Ap5100, Applications information – Diodes AP5100 User Manual

Page 8

AP5100

1.2A STEP-DOWN CONVERTER with 1.4MHz SWITCHING

FREQUENCY

AP5100

Document number: DS32130 Rev. 3 - 2

8 of 12

April 2012

© Diodes Incorporated

Applications Information

(cont.)

Setting the Output Voltage

(cont.)

Choose the inductor ripple current to be 30% of the

maximum load current. The maximum inductor peak

current is calculated from:

2

L

ΔI

LOAD

I

L(MAX)

I

+

=

Equation 3

Peak current determines the required saturation current

rating, which influences the size of the inductor. Saturating

the inductor decreases the converter efficiency while

increasing the temperatures of the inductor, the MOSFET

and the diode. Hence choosing an inductor with

appropriate saturation current rating is important.

A 1µH to 10µH inductor with a DC current rating of at least

25% percent higher than the maximum load current is

recommended for most applications.

For highest efficiency, the inductor’s DC resistance should

be less than 200m

Ω. Use a larger inductance for

improved efficiency under light load conditions.

Input Capacitor

The input capacitor reduces the surge current drawn from

the input supply and the switching noise from the device.

The input capacitor has to sustain the ripple current

produced during the on time on the upper MOSFET. It

must hence have a low ESR to minimize the losses.

Due to large dI/dt through the input capacitors, electrolytic

or ceramics should be used. If a tantalum must be used, it

must be surge protected. Otherwise, capacitor failure

could occur. For most applications, a 4.7µF ceramic

capacitor is sufficient.

Output Capacitor

The output capacitor keeps the output voltage ripple small,

ensures feedback loop stability and reduces the overshoot

of the output voltage. The output capacitor is a basic

component for the fast response of the power supply. In

fact, during load transient, for the first few microseconds it

supplies the current to the load. The converter recognizes

the load transient and sets the duty cycle to maximum, but

the current slope is limited by the inductor value.

Maximum capacitance required can be calculated from the

following equation:

2

OUT

V

2

)

OUT

V

V

(

Δ

2

)

2

inductor

ΔI

OUT

L(I

o

C

−

+

+

=

Equation 4

Where

ΔV

is the maximum output voltage overshoot.

Where

inductor

ΔI

is the inductor ripple current.

ESR of the output capacitor dominates the output voltage

ripple. The amount of ripple can be calculated from the

equation below:

ESR

inductor

ΔI

capacitor

Vout

×

=

An output capacitor with ample capacitance and low ESR

is the best option. For most applications, a 22µF ceramic

capacitor will be sufficient.

External Diode

The external diode’s forward current must not exceed the

maximum output current. Since power dissipation is a

critical factor when choosing a diode, it can be calculated

from the equation below:

0.3V

out

I

)

IN

V

OUT

V

(1

diode

P

Ч

Ч

−

=

Equation 5

Note: 0.3V is the voltage drop across the schottky diode. A

diode that can withstand this power dissipation must be

chosen.

