Corrective maintenance, Preventive maintenance procedures thrust pot – Xylem A-C Fire Pump – Vertical Turbine Fire Pump AC8499 User Manual

Page 18

18

Corrective Maintenance

Corrective maintenance procedures include troubleshooting for isolating and remedying malfunctions of the pump and its com-

ponents during operation.

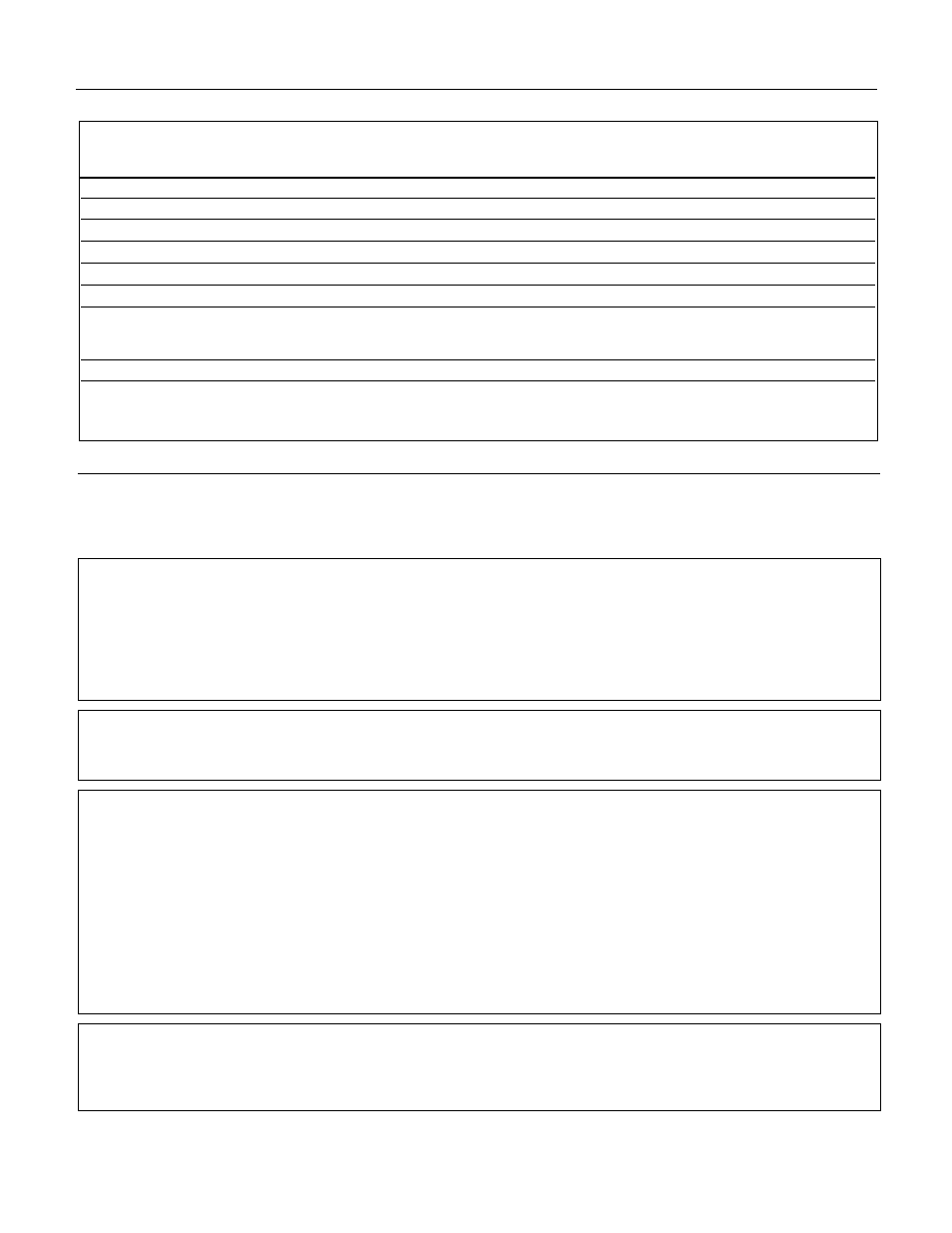

TROUBLE

PROBABLE CAUSE

REMEDY

1. Pump does not start

A. Electrical circuit open or not

Check circuit and correct.

completed

B. Steam turbine not receiving

Make sure that turbine receives

steam pressure

full steam pressure.

C. Impellers binding against bowl

Reset impeller adjustment

D. Low voltage supplied to

Check whether driver wiring is

electric driver

correct and receives full voltage.

E. Defective motor

Consult factory.

2. No liquid delivered

A. Insufficient submergence of

Check for adequate submergence.

bowl assembly

B. Obstruction in liquid passage

Pull pump, inspect impeller and bowl.

3. Not enough liquid

A. Speed is too low

Check if driver is directly across

delivered

the line and receiving full voltage.

B. Wrong rotation

Check for CCW rotation when

viewed from above. Check

engagement of motor coupling.

C. Total pump head is too high

Check pipe friction losses.

Larger piping may correct condition.

D. Partial obstruction in liquid

See step 2-B.

passages

E. Cavitation

Insufficient NPSH available.

F. Impellers adjusted too high

See pages 3-B.

4. Not enough pressure

A. Speed is too low

See step 1-B.

B. Obstruction in liquid

Pull pump and inspect impeller

passages

and bowl passages.

C. Wrong rotation

See step 3-B.

TIME INTERVAL

PROCEDURE

(in operating hours)

Clean dirt, oil and grease from driver and discharge head.

As required.

Clean driver ventilation passage to prevent overheating.

As required.

Change lubrication in gear drive.

2,000 or once a year

Change lubrication in thrust pot.

See Section 13

Tighten all loose bolts, and check for excessive vibration.

As required.

If packing is grease lubricated, add as required.

100

Check that there is some leakage through stuffing box while

As required.

pump is in operation. Do not tighten gland nuts unless necessary.

Refer to Page 17 for tightening requirements.

Maintain a liquid film of lubrication between the seal rubbing faces.

As required.

Regrease motor bearings:

1800 RPM and above

1,000

Below 1800 RPM

2,000

Preventive Maintenance Procedures Thrust Pot