Installing the driver – Xylem A-C Fire Pump – Vertical Turbine Fire Pump AC8499 User Manual

Page 14

INSTALLATION OF A HOLLOW SHAFT DRIVER

This refers to either VHS type electric motors or hollow shaft

type gear drives.A small paragraph will be devoted to combi-

nation electric motor and right angle gear drives.

NOTE

: When pump is supplied with a thrust pot, do not

secure driver to discharge head until after the thrust pot and

flexible coupling are installed.

1. The driveshaft projecting through the quill or hollow-shaft

of the driver is separate from the pump shaft and con-

nected to same by a rigid flanged coupling or threaded

coupling.

2. Driver support. When a driver support is furnished and not

installed, proceed as follows:

A. Hoist driver support, inspect the mounting surfaces,

register, and clean these surfaces thoroughly.

B. Install driver support on discharge head and secure with

capscrews provided.

3. Attach a sling to the lifting lugs of driver, hoist motor,

inspect the mounting surface, register, and shaft exten-

sion, and clean these surfaces thoroughly. If any burrs are

found, remove burrs with a smooth mill file, cleaning thor-

oughly afterward.

4. Orient the motor conduit box in the required position. Align

the motor mounting holes with the mating tapped holes on

the discharge head. Lower the motor until the registers

engage and the motor rests on the discharge head. Secure

motor with capscrews provided.

5. On drivers having a non-reverse ratchet or pins, manually

turn the driver shaft clockwise viewed from the top until the

non-reverse ratchet or pins fully engage.

6. Lubricate motor bearings in accordance with instructions

given on lubrication plate attached to the motor case.

