The pump station experiences excessive vibration, The pump station cycles or hunts erratically – Xylem 10 001 247 R2 TechnoForce Package System User Manual

Page 26

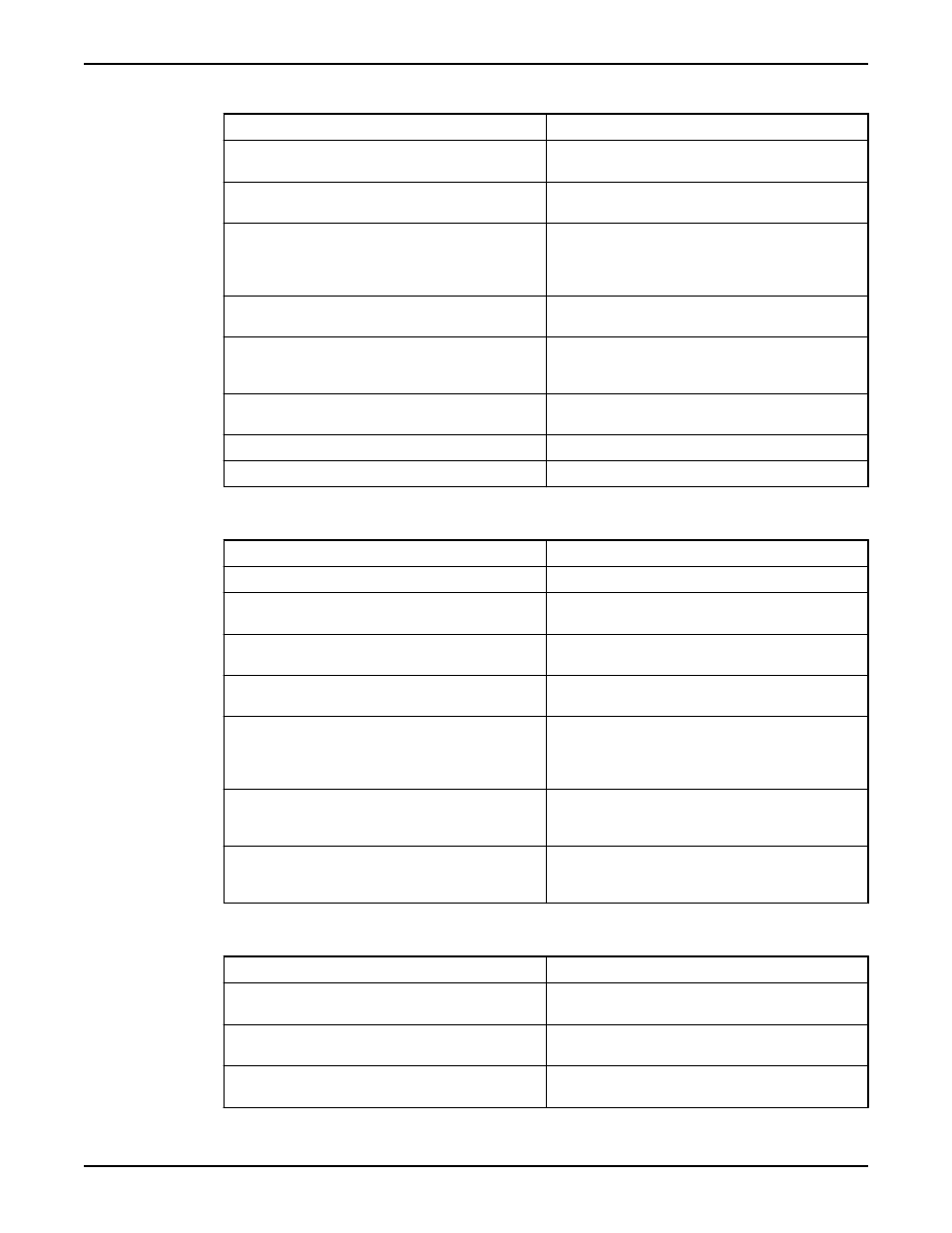

The pump station experiences excessive vibration

Cause

Remedy

The motor, pump, or piping is loose.

Make sure that all fasteners and components are

properly tightened.

Pump station vibration dampers are missing or

improperly installed.

Check for properly installed pump station vibration

dampers.

Pumps are running off their design curve.

Check the application. Is the system running in an open

discharge condition (excessive flow rate)? For example, is

the system filling a large irrigation line for the first time

of the season?

Air or gases are present in the pumped liquid.

Check water supply lines and tanks. Check for air or gases

in liquid. Bleed the lines.

Discharge piping is plugged.

Check discharge piping/valves. Could the piping be

plugged? Could the pump be plugged? Are the isolation

valves open? Clear any clogs.

Supply piping has excessive suction/lift conditions or

friction loss.

Check for excessive suction/lift conditions or friction loss

on supply piping.

The impeller is bound or worn.

Take the pump to an authorized pump repair facility.

Pumps and pipes are not properly aligned.

Correct the alignment between pumps and pipes.

The pump station does not shut down and no water is used

Cause

Remedy

The pump station is in Hand or Manual mode.

Put the system in the AUTO position.

The system pressure is set beyond capability of the

station.

Check the system set pressure. Is this duty point beyond

the capability of the pump station?

The RTDs are incorrectly installed.

Check to make sure that the RTDs are installed correctly.

(CS only)

There are leaks or broken pipes.

Check for broken pipes or leaks. Does the system

pressure decrease if the pump station is turned off?

The diaphragm tank is faulty.

Check for a properly installed diaphragm tank. Has the

tank failed? Has the tank been charged to the proper

operating pressure before installation? (~10 psi below

the desired set point)

The pressure transducers are faulty.

Check the pressure transducers. Does the actual

mechanical gauge pressure match the pressure

displayed on the VFDs and the PLC?

A check valve is malfunctioning.

Check for malfunctioning check valves. Does the system

hold pressure when the pump package is shut down?

Replace faulty valves.

The pump station cycles or hunts erratically

Cause

Remedy

The pumps are oversized for the current demand.

Check the application. Possibly increase the size of the

bladder tank for low demand situations.

The inlet pressure is fluctuating.

Check the application. Possibly increase the size of the

bladder tank for low demand situations.

There are leaks or broken pipes.

Check for broken pipes or leaks. Does the system

pressure decrease when the pump station is turned off?

Troubleshooting

24

TechnoForce Package System Mechanical Installation, Operation, and Maintenance Manual