Bell & gossett, Domestic, Pumps – Bell & Gossett DN0136C Domestic Pump Vacuum Heating Units Series VCL User Manual

Page 12: Dealer ser vice

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. DN0136C November 2012

DEALER SER

VICE

If tr

ouble occurs that cannot be rectified, contact your local

B&G representative. He will need the following information in

order to give you assistance.

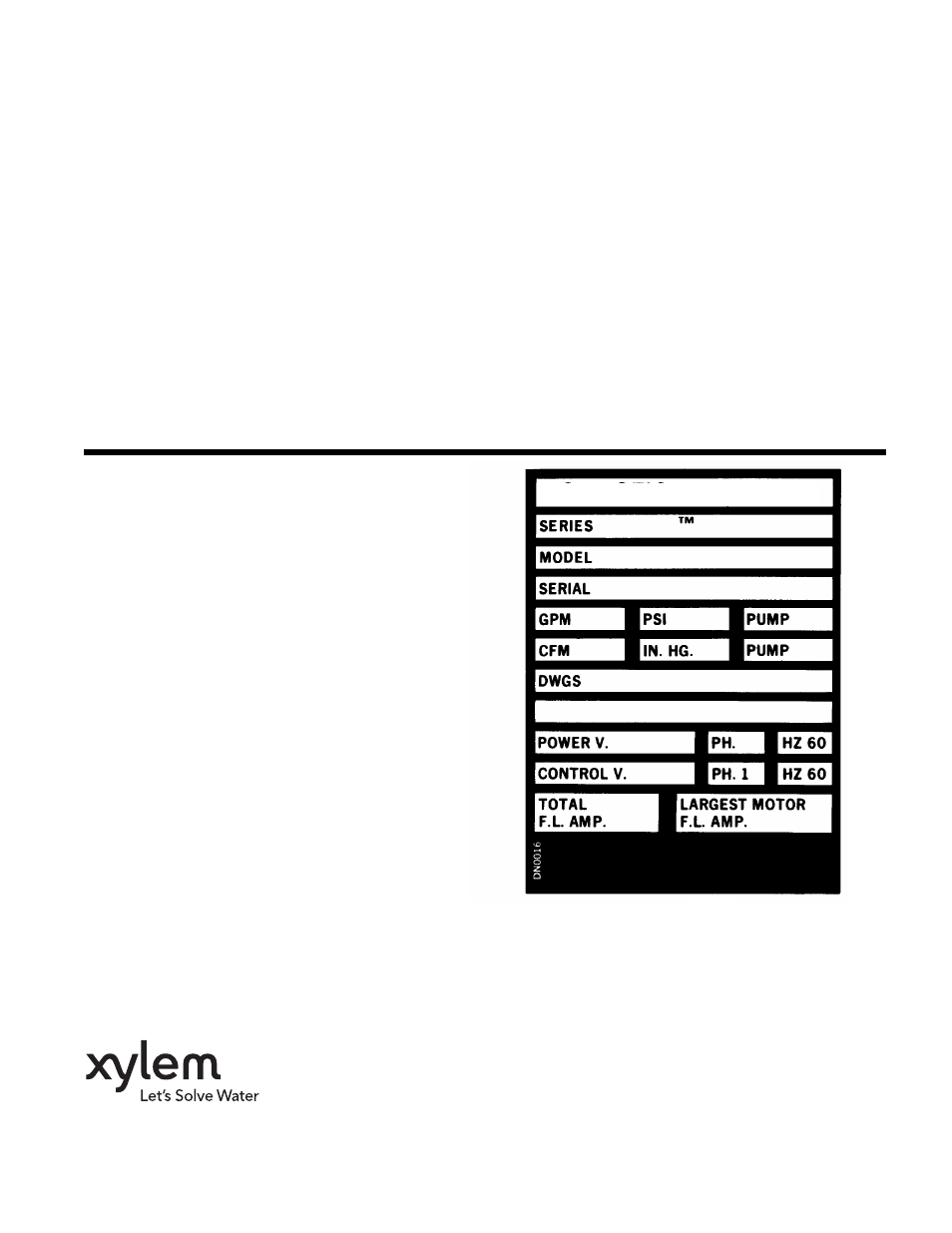

1. Complete nameplate data of pump and motor.

SEE RATING NAMEPLATE at right.

2. Suction and discharge pipe pressure gauge readings.

3. Ampere draw of the motor.

4. A sketch of the pump hook-up and piping.

5. Provide complete information on boiler control switches

and any motorized or solenoid valves in the boiler feed

piping.

SYSTEM

IS NOISY

1.

Banging in the steam mains is usually caused by “implod-

ing” in condensate lying in low points in lines. These

pockets can be eliminated by dripping low points, properly

supporting the pipe, or by increasing the pitch of the lines.

2. Improper dripping of the steam mains and risers; where

there is a rise in the steam main, or where it branches off

into a riser, a drip trap must be installed to the drain line.

3. The piping is too small to drain properly.

4. A defective trap is holding condensate in steam supply line.

PUMP DOES NOT RETURN ALL CONDENSA

TE

TO BOILER FEED SYSTEM (PUMP FLOODS)

1.

Pump is running backward looking down on motor.

Rotation of 3 phase motors may be corrected by inter-

changing any two of the three wires. Pump should run

clockwise.

2. Steam traps are blowing through causing condensate to

return at excessive temperatures. This may reduce the

capacity of pump below its rating, depending on the unit

and type of pump furnished. Traps should be repaired or

replaced.

3. The total pressure at the pump discharge is greater than the

pressure for which the pump was designed. Check the total

pressure which includes the boiler pressure, the friction

head and the static head.

4. A valve in the discharge line between pump and boiler is

closed or throttled too tightly. Check valve is installed

backwards.

5. Condensate is held up in system periodically by induced

vacuum in boiler or radiation then released in a flood when

pump starts. Install equalizer line per piping diagram.

6. The strainer is dirty thus retarding flow. Refer to instructions

for cleaning.

7. The impeller eye is clogged with trash.

8. Systems with accumulator tanks should have equalizer line

run from accumulator tank to steam header as shown on

pages 2 & 3: NOT from accumulator tank to pump receiver

NOR from pump receiver to steam header. Install vacuum

breaker on accumulator tank, NOT on pump.

9. Pump is too small for the system.

Bell & Gossett

Morton Grove, Illinois 60053

DOMESTIC

®

PUMPS