Xylem AC2008B Series HSC3 Base Mounted Centrifugal Pump User Manual

Page 17

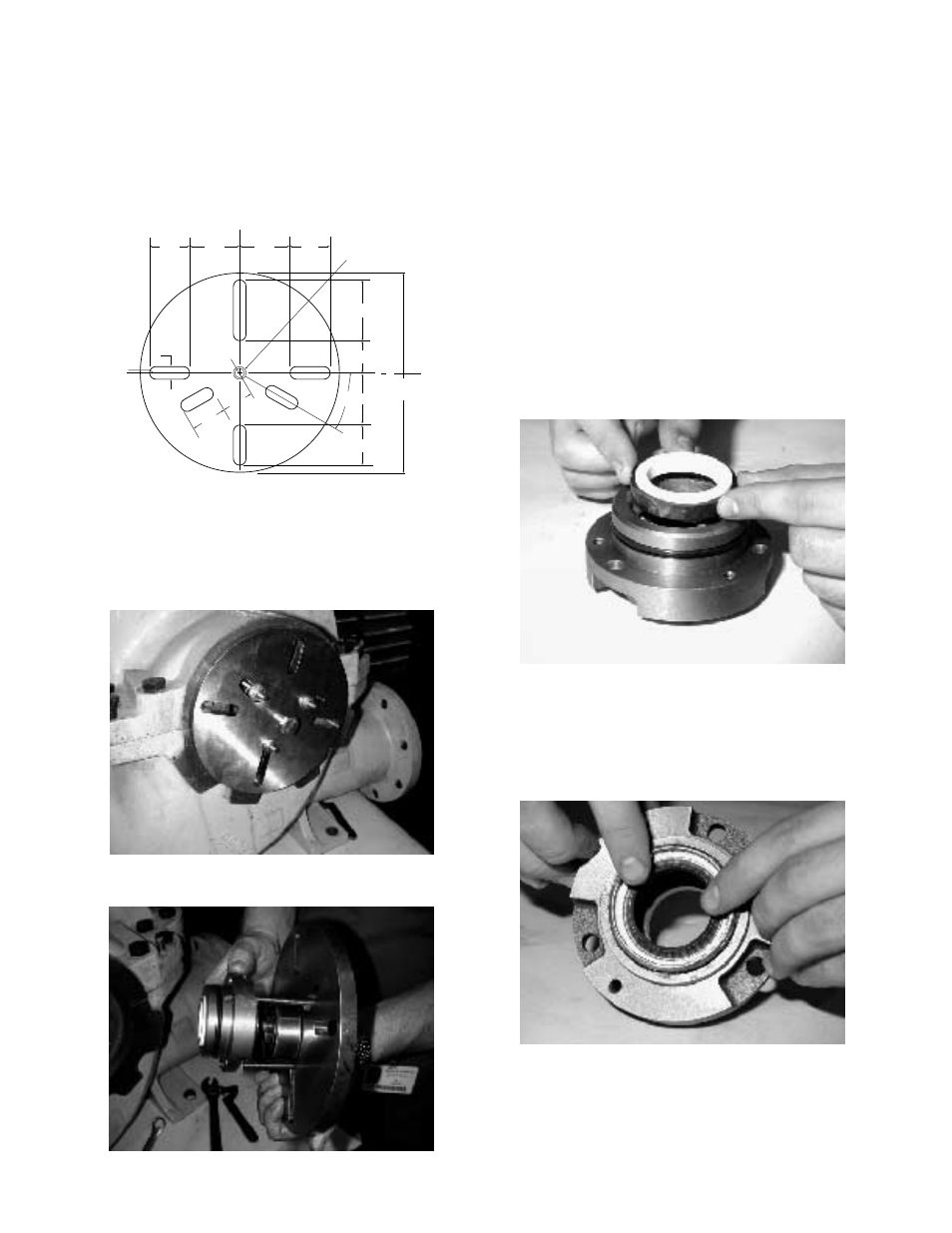

6. Insert threaded rods into the tapped holes in the gland

plate and install a fixture on the threaded rods to use a

puller. (See Illustration 10 for Dimensions of Universal

Fixture PN: AC2394) Using the puller, tighten the bolt in

the center of the fixture to remove the bearing and gland

plate from the shaft. (See Photos 1 and 2).

CAUTION: FAILURE TO REMOVE THE SOCKET-HEAD

CAPSCREWS BEFORE TRYING TO PULL THE BEAR-

INGS OFF COULD CAUSE DAMAGE TO THE PUMP.

7. Remove the inboard bearing and gland plate in the same

manner.

NOTE: The locknut and lockwasher are not used on the

inboard bearing.

CAUTION: DO NOT REUSE THE BALL BEARINGS.

8. Remove the mechanical seal head from the pump shaft.

NOTE: To ease in the removal of the mechanical seal

heads, you may want to use 2 allen wrenches as hooks or

form hooks from wire.

9. Drive the lip-seals, the mechanical seal seats, from each

of the gland plates by tapping on them from the rear.

10. Remove the O-rings from each of the gland plates.

Assembly of the Mechanical Seals and Bearings

without removing the Upper Half of the Casing

NOTE: All bearings, O-rings, and lip-seals should be replaced

with new parts during assembly. All usable parts should be

cleaned of foreign matter before reassembly.

NOTE: Reassemble the pump by starting on the outboard end

(the end opposite the coupling). This end locks the rotating

element into position in the casing.

1. Press the stationary mechanical seal seat into the gland

plate until it bottoms out against the bore. Lightly lubri-

cate the bore to ease assembly. (See Photo 3)

2. Press a new lip seal into the gland plate. Before installing

the lip seal, lubricate the lip-seal with lightweight oil. Note:

Lip seals should sit against machined shoulder in the

gland plate. The lip seal should face away from the

mechanical seal seat. (See Photo 4)

1.75"

1.75"

2.0"

2.0"

.437 Ø DRILL THRU

FOR .500-13

UNC-2B THREAD

2.44"

1.25"

1.75"

2.0"

30

∞

TYP

1.38"

1.25"

TYP

.25R

.50 TYP

8.0" Ø X .50 THK MIN.

H.R. STEEL

17

Illustration 10 – Dimensions for Universal Fixture (PN: AC2394)

Photo 1 – Removal of bearing and

gland plate using universal fixture

Photo 3 – Assembly mechanical seal seat into gland plate

Photo 4 – Assembly of lip seal into the gland plate

Photo 2 – Gland plate and bearing removed from stuffing box