,

where operation under vacuum could cause the condensate to

vaporize. A temperature limit switch can be installed on the

condensate receiver to prevent the air pump(s) from operating

where such a condition exists. Upon temperature drop the vac-

uum switch(es) will again control operation of the air pump(s).

V

ACUUM SWITCH ADJUSTMENTS

The vacuum switches ar

e adjusted and tested at the factory for

proper operation. The vacuum switch on the single unit and the

lead switch of the duplex unit is set to close at 3" Hg vacuum

and open at 8". The lag switch of a duplex unit is set to close

at 2" and open at 8".

These settings are suitable for all normal installations including

those having an accumulator tank or lift fitting when properly

piped. If settings must be readjusted, refer to manufacturer’s

instruction.

4

FIG. 4 100 & 150 VCD LIFT PIPE

ASSEMBLIES

FIG. 3

CUT-AWAY VIEW OF VCD PUMP WITH 50 VCD RECEIVER

25 VCD RECEIVERS ARE SIMILAR

CUT-AWAY VIEW OF VCD PUMP WITH 100 VCD

OR 150 VCD RECEIVERS