Standard pressure tank, Adjusting pre-charged tank to system requirements – Xylem IM125 R02 RJA & RJDS Quick Set User Manual

Page 10

10

Section 7 Pressure Tanks

and Piping

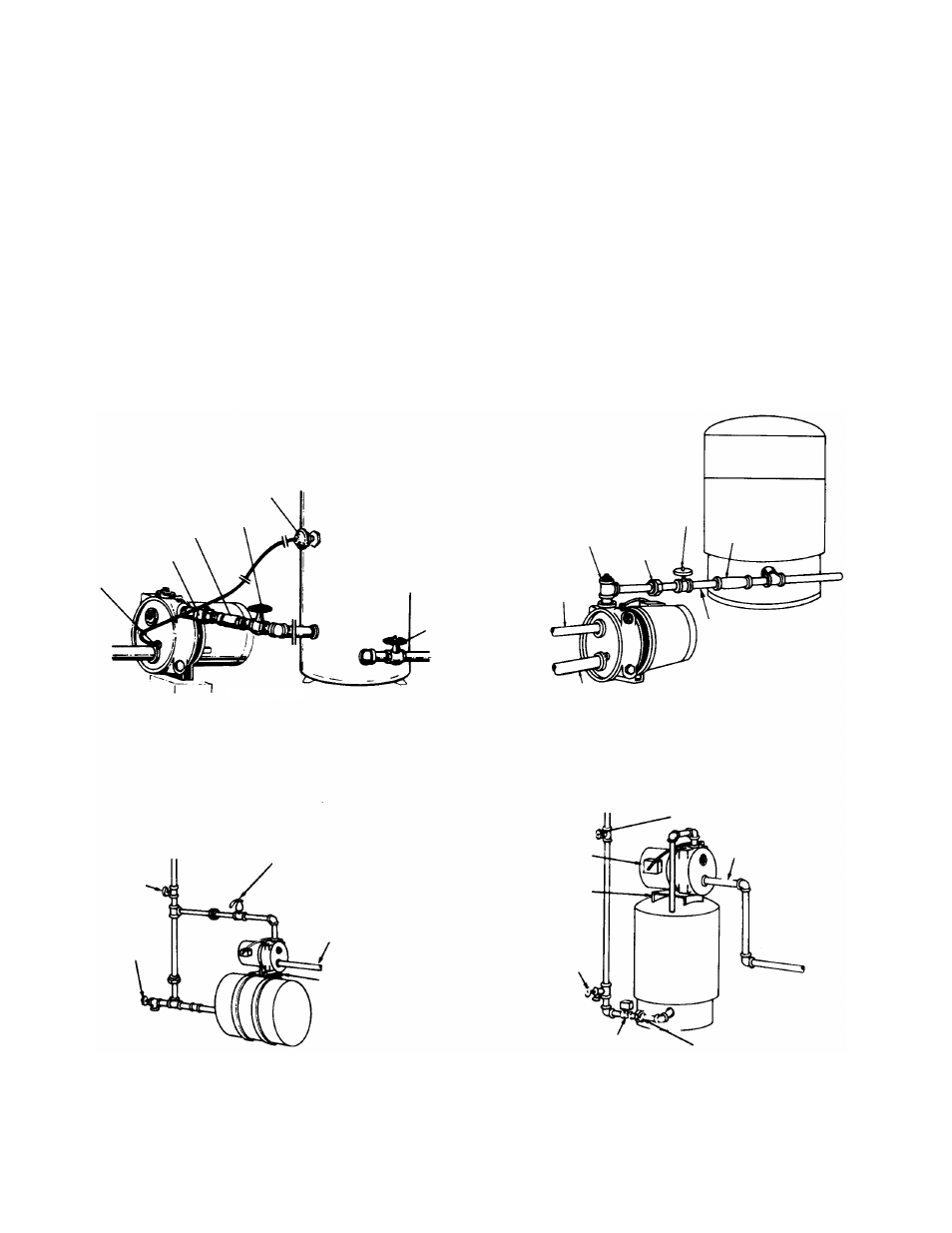

Standard Pressure Tank

When a pump is used with a standard pressure tank, it must

be connected to the tank using standard fittings. A rubber

isolator hose should be connected between the pump and

the tank to reduce noise and vibration transmission. Set

the tank on bricks to avoid condensation beneath the tank.

Install a union and a gate valve between the pump and tank

for servicing. Install an air volume control in the tank tapping

and connect ¼" tubing to the pump. (Figure 12.)

Replacing a Standard Tank With a

Pre-Charged Air Tank

Many times a defective steel tank must be replaced with a

pre-charged air tank to provide effective system protection.

Figure 13 should be followed for correct connection to the

system.

Because a pre-charged air tank is precharged with air, it will

always occupy less space than a standard tank for similar

amounts of pressurized water. Be sure to plug the air port on

a jet pump, as it is no longer necessary to supply air to the

tank.

Adjusting Pre-Charged Tank To

System Requirements

Pre-charged tanks are shipped with a standard precharge of

38 PSI. The precharge should be adjusted according to the

installation instructions packed with the tank.

AIR VOLUME CONTROL

GATE VALVE

ISOLATOR HOSE

UNION

STD. GALVANIZED

PRESSURE TANK

VALVE

"T" MANUAL

REGULATING

VALVE

UNION

GATE VALVE

PRE-CHARGED

AIR TANK

ISOLATOR

HOSE SERVICE

LINE

SUCTION

PIPE

DRIVE PIPE

TO SYSTEM

SHUT-OFF

VALVE

RELIEF

VALVE

SUCTION

PIPE

PUMP STAND

DRAIN

TO SYSTEM

SHUT-OFF VALVE

PRESSURE

SWITCH

PUMP STAND

DRAIN

OPTIONAL

LOCATION

FOR PRESSURE

SWITCH

UNION

PRE-CHARGED AIR TANK

STANDARD PRESSURE TANK

FIGURE 14

FIGURE 15

FIGURE 13

FIGURE 12

CENTRIPRO

TANK

CENTRIPRO

TANK

SUCTION PIPE

AIR VOLUME

CONTROL

CONNECTION