Troubleshooting series vl units – Bell & Gossett DN0135D Domestic Pump Vacuum Heating Units Series VL User Manual

Page 8

(3)

Place motor vertically with pump end up. Do not attempt

assembly of seal and impeller with shaft horizontal.

(4) The “carbon” of rotating part of seal should not be loose.

If it is, hold in place with grease, Using clean, lint free

cloth, wipe mating surfaces perfectly clean. Soap shaft

and push seal onto shaft so that carbon will contact

ceramic seal. If spacer is required, use grease to cause

spacer to adhere to bottom of seal after seal has been

put on shaft. Be sure spacer is on larger diameter of

shaft so that will not catch between shoulder and

impeller.

13. Replace impeller on shaft. Replace stainless steel washer

and secure impeller with capscrew or cap nut.

14. Place new gasket on pump volute and reassemble motor

and pump subassembly on pump volute.

15. Reconnect pump bleed line and motor wiring.

16. Close drain and slowly open inlet valves. See warning.

17. Jog to check motor rotation. See caution.

18. Observe operation thru several cycles.

8

CAUTION:

DO NOT REVERSE

Reverse operation can cause extensive damage to

pumps. Jog the motor to test for direction of rotation. Failure

to follow these instructions could result in serious injury or

death.

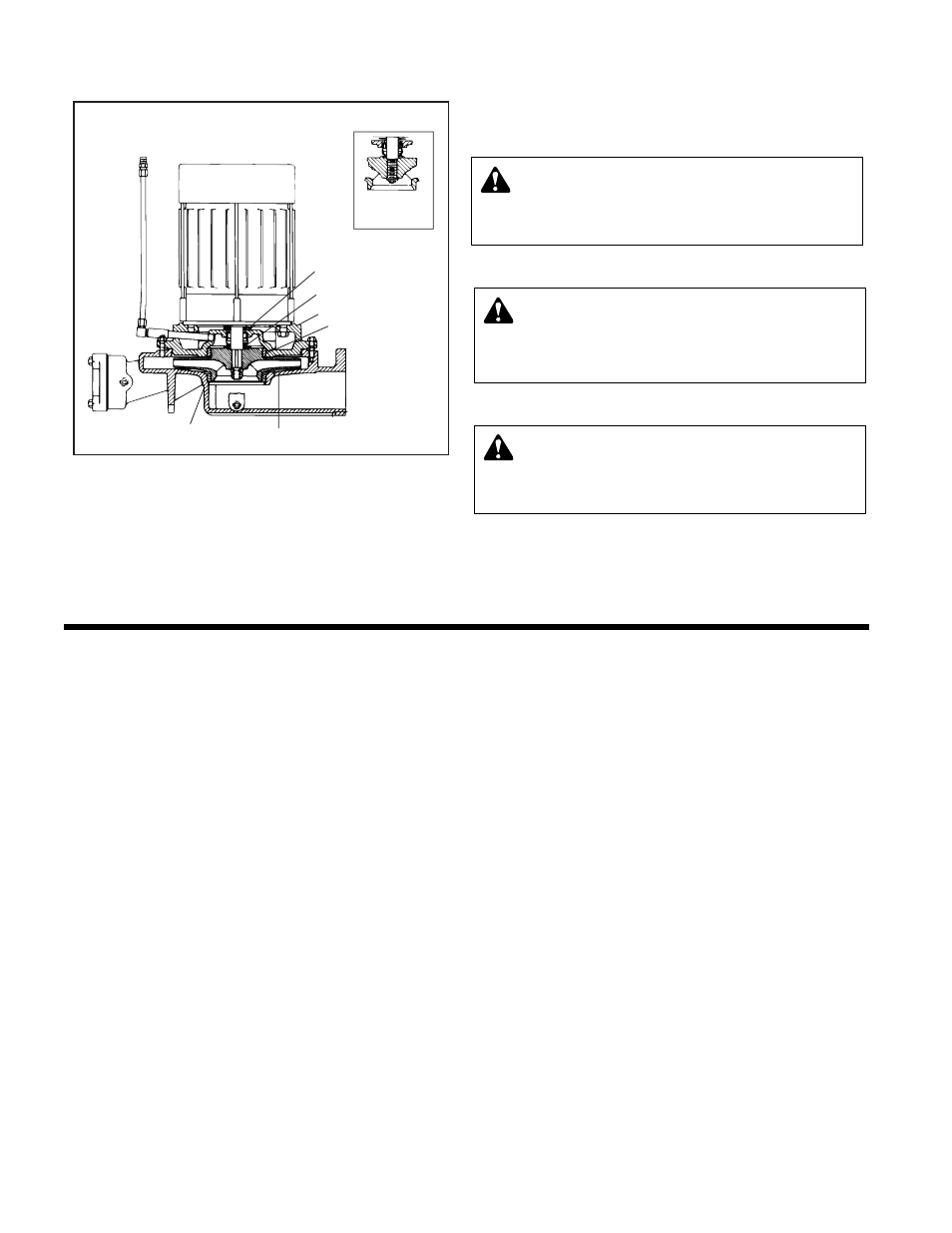

WATER

SLINGER

VIEW OF

THREADED

IMPELLER

WEAR RING

IMPELLER

2DPF03

VOLUTE

MOTOR BRACKET

MECHANICAL

SEAL

CAUTION:

DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR.

Inspect pump seal r

egularly for leaks Replace as required.

Failure to follow these instructions could result in serious

injury or death.

TROUBLESHOOTING SERIES VL UNITS

ALL UNITS ARE THOROUGHLY TESTED AT THE FACTORY BEFORE SHIPMENT AND SHOULD OPERATE SATISFACTORILY

WITHOUT FURTHER ADJUSTMENT IF PROPERLY INSTALLED AND IF NOT DAMAGED BY ROUGH HANDLING IN TRANSIT.

IF SYSTEM OR UNIT PERFORMANCE IS NOT SATISFACTORY, REFER TO THE FOLLOWING CHECK LIST.

PUMP WILL NOT START

1.

The power supply has been interrupted, disconnect switch

is open or selector switches improperly positioned.

2. Insufficient condensate accumulated to actuate float

switch.

3. Vacuum is not low enough to actuate vacuum switch.

4. Incorrect voltage for motor. Check voltage and wiring with

motor characteristics.

5. Incorrect starter for power supply.

