Xylem AC2008B Series HSC3 Base Mounted Centrifugal Pump User Manual

Page 20

20

Reassembly of the Pump when it is required to

remove the Rotating Element of the Pump

NOTE: All bearings, O-rings, lip-seals, mechanical seals,

gaskets, impeller rings, and casing rings should be replaced

with the new parts during assembly. All reusable parts should

be cleaned of all foreign matter before reassembling. The main

casing joint gasket can be made using the upper and lower

half as a template. Lay the gasket material on the casing joint.

Trim the gasket by lightly tapping with a ball peen hammer

so that it is flush with the inside edges of the casing. (See

Photo 9 on page 19) Do not hit casing edge with hammer hard

enough to round edge.

NOTE: Precut-casing gaskets can be ordered to minimize the

amount of trimming.

1. Before assembling the rotating element prepare the

casing and install the casing gaskets to the parting line.

2. Clean the gasket surfaces of the casing. Apply Scotch

3M-77 spray adhesive or equivalent to the lower half of

the casing.

3. Within one minute of spraying, set the untrimmed gaskets

in place on the lower half of the casing, align the holes in

the gaskets with the holes in the casing, and press the

gaskets firmly against the lower half of the casing face in

the area coated by the adhesive.

4. Trim the gaskets flush with the lower casing bores. (See

Photo 9 on page 19)

CAUTION: MACHINED-CASING BORES MUST

REMAIN SHARP AT THE CASING PARTING LINE.

GASKETS MUST BE FLUSH WITH THE BORE IN

ORDER TO CONTACT O-RINGS. LEAKAGE CAN

RESULT AROUND THE STUFFING BOX O-RING IF

THIS STEP IS NOT PROPERLY FOLLOWED.

5. Assemble the impeller key in the shaft key slot.

NOTE: For impeller with replaceable rings, heat each new

ring (approximately 300°F-400°F for bronze) and slide

onto the impeller. Using gloves, hold rings against the

impeller shoulder until cool.

6. Check the impeller and casing to determine the correct

relationship. Heat the impeller evenly to 300°F maximum

to expand the bore. (Impeller may be pressed onto the

shaft instead of heating if a suitable press is available.)

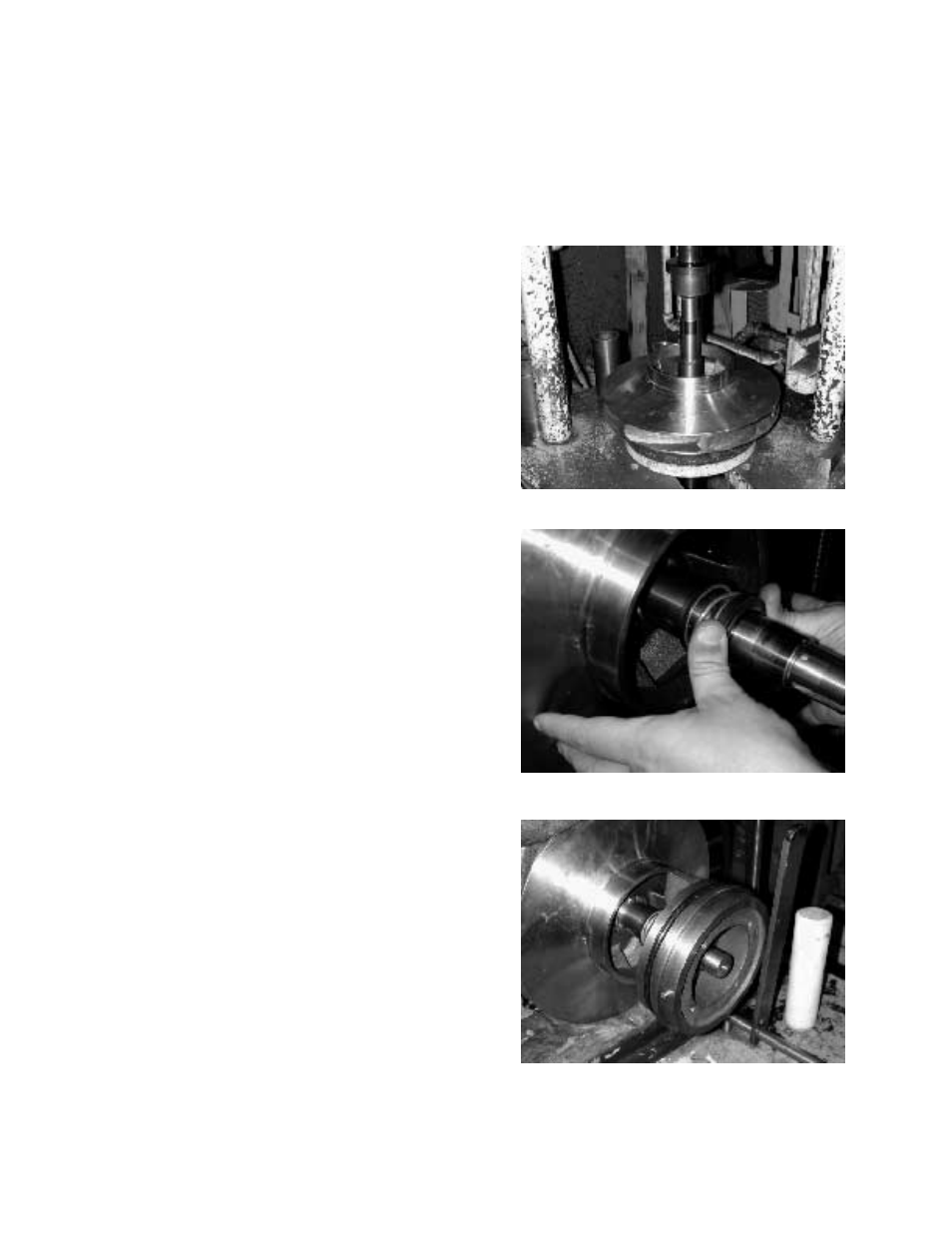

(See Photo 10)

7. Using gloves, from the outboard end, slide the impeller on

the shaft against the shaft shoulder, and install the retain-

ing ring.

8. Lubricate and roll an O-ring into the groove in each of the

casing rings. Then slide the casing rings over the impeller.

9. Thoroughly clean the gland plates and stuffing boxes to

prevent dirt from entering the seal during startup.

10. Press the stationary mechanical seal seats into both of

the gland plates. Lightly lubricate the gland plates to ease

assembly. (See Photo 3 on page 17)

11. Press new lip seals into the gland plates. Before installing

the lip seals, lubricate the lip seals with lightweight oil.

NOTE: Lip seals should sit against the machined shoulder

in the gland plates. The lip seals should face away from

the mechanical seal seats. (See Photo 4 on page 17)

12. Lubricate and roll the O-rings into the grooves in each

gland plate.

13. Press the gland plates into the stuffing boxes and secure

using the socket-head capscrews.

NOTE: Because of the compression of the O-ring, it may

be difficult to press the O-ring into the stuffing box. Use

longer socket-head capscrews to start the gland plate

into the stuffing box. To prevent the mechanical seal

spring from pushing the gland plate back out of the stuff-

ing box, remove one long socket-head capscrew at a time

and replace with a regular socket-head capscrew.

Photo 11 – Mechanical seal head installation

Photo 10 – Pressing impeller on shaft

Photo 12 – Installation of stuffing box