Deep well jet pump system layouts – Xylem IM125 R02 RJA & RJDS Quick Set User Manual

Page 8

8

INSTALLATION STEPS

Step 1.

FOR YOUR SAFETY turn off electrical

power supply at the service entrance before connecting

or disconnecting any wiring to the pump to avoid any

possible electrical shock hazard.

Step 2. Drain the holding tank. Also disconnect the drive

pipe and the suction pipe, the service line, and if necessary,

the volume control line. Remove old pump.

Step 3. Place the jet pump on a level, solid foundation. If

you are also replacing the existing pressure tank, refer to

Section 7 in this manual.

Step 4. Connect the drive pipe and suction pipe, the service

line and, if necessary, the air volume control line. Use either

non-toxic pipe sealing compound or tape on male thread

joints of galvanized pipe (tape or cement on plastic pipe) to

facilitate making air tight joints.

Step 5. Wire the motor.

The Red Jacket convertible jet pump is wired to the pressure

switch. The pressure switch must be grounded in compliance

with the National Electrical Code and state and local codes

and ordinances. It is mandatory that a ground connection be

made using a conductor or appropriate metal underground

water pipe or a ground lead in the service panel.

When installing a pump with a 3-prong

grounding plug do not remove round grounding prong

since it must be plugged into a grounded receptacle to

assure proper grounding.

Direct wiring instructions can be found on the inside cover of

your pressure switch.

Step 6. Prime the Pump

A. Remove the manual regulator.

B. Pour water into the pump case until it flows freely out

of the priming hole without air bubbles.

C. Turn the regulator adjusting screw counter-clockwise

until stem travel stops, or regulator poppet is near

valve bushing end. Replace regulator.

D. Turn the adjusting screw in a clockwise direction until

it is all the way in.

E. Open faucets on the downstream side of the pressure

tank to bleed off air.

F. Turn power on. Start pump. The pump should start

showing pressure on the pressure gauge.

G. To adjust the regulator, slowly turn the adjusting screw

in a counter-clockwise direction until the pressure

gauge fluctuates rapidly or the pump becomes noisy.

At this point, turn the screw clockwise until gauge

pressure holds steady.

H. Close all faucets on the downstream side. Sufficient

pressure should build up and shut the pump off.

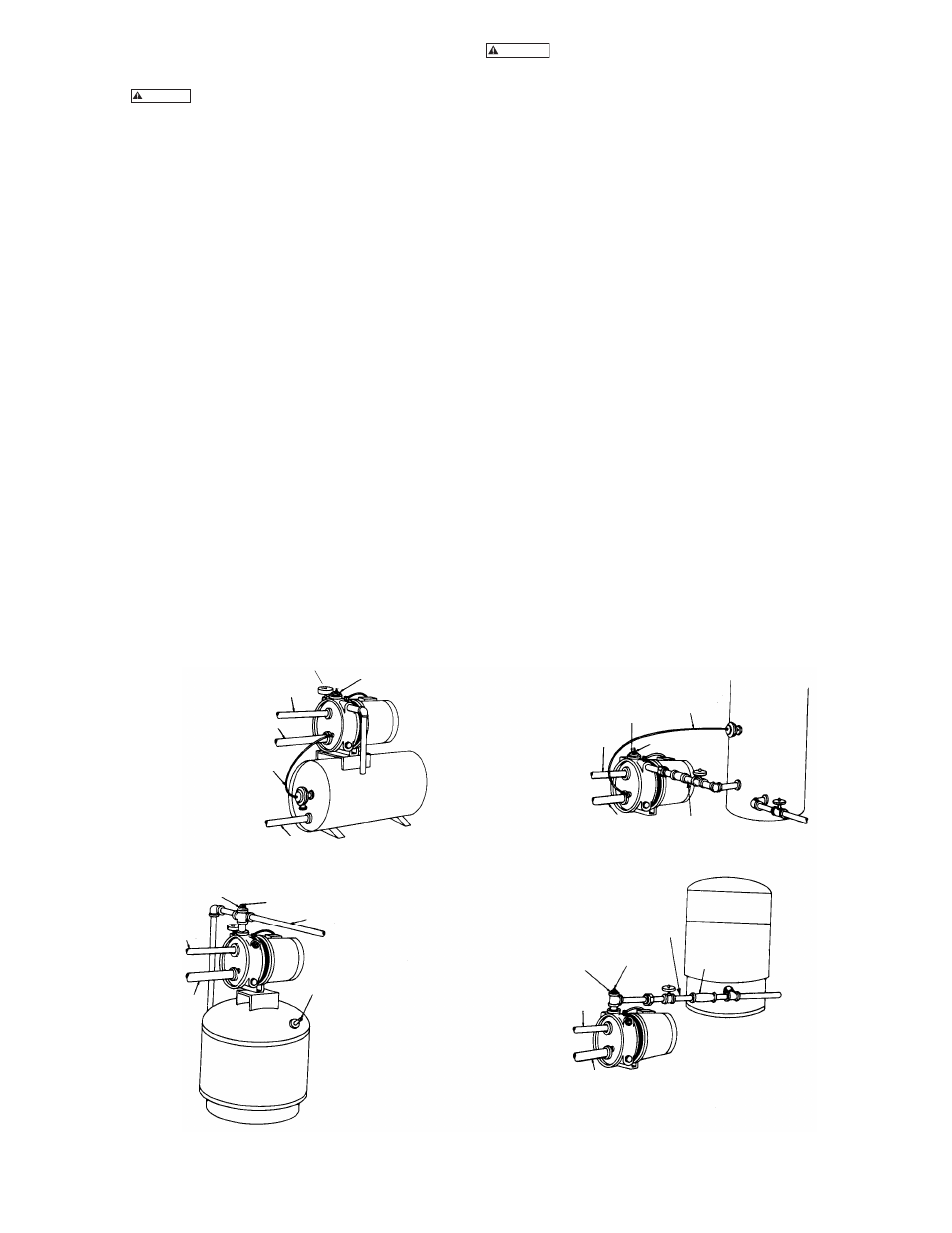

DEEP WELL JET PUMP SYSTEM LAYOUTS

PRESSURE GAUGE

DRIVE PIPE

MANUAL REGULATOR

SUCTION PIPE

AIR VOLUME CONTROL LINE

SERVICE LINE

"T" MANUAL REGU-

LATING VALVE

DRIVE PIPE

SUCTION PIPE

PRIME HERE

SERVICE LINE

AIR CHARGING

VALVE

MANUAL REGULATOR

AIR VOLUME

CONTROL LINE

MANUAL REGULATOR

DRIVE PIPE

PRIME HERE

SUCTION PIPE

SERVICE LINE

SERVICE LINE

ISOLATOR

HOSE

PRIME HERE

"T" MANUAL

REGULATING

VALVE

DRIVE PIPE

WARNING

WARNING

FIGURE 10

SUCTION PIPE