Description and inst allation – Bell & Gossett DN0135D Domestic Pump Vacuum Heating Units Series VL User Manual

Page 2

2

DESCRIPTION AND INST

ALLATION

The Series VL vacuum heating units ar

e designed to serve the

dual purpose of pumping accumulated condensate back to the

boiler feed tank and maintaining vacuum in the condensate

system. This vacuum will draw air out of the system on start-up

and facilitate the flow of steam thru the heating system.

One pump/vacuum producer/discharge valve assembly

controls both the condensate discharge and the production of

vacuum. Two pump (duplex) units have a second assembly for

backup and to provide extra capacity to handle peak loads.

Various electrical controls are offered to meet system require-

ments. These controls are normally supplied as part of the

assembled unit and a wiring diagram is furnished with the unit.

Refer to this electrical diagram as required.

The units respond to both changing condensate levels and

system vacuum requirements.

In operation the centrifugal pump circulates water (condensate)

thru the multi-jet nozzle creating multiple jets of water entering

the venturi. These jets entrain air and gasses creating a smooth

steady vacuum in the nozzle body and in the condensate

system. The air and gasses are separated in the receiver and

vented to atmosphere.

Low system vacuum or high water in the receiver will start the

pump to create vacuum and circulate water.

The solenoid operated discharge valve is opened in response

to the condensate level float switch. Controlled opening of the

discharge valve holds sufficient back pressure in the nozzle

body that the vacuum producer continues to function even

when discharging condensate (simultaneous rating).

When the vacuum and float switches have been satisfied and

the pump stops, the check valve in the nozzle body closes,

preventing the return of air and water to the system.

An internal orifice permits the vacuum in the receiver and in the

system to slowly equalize. Note that the vent line on the Series

VL requires a check valve to prevent return of atmospheric air

to the receiver. Without the check valve and orifice, a system

could develop high vacuum upon cooling holding the check

valve closed and thereby preventing flow of condensate into

the unit.

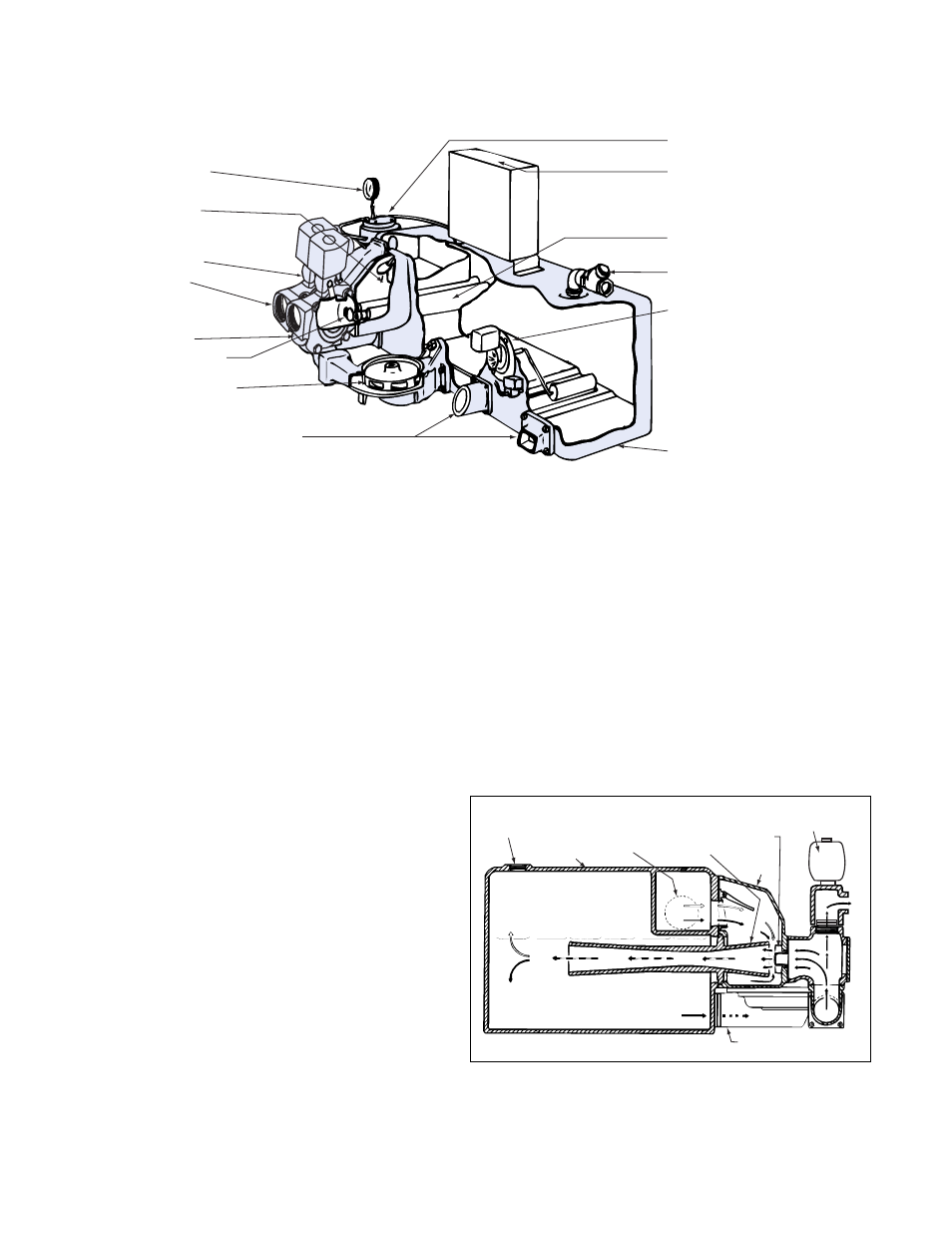

STRAINER

CONTROL PANEL

VENTURI

AIR VENT VALVE

FLOAT SWITCH

RECEIVER

MOUNTING PADS FOR DUPLEX

CENTRIFUGAL PUMPS

CENTRIFUGAL PUMP

MULTI-JET NOZZLE

DISCHARGE

MANIFOLD

SOLENOID

DISCHARGE VALVE

DISCHARGE

CHECK VALVE

VACUUM GAGE

DSK-1330

FIG. 1 SERIES VL

VACUUM UNITS 25,000-60,000 EDR

FIG. 2

SERIES VL VACUUM PRODUCER

AIR VENT

RECEIVER

INLET

MULTI-JET NOZZLES

VENTURI

NOZZLE

BODY

CENTRIFUGAL PUMP

DSK-1328

SOLENOID

DISCHARGE

VALVE