Xylem AC2008B Series HSC3 Base Mounted Centrifugal Pump User Manual

Page 21

21

14. Lubricate and roll the O-rings into the groove in each

stuffing box.

NOTE: At this point reassemble the rotating element by

starting on the outboard end first (the end opposite the

coupling) as this end locates the settings of the mechani-

cal seal.

IMPORTANT: Steps 11 through 21 must be completed,

on the outboard end, within 10 to 12 minutes to assure

proper placement of the mechanical seals.

15. Lightly coat the outboard end of the pump shaft with P-80

Rubber Lubricant Emulsion, vegetable oil, or equal and

slide the mechanical seal head onto the shaft. (See Photo

11)

16. Slide the stuffing box, with the gland plate, fully on the

shaft, being very careful that the head and seat of the

mechanical seal do not get damaged. COMPRESS THE

SEAL SPRING ONLY AS FAR AS REQUIRED TO INSTALL

THE BEARINGS. (See Photo 12)

17. Fill lip seal cavity with approximately .50 ounces of

grease.

18. Heat the ball bearings using dry heat to 10% – 15%

soluble oil and water, or an induction heater.

CAUTION: DO NOT EXCEED A TEMPERATURE OF 275°F.

19. Using gloves, slide the heated bearing onto the shaft

against the shaft shoulder. (See Photo 5 on page 18)

20. Install the locknut and lockwasher on the outboard end of

the shaft. Make certain that the locknut is secure and

bend over the tabs on the lockwasher. (See Photo 6 on

page 18)

21. Allow the bearing to cool to room temperature. Coat the

exposed sides of the bearing with two or three ounces of

recommended grease.

22. Coat the inside of the bearing housing with grease and

slide it into place over the bearing. Attach the bearing

housing to the stuffing box with the capscrews.

23. Repeat steps 15 through 22 for the inboard end.

IMPORTANT: Steps 15 through 25 and must be com-

pleted within 10 to 12 minutes to assure proper place-

ment of the mechanical seal.

NOTE: A locknut and lockwasher are not installed on the

inboard end of the pump shaft.

24. Reinstall the coupler on the end of the shaft.

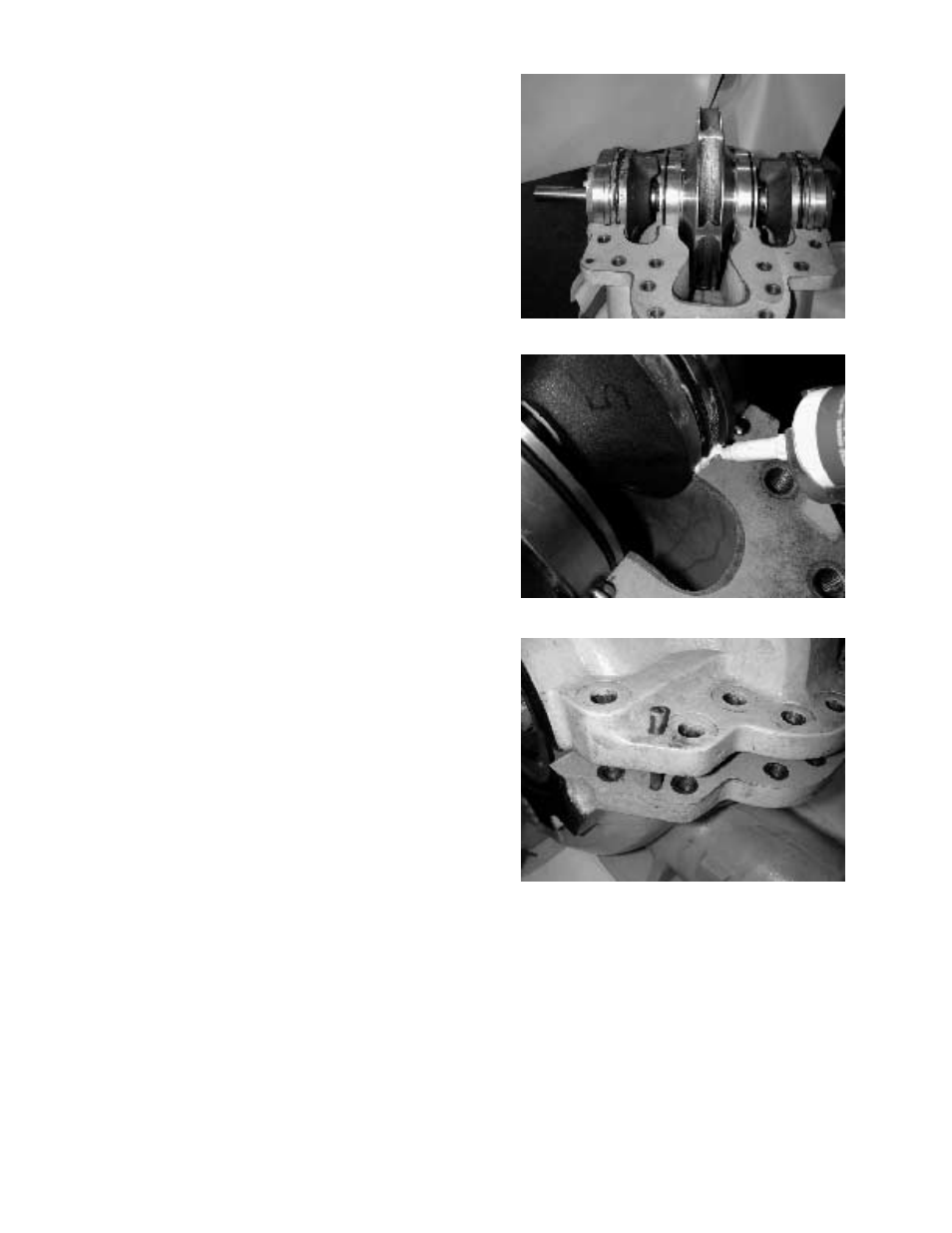

25. Set the rotating element in the pump casing, assuring cor-

rect rotation. Locate both stuffing box tongues in their

respective casing grooves. Locate the pins in the stuffing

box and the casing wear rings in their respective slots at

the casing parting surface. Correct any O-ring bulging.

(See Photo 13)

CAUTION: DO NOT CUT OR DAMAGE THE O-RINGS

WHEN LOWERING THE ROTATING ELEMENT INTO

POSITION. WHEN ALL FOUR ANTI-ROTATION PINS

ARE LOCATED CORRECTLY, THERE WILL BE SOME

CASING RING LOOSENESS.

26. Apply a small bead of Dow Corning RTV silicone sealant

or equal at the parting line on top of gasket at the stuffing

box O-rings. (See Photo 14)

27. Locate the upper half of the casing into place using the

tapered dowel pins and install the casing main joint bolts

(See Photo 15). The casing joints should be tightened to

the following torques: 140 ft.-lb. minimum for

5

/

8

"-11

hex head cap screws (Grade 5); 350ft.-lb. minimum for

7

/

8

"-9 Ferry Cap Counterbore screws (Grade 8). Bolt

torquing pattern is shown in Illustration 9 on page 12.

NOTE: Torque values are essential in obtaining proper

gasket compression so no leakage can occur at the main

joint.

28. Rotate the shaft by hand to assure that it turns smoothly

and it is free from rubbing or binding.

29. Assemble the coupler and check alignment, following the

instructions on page 7. Replace the coupler guard.

Photo 13 – Rotating element inside casing

Photo 14 – Addition of sealant

Photo 15 – Casing mainjoint