6. The overload relays in the starter have tripped out and must

be reset. Ambient temperature may be too high.

7. Check float switch, vacuum switch or other control for

proper operation.

8. Wiring to control panel is incorrect or connections are loose.

PUMP DOES NOT RETURN ALL CONDENSA

TE TO

BOILER FEED SYSTEM (UNIT FLOODS)

1.

Pump is running backward looking down on motor.

Rotation of 3 phase motors may be corrected by inter-

changing any two of the three wires. Pump should run

clockwise.

2. Steam traps are blowing through causing condensate to

return at excessive temperatures. If 160°F is exceeded the

capacity of the pump may be reduced below its rating.

Traps should be repaired or replaced.

3. The total pressure at the pump discharge is greater than the

pressure for which the pump was designed. Check the total

pressure which includes the boiler pressure, the friction

head and the static head.

4. A valve in the discharge line between pump and boiler is

closed or throttled too tightly. Check valve is installed

backwards.

5. Condensate is held up in system periodically by induced

vacuum in boiler or radiation then released in a flood when

the pump starts. Install equalizer line.

6. The strainer is dirty thus retarding flow. Refer to instructions

for cleaning.

7. The impeller eye is clogged with trash.

8. The bellows type discharge valve fails to open. This may be

caused by the solenoid valve remaining in a closed posi-

tion, or dirt becoming lodged in the pressure release line.

Float switch failure may also cause the discharge valve to

remain shut. Replace the bellows type discharge with the

solenoid operated discharge valve. If solenoid discharge

valve has already been installed the solenoid may be stuck

shut or the float switch failed.

9. Systems with accumulator tanks should have equalizer

line run from accumulator tank to steam header: NOT

from accumulator tank to pump receiver NOR from pump

receiver to steam header. Install vacuum breaker on

accumulator tank, NOT on pump.

10. Pump is too small for the system.

11. Equalizer orifice between inlet and main compartments of

receiver is clogged.

W

ARNING: EXPLOSIBLE

Do not pr

essurize receiver. Isolate receiver during leak

test. Do not plug overflow. Do not restrict vent opening to

atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.