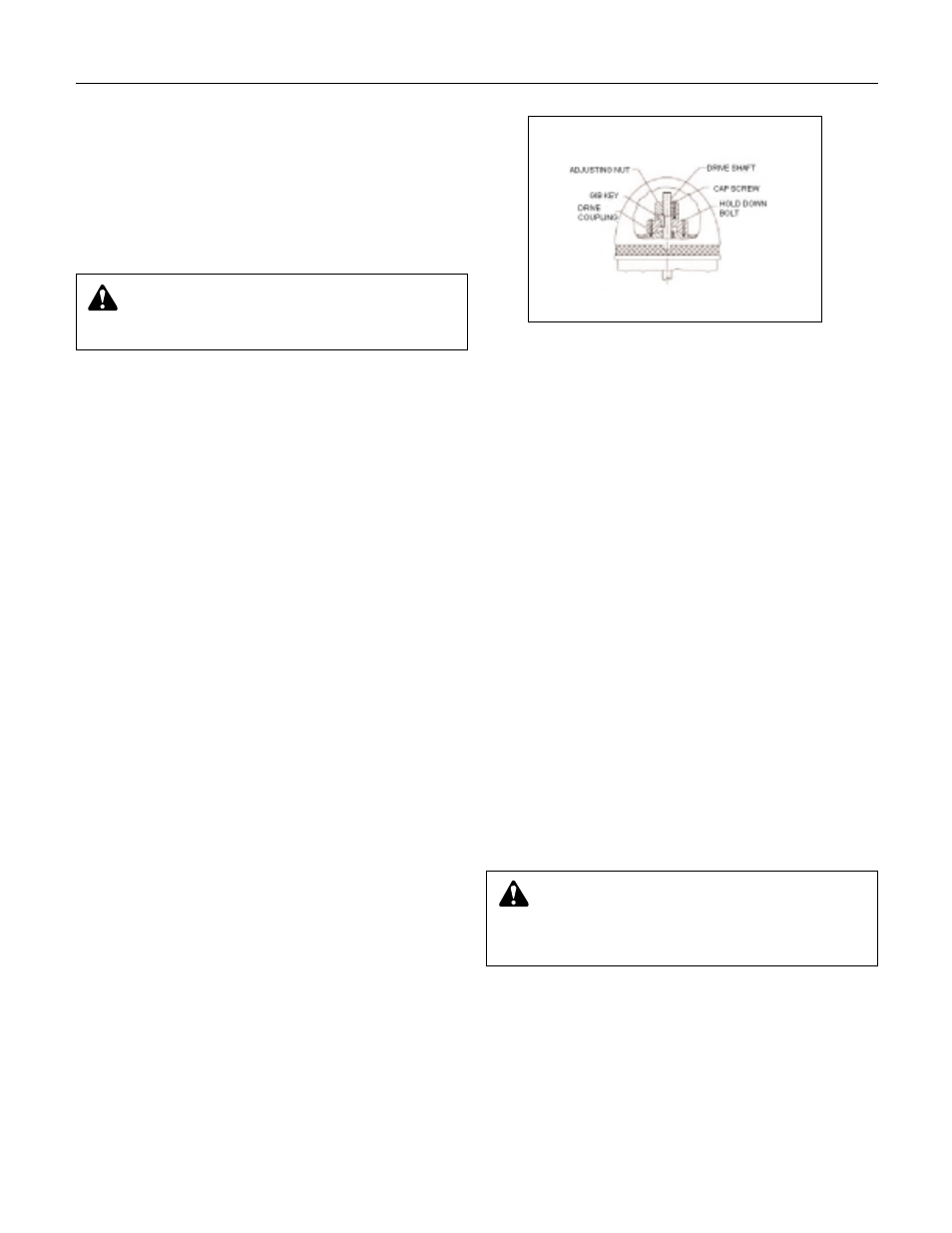

7. The driving mechanism of all hollow shaft drives is shown

on Figure 6. The driveshaft (606) extends up through the

quill or hollow shaft of the motor (or gear drive) and is held

in place by an adjusting nut (604), which not only carries

all the static and hydraulic thrust of the impellers and

shaft but also provides the adjustment for the impeller

clearances.

8. After lowering and orienting the motor and/or gear drive as

explained above, remove the drive coupling and the hold

down bolts as shown in Figure 6.

9.

Screw the adjusting nut (604) loosely onto the end of drive-

shaft (606). Clean thoroughly and attach a light line below

the nut. Lower the driveshaft through the motor quill

shaft. Examine closely for dirt or burrs between shaft

ends.

10.

Apply a suitable thread compound to the driveshaft

threaded coupling. Thread the driveshaft into the threaded

coupling and tighten.

COMPLETION OF INSTALLATION OF A

HOLLOW SHAFT DRIVER

1.

Remove lifting sling and see if driveshaft centers inside

the motor quill shaft within 0.06" (1.5mm). If it does not,

misalignment is indicated.

2.

Any driveshaft misalignment with driver quill shaft could

be caused by a bent driveshaft, burrs, or foreign matter

between shaft ends or any of the mounting flanges:

motor to mount, mount to discharge head, discharge

head mounting to plate or the plate itself could be out of

level. If the latter, shimming between it and discharge

head base, will correct it. Also, check concentricity of

motor to motor stand to discharge head.

3.

With the motor in place and the driveshaft projecting

through the motor quill shaft, connect up the electricity

and check motor rotation. This should be counter-

clockwise when viewed from the top. See arrow on pump

name plate. If motor does not rotate counter-clockwise,

you can change the rotation by interchanging any two

leads (for three phase only, for single phase motors see

motor manufacturer’s instructions.)

4.

Install motor drive coupling, inserting the ratchet pins if a

non-reverse ratchet is used. Match the coupling lugs with

corresponding holes in motor. Tighten down hold down

bolts evenly, making sure drive coupling is properly

seated in the register fit.

14

Installing the Driver

Figure 6

WARNING:

Do not work under a heavy suspended

object unless there is a positive support and safe-

guards which will protect personnel should a hoist or sling

fail.

CAUTION:

Never check motor rotation with the

drive coupling in place. The bore clearance between

the drive coupling and the pump shaft O.D. is so close that

should the motor spin with this shaft stationary, galling and

locking together is very likely to take place.