Dealer servicing – Xylem AC2008B Series HSC3 Base Mounted Centrifugal Pump User Manual

Page 22

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. AC2008B May 2012

ORDERING PARTS

The pumps covered by this manual have been designed and

built with certain replaceable wearing parts. The recom-

mended inventory of spare parts depends upon the installation

and the importance of continued operation.

For critical service requiring a minimum of “down time” a com-

plete or “quick change” rotating element is recommended.

For normal service, with repairs to be made in the field, the

following parts are recommended for stock.

1 set of bearings

1 set of casing wearing rings

1 set of casing gaskets, “O” rings and lip seals

2 mechanical seals (complete)

Parts should be ordered as far in advance of their use as pos-

sible since circumstances beyond the control of the company

may reduce existing stock. Not all parts are stocked and must

be manufactured for each order.

To facilitate rapid handling of your order for spare parts, be

sure to include the following information:

1. Serial number of the pump.

2. Name of the part.

3. Quantity of each part.

4. Material desired. (Parts will be furnished in original

materials unless specified as a material change. All material

substitutions should be discussed with the factory.)

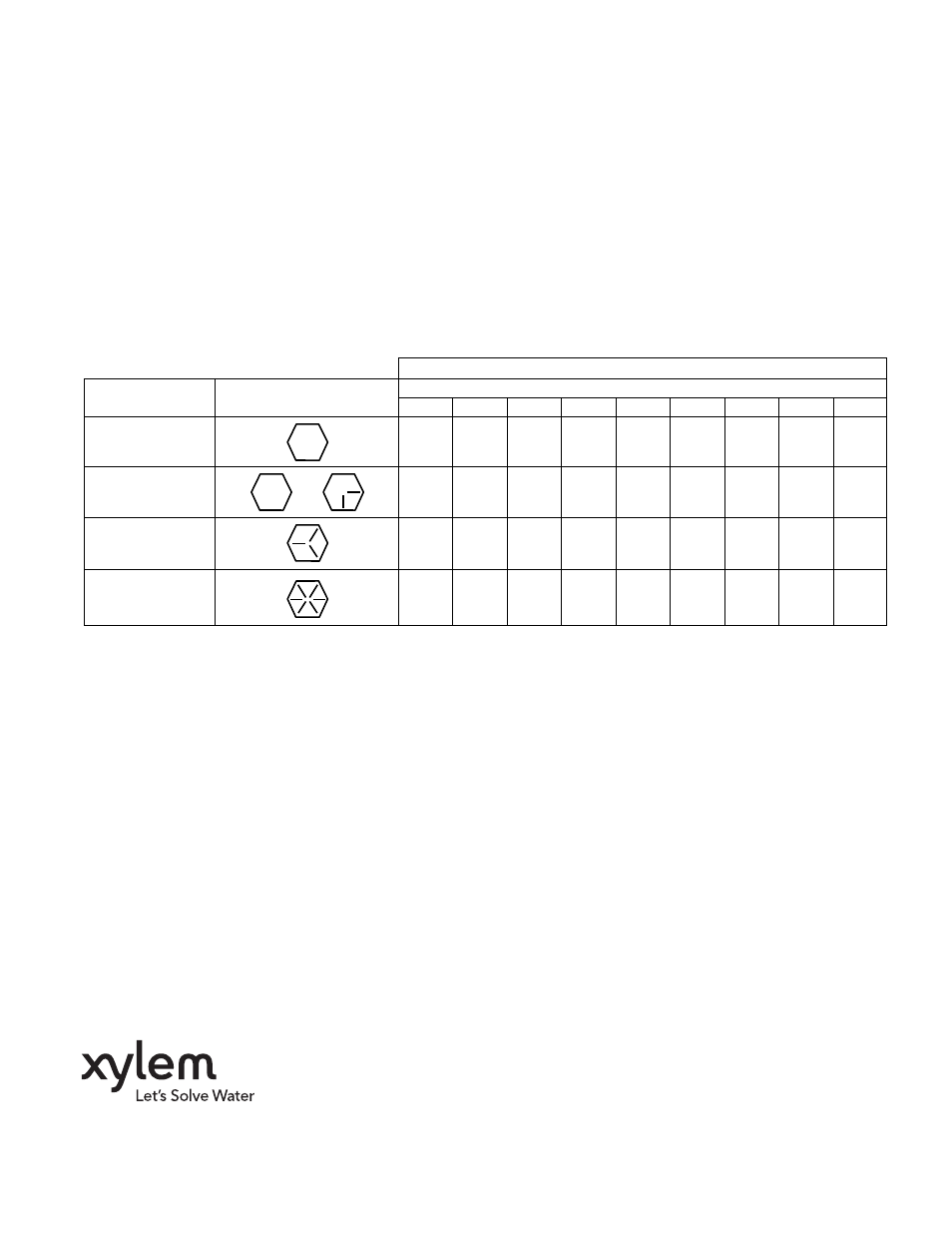

CAPSCREW TORQUE (FOOT-POUND)

CAPSCREW

HEAD

CAPSCREW DIAMETER

TYPE

MARKING

1

/

4

5

/

16

3

/

8

7

/

16

1

/

2

5

/

8

3

/

4

7

/

8

1

SAE Grade 2

6

13

25

38

60

120

190

210

300

Brass

Stainless Steel

or

4

10

17

27

42

83

130

200

300

SAE Grade 5

10

20

35

60

90

180

325

525

800

SAE Grade 8

13

28

46

75

115

225

370

590

895

DEALER SERVICING

If trouble occurs that cannot be rectified, contact your local

B&G Representative. He will need the following information in

order to give you assistance.

1. Complete nameplate data of pump and motor.

2. Suction and discharge pipe pressure gauge readings.

3. Ampere draw of the motor.

4. A sketch of the pumping hook-up and piping.