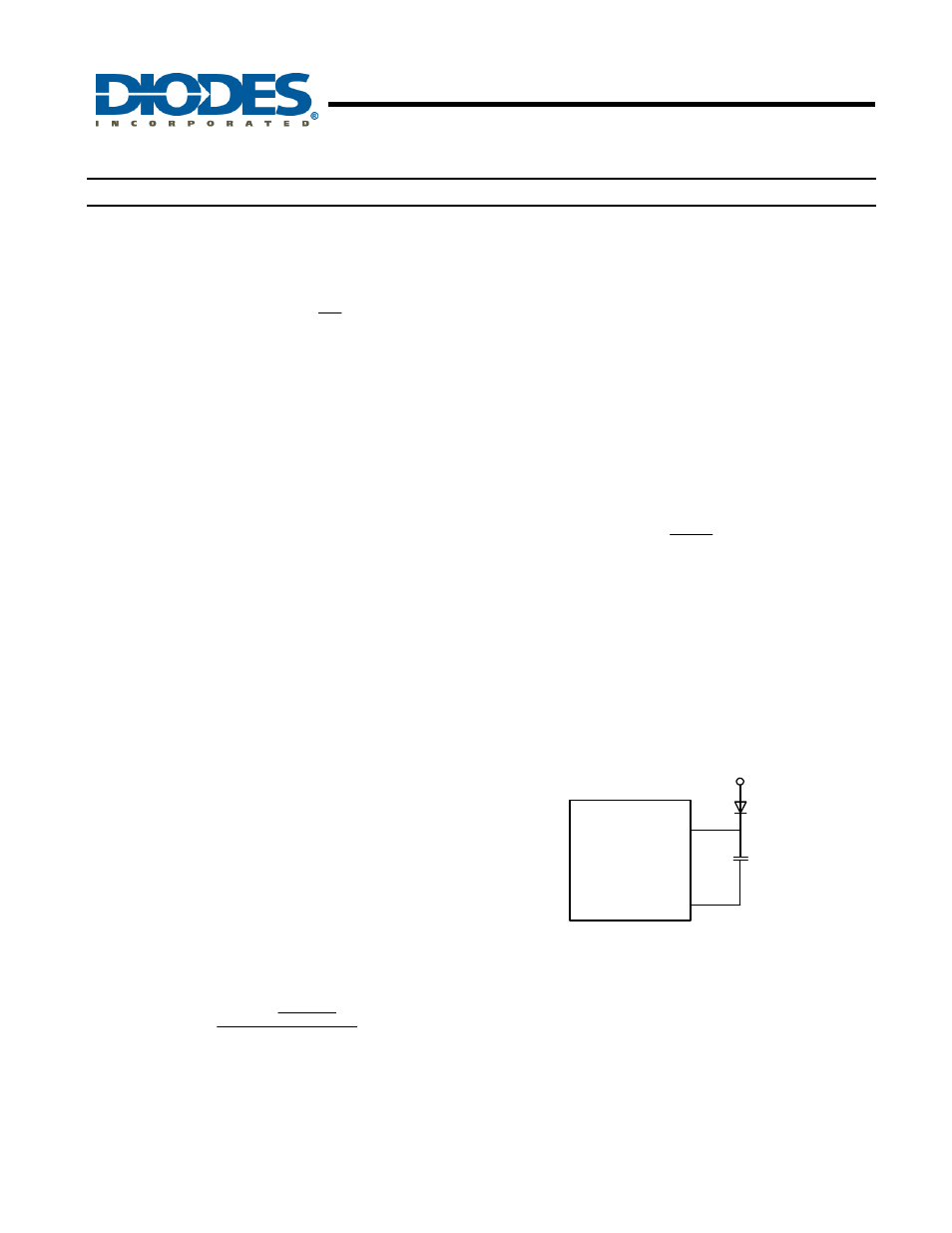

External Bootstrap Diode

It is recommended that an external bootstrap diode be

added when the input voltage is no greater than 5V or the

5V rail is available in the system. This helps improve the

efficiency of the regulator. The bootstrap diode can be a

low cost one such as IN4148 or BAT54.

AP5100

BST

SW

10nF

BOOST

DIODE

5V

1

6

Figure 6. External Bootstrap Diode

Under Voltage Lockout (UVLO)

Under Voltage Lockout is implemented to prevent the IC

malfunction from insufficient input voltages. For power-up,

the AP5100 must be enabled and the input voltage must

be higher than the UVLO rising threshold (4.0 V typ).

When the input voltage falls below the UVLO falling

threshold (UVLO rising threshold – UVLO hysteresis), the

AP5100 will latch an under voltage fault. In this event, the

output will fall low. To resume

normal operation, the

AP5100 must be pulled above the UVLO rising threshold.