Xylem AC2008B Series HSC3 Base Mounted Centrifugal Pump User Manual

Page 19

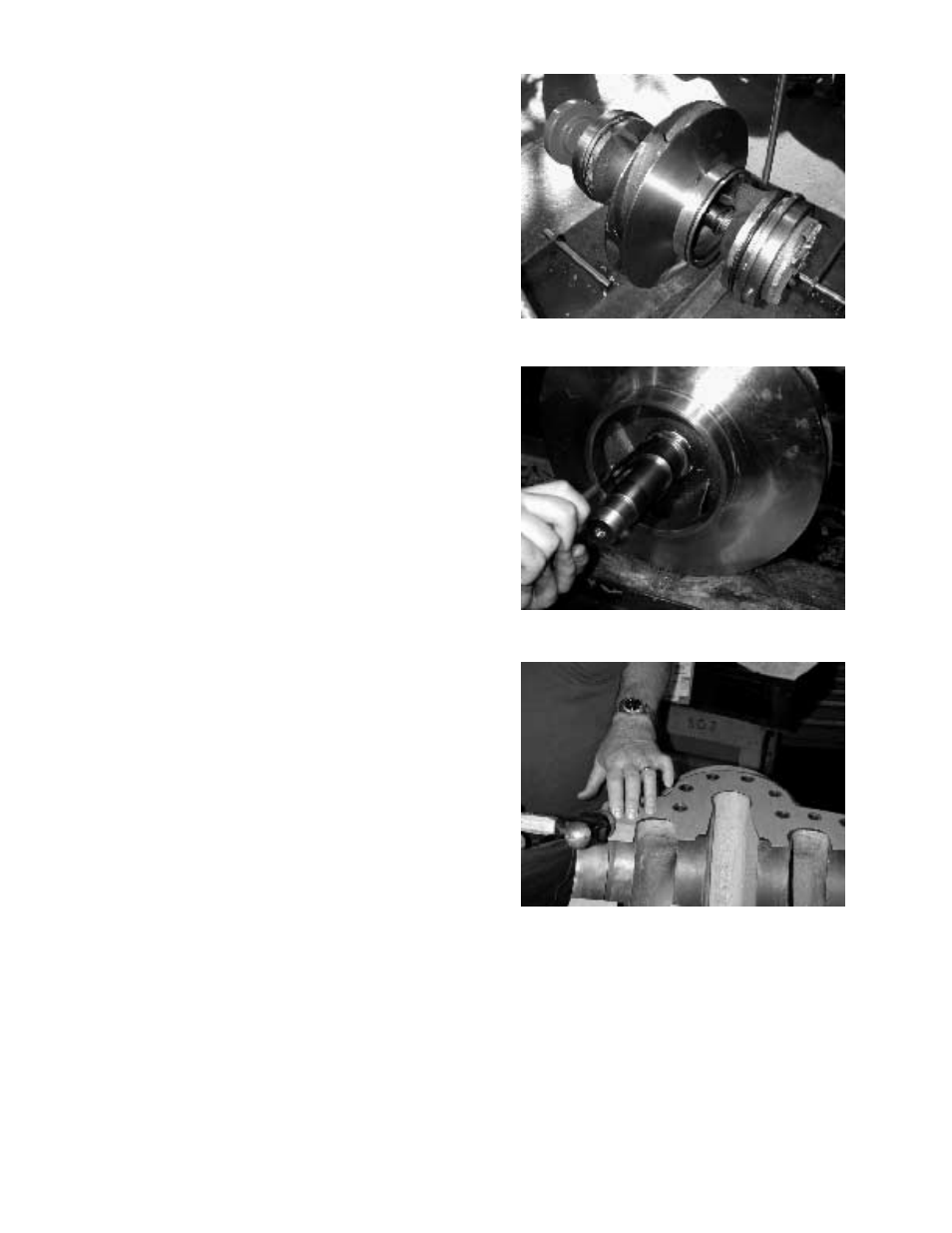

5. Tap the stuffing boxes with a soft-headed hammer to

break the seal between the stuffing box and lower casing

half, and lift the rotating element out of the lower casing.

Rotating element may be removed to a suitable location

for repair.

NOTE: A spare rotating element can be installed at this

point. (See Photo 7)

6. Remove the capscrews from each of the bearing housings

and remove the bearing housings by placing two cap-

screws in the jackscrew holes provided.

7. Bend back the lockwasher tab and remove both the lock-

washer and locknut from the outboard end of the shaft

(the opposite side of the coupling).

8. Remove the capscrews holding gland plate to the stuffing

box.

9. Insert threaded rods into the tapped holes in the gland

plate and install a fixture on the threaded rods to use as a

puller. (See Illustration 10 on page 17, for dimensions of

Universal Fixture). Using the puller, tighten the bolt in the

center of the fixture to remove the bearing and gland plate

from the shaft. If the bearing does not come off the shaft,

insert a spacer between the center bolt and the shaft, and

retighten the bolt. Remove the inboard bearing and gland

plate in the same manner. (See Photos 1 and 2 on page 17)

NOTE: The locknut and lockwasher are not used on the

inboard bearing.

10. Remove the gland plates from the stuffing boxes and

remove the O-rings from the stuffing boxes.

CAUTION: DO NOT REUSE THE BALL BEARINGS.

11. Remove the mechanical seal head from the pump shaft.

12. Drive the lip-seals, the mechanical seal seats, from each

of the gland plates by tapping on them from the rear.

13. Remove the O-rings from each of the gland plates.

14. Remove the two casing rings from the impeller and

remove the O-rings from each of the casing rings.

15. Remove the impeller-retaining ring with retaining pliers.

(See Photo 8). Heat the impeller hub on both ends to

350°F maximum, and pull or push the impeller from the

shaft. (Instead of heating the impeller, you may press

impeller off the shaft, if press is available.)

NOTE: Press away from the coupling end.

NOTE: For impellers with replaceable rings; remove the

rings, if necessary, by cutting with a cold chisel.

16. Remove the impeller key from the shaft.

19

Photo 7 – Rotating element

Photo 8 – Removal of impeller retaining ring

Photo 9 – Trimming casing gasket