New prod uc t zxbm5210 – Diodes ZXBM5210 User Manual

Page 6

ZXBM5210

Document number: DS36765 Rev. 1 - 2

6 of 17

December 2013

© Diodes Incorporated

NEW PROD

UC

T

ZXBM5210

Application Note

(cont.)

Motor Speed Control with DC Voltage on V

REF

Pin

Motor speed can be controlled by adjusting the DC voltage into the V

REF

pin. The output drive PWM duty ratio is defined by the ratio of the V

REF

voltage to the supply V

DD

voltage.

In V

REF

speed control mode, FWD and REV pins are only used for direction control and therefore high frequency PWM control signal should not

be applied to the FWD and REV pins. If repetitive direction changes required, it is recommended to keep direction change frequency of below

400Hz.

The speed and direction control is given by:

FWD REV V

REF

OUT1 OUT2

Operating mode

L

L

x

Open

Open

Standby mode – All switches are off

H L V

DD

H L

Forward mode – Current flows from OUT1 to OUT2; 100% duty

H L

3V to V

DD

H L

Forward mode – Current flows from OUT1 to OUT2; V

REF

duty control

L H V

DD

L H

Reverse mode – Current flows from OUT2 to OUT1; 100% duty

L H

3V to V

DD

L H

Reverse mode – Current flows from OUT2 to OUT1; V

REF

duty control

H

H

x

L

L

Brake mode – Short circuit brake with low side switches on

Motor Speed Control with a PWM Input Signal

Motor speed can be controlled by adjusting the duty cycle of the PWM speed control signal into the FWD or REV while keeping the V

DD

pin at

the nominal motor voltage. In this mode the input voltage on the V

REF

pin must be greater than or equal to V

DD

.

In PWM speed control mode the high side switches S1 and S3 are kept fixed while the low side switches S2 or S4 are switched. In the forward

mode, S1 is kept switched on, S2 is switched in accordance with the PWM signal and S3 and S4 are switched off. In reverse mode, S3 is

switched on, S4 is switched in accordance with the PWM signal and S1 and S2 are switched off.

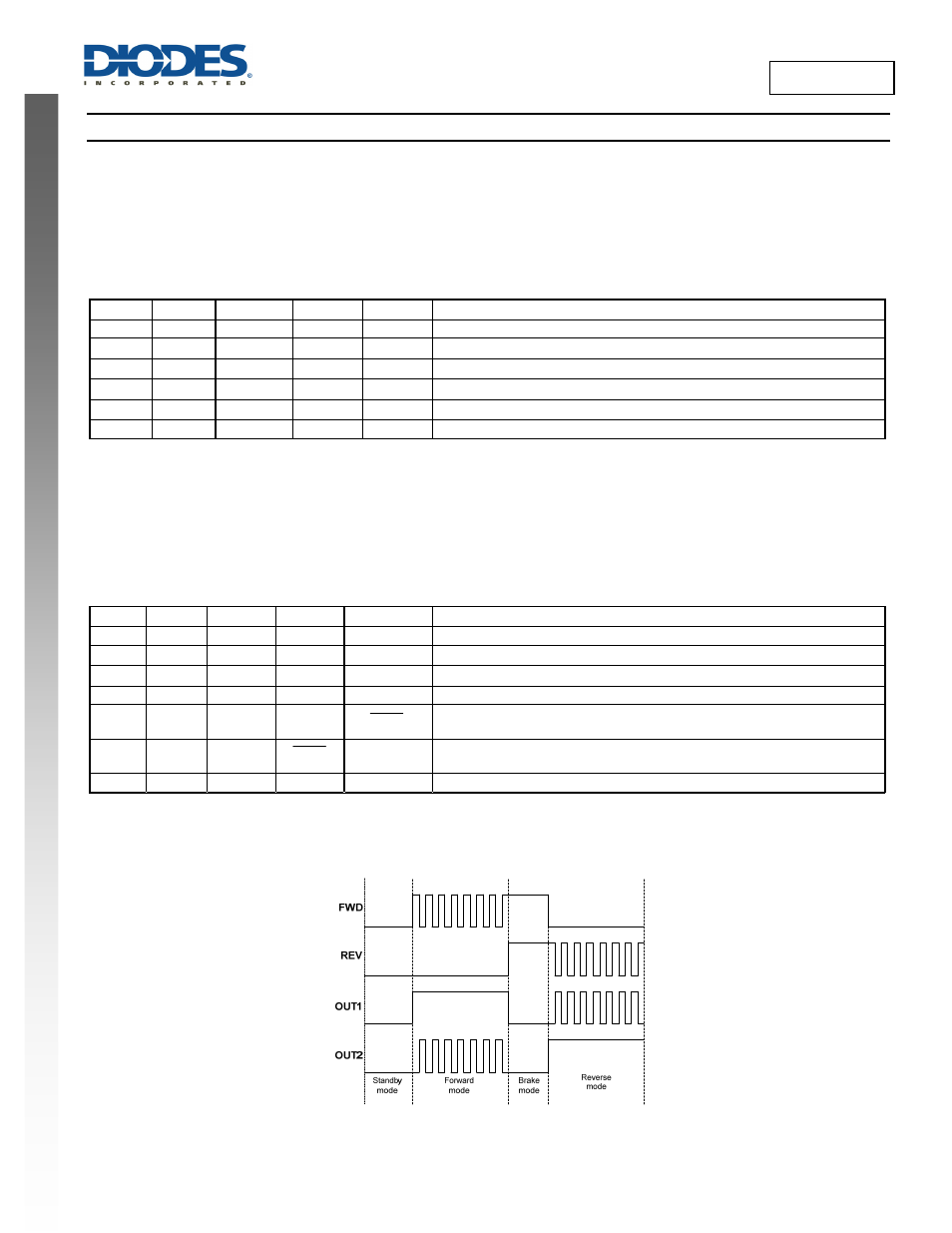

The speed and direction control is given by:

FWD REV V

REF

OUT1 OUT2

Operating

mode

L

L

x

Open

Open

Standby mode – All switches are off

H L V

DD

H L

Forward mode – Current flows from OUT1 to OUT2; 100% duty

L H V

DD

L H

Reverse mode – Current flows from OUT2 to OUT1; 100% duty

H

H

x

L

L

Brake mode – Short circuit brake with low side switches on

PWM L V

DD

H PWM

Forward mode – Current flows from OUT1 to OUT2;

PWM control mode

L PWM V

DD

PWM H

Reverse mode – Current flows from OUT2 to OUT1

PWM control mode

H

H

x

L

L

Brake mode – Short circuit brake with low side switches on

The motor speed is proportional to the input PWM signal duty. For example, for a 12V motor the V

DD

pin is maintained at 12V while varying the

PWM control signal duty to adjust the motor speed linearly. The timing diagram below shows the output O1 and O2 in relation to PWM speed

control signal at PWM pin.

Frequency of PWM speed control signal can be between 8kHz to 100kHz. Recommended typical PWM signal frequency is 25kHz to keep

switching frequency away from the audible band.