Xylem AC2008B Series HSC3 Base Mounted Centrifugal Pump User Manual

Page 18

18

3. Lubricate and roll the O-ring into the groove in the gland

plate.

IMPORTANT: Steps 4 and 5 must be completed within

10 to 12 minutes to assure proper placement of the mech-

anical seals.

4. Lightly coat the outboard end of the pump shaft with P-80

Rubber Lubricant Emulsion, vegetable oil, or equal and

slide the mechanical seal head onto the shaft. Do not

compress the seal spring at this time.

CAUTION: USE A FLASHLIGHT AND MAKE SURE THE

MECHANICAL SEAL SPRING IS SEATED PROPERLY

INTO THE SPRING HOLDER AND AROUND THE

BELLOWS OF THE MECHANICAL SEAL BEFORE

CONTINUING.

5. Slide the gland plate, over the shaft, being very careful

that the head and the seat of the mechanical seal do not

get damaged. Then press the gland plate with the O-ring

into the stuffing box and tighten the socket-head

capscrews.

NOTE: Because of the compression of the O-ring, it may

be difficult to press the O-ring into the stuffing box. Use

longer socket-head capscrews to start the gland plate

into the stuffing box. Draw-up the bolts evenly until the

gland plate is secure in the stuffing box. To prevent the

mechanical seal spring from pushing the gland plate back

out of the stuffing box, remove one long socket-head

capscrew at a time and replace with a regular socket-

head capscrew.

6. Heat the ball bearings using dry heat or 10% – 15%

soluble oil and water, or an induction heater.

CAUTION: DO NOT EXCEED A TEMPERATURE OF 275°F.

7. Fill up the lip seal cavity with approximately .50 ounces of

grease.

