Bell & Gossett DN0135D Domestic Pump Vacuum Heating Units Series VL User Manual

Page 3

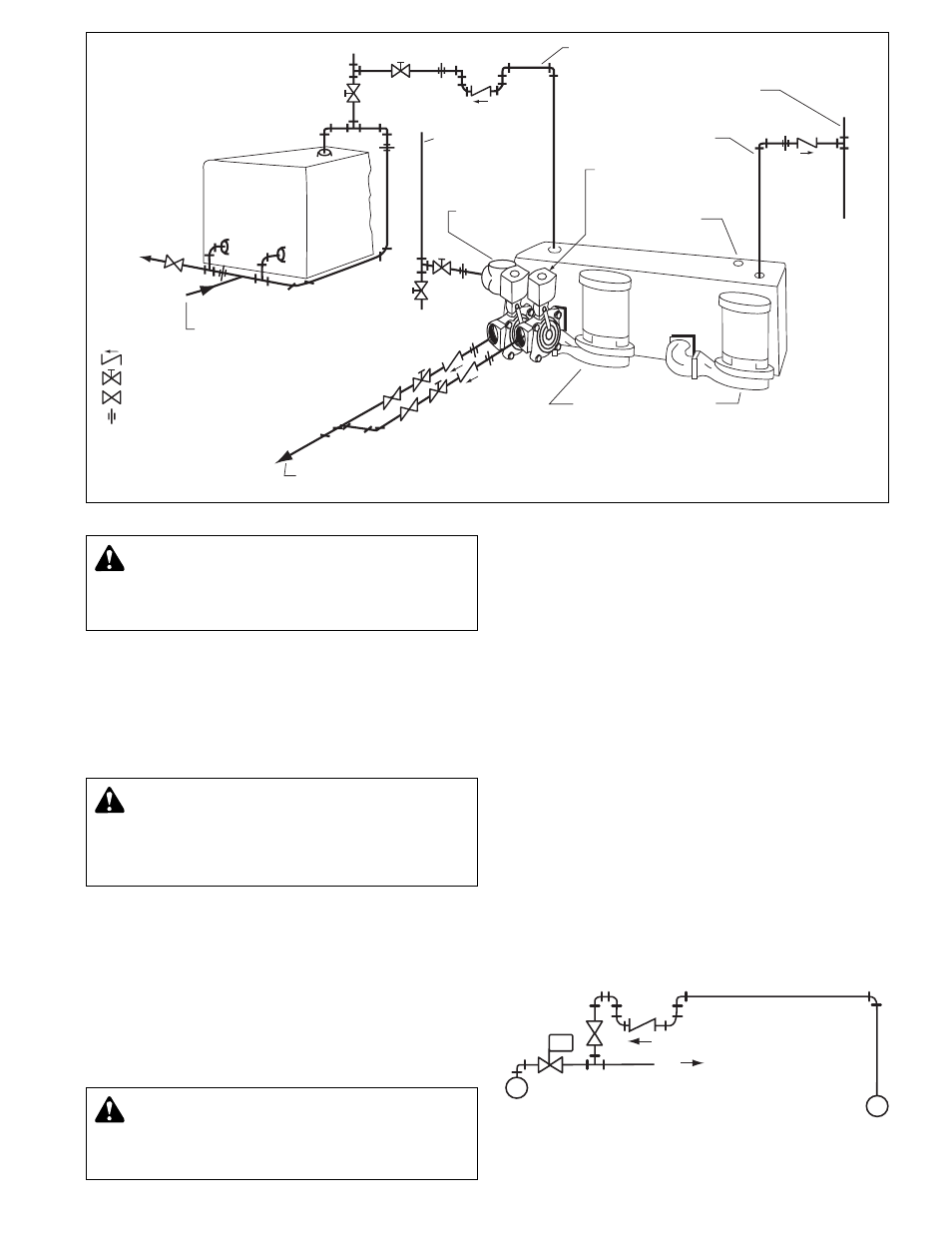

BOILER

TO

DRAIN

FROM BOILER

FEED SYSTEM

TO DRAIN

INLET

STRAINER

RETURN FROM

HEATING

SYSTEM

EQUALIZING LINE –

3

/

4

"

OPEN VENT ABOVE

BOILER WATER LINE

AIR VENT

DISCHARGE

VALVES

PRIMING

OPENING

TO DRAIN

CENTRIFUGAL PUMPS

– CHECK VALVE

– GATE VALVE

– STEAM OR PLUG COCK

– UNION

TO BOILER

FEED SYSTEM

Receivers ar

e non-code cast iron.

PRELIMINAR

Y INSPECTION

Assur

e that there is no shipping damage.

Assure that nameplate ratings agree with job specifications and

actual conditions.

HANDLING

Use car

e in installing unit.

LOCA

TION

Place unit for easy access to all parts. Allow adequate space

for servicing. Check ambient conditions.

NOTICE/TEMPERA

TURE LIMITS

Motors ar

e designed to operate in 104°F max. ambient.

Insulate or ventilate as required.

PIPING

(General)

Pipe the unit per the Elementary Piping Diagram. Locate and

support piping so as to not load the discharge valve.

PIPING (

Vent)

Install a vent pipe to atmospher

e. Pipe to be size of vent port

on unit. Do not restrict or reduce vent opening or exceed 20

feet vertical height unless an overflow connection is provided.

Series VL Units require a check valve in the vent line as shown

on the piping diagram (furnished with unit).

PRIMING POR

T

Pr

ovide a priming port as shown on piping diagram. Provide a

water supply for priming.

FLOA

T SWITCHES

Floats ar

e locked in place to prevent damage during shipment.

Remove shipping locks. Check factory settings. Floats are

adjustable for various levels of operation.

See page 7 for detailed instructions.

EQUALIZING LINE

An equalizing line must be installed with all Series VL units. This

line must be installed to prevent formation of a vacuum on the

radiation side of the system when steam stops flowing in the

mains. This vacuum may be higher than return line vacuum,

which would prevent condensate from flowing back to pump.

To correct this is an unzoned system, install equalizer line as

shown in the piping diagram. To correct this in a zoned system,

install equalizer line for each zoned section or install a vacuum

breaker on supply line on radiation side of each zone control

valve.

3

CAUTION:

UNIT LIFTING EYE

Use unit lifting eyes only to lift unit as shipped fr

om

factory. Unit must be empty and disconnected from pipes,

anchors and other restraints. Use proper rigging pro-

cedures. Failure to follow these instructions could result in

injury or property damage.

CAUTION:

NOT A CHEMICAL PUMP

Inject boiler feed compounds fr

om chemical feed tank

into boiler feed piping – never into condensate tank. Failure

to follow these instructions could result in injury or property

damage.

EQUALIZING CONNECTIONS FOR ZONED SYSTEMS

ZONE CONTROL

VALVE

STEAM MAIN

M

TO ZONE

RETURN MAIN

FIG. 3. SERIES VL PIPING DIAGRAM

WARNING: EXPLOSIBLE

Do not pr

essurize receiver. Isolate receiver during leak

test. Do not plug overflow. Do not restrict vent opening to

atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.