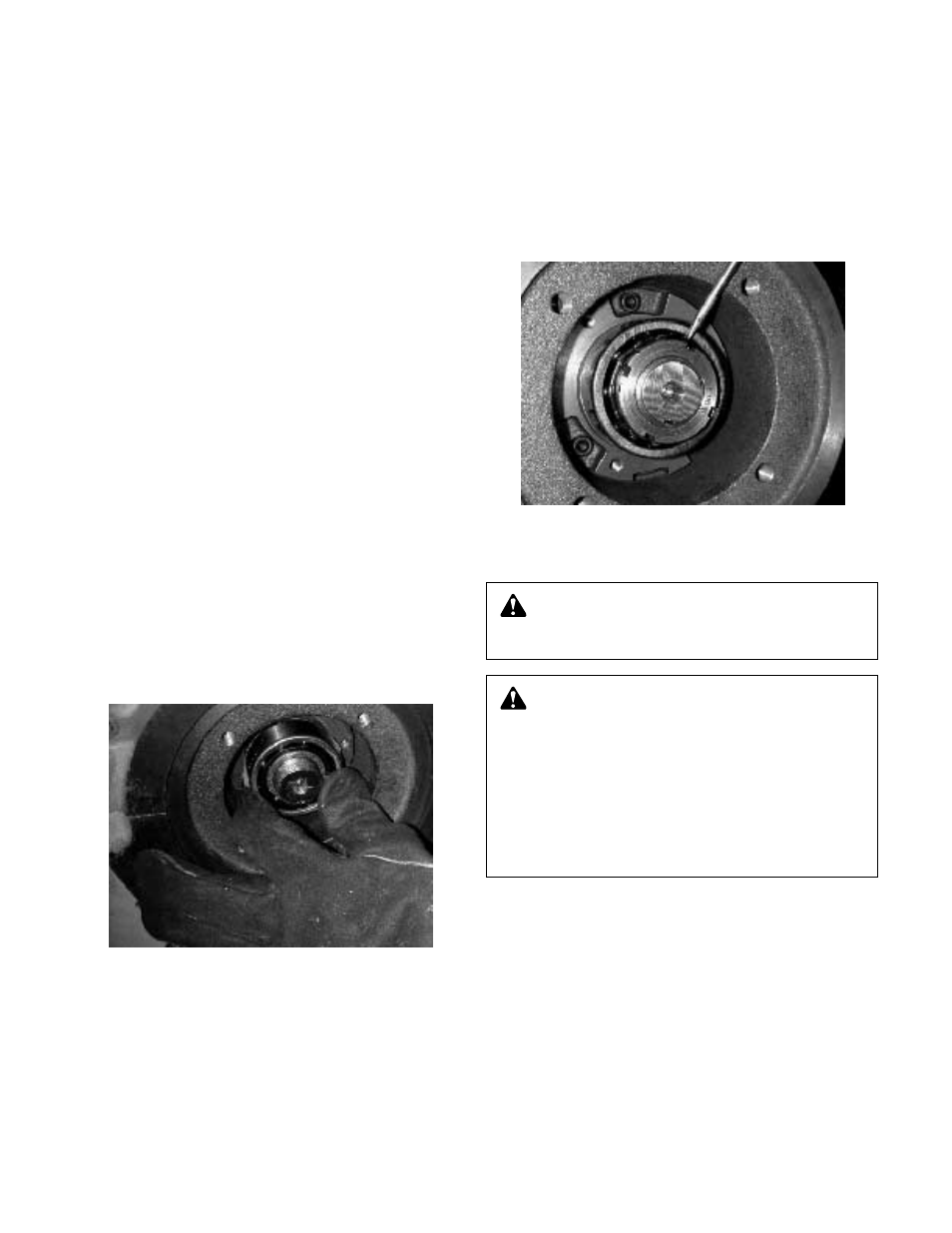

8. Using gloves, slide the heated bearing onto the shaft

against the shaft shoulder. (See Photo 5)

9. Install the locknut and lockwasher on the outboard end of

the shaft. Make certain that the locknut is secure and

bend over the tabs on the lockwasher. (See Photo 6)

10. Allow the bearing to cool to room temperature. Coat the

exposed sides of the bearing with two or three ounces of

recommended grease.

11. Coat the inside of the bearing housing with grease and

slide it into place over the bearing. Alternately tighten the

bearing housing capscrews so as not to “cock” the bear-

ing housing causing bearing to bind.

12. Repeat steps 1 through 11 for the inboard.

NOTE: A locknut and lockwasher are not installed on the

inboard end of the pump shaft.

13. Reinstall the coupler and check for alignment, following

the instructions on page 8. Install the coupler guard

(Refer to page 7).

Dismantling the Pump when it is required to remove

the Rotating Element of the Pump

1. Close valves on suction and discharge sides of pump. If

no valves have been installed, it will be necessary to drain

the system.

2. Remove the coupler guard. For spacer couplers, loosen

the capscrews which secure the coupler flanges to the

coupler hubs. Remove the coupler flanges and sleeve by

compressing the flanges and pulling out from beneath the

hubs or by loosening the allen set screws and sliding the

hubs back on the shafts. Remove the coupler hub from

the pump shaft. For non-spacer couplers, loosen allen set

screws and slide flanges back on shafts and remove

rubber element.

3. Remove all casing main joint capscrews and dowel pins.

4. Tighten the jacking screws in the upper half of the casing

to separate the upper and lower casing halves. Then lift

off the upper half of the casing.

Photo 5 – Installation of bearing

Photo 6 – Installation of lockwasher and locknut

CAUTION: Extreme Temperature Hazard

Allow pump temperatures to reach acceptable levels

before proceeding. Open drain valve, do not proceed until

liquid stops coming out of drain valve. If liquid does not

stop flowing from drain valve, isolation valves are not seal-

ing and should be repaired before proceeding. After liquid

stops flowing from drain valve, leave drain valve open and

continue. Remove the drain plug located on the bottom of

the pump housing. Do not reinstall plug or close drain

valve until reassembly is completed. Failure to follow these

instructions could result in property damage and/or moder-

ate personal injury.

WARNING: Unexpected Start-up Hazard

Disconnect and lock out power before servicing.

Failure to follow these instructions could result in serious

personal injury or death and property damage.