Analytical Industries GPR-2500 A Oxygen Analyzer User Manual

Page 13

13

Gas Connections:

The GPR-2500A with its standard flow through configuration is designed for positive pressure samples and requires

connections for incoming sample and outgoing vent lines. The user is responsible for calibration gases and the

required components, see below.

Flow rates of 1-5 SCFH cause no appreciable change in the oxygen reading. However, flow rates above 5 SCFH

generate backpressure and erroneous oxygen readings because the diameter of the integral tubing cannot

evacuate the sample gas at the higher flow rate. A flow indicator with an integral metering valve upstream of the

sensor is recommended as a means of controlling the flow rate of the sample gas. A flow rate of 2 SCFH or 1 liter

per minute is recommended for optimum performance.

Caution: Do not place your finger over the vent (it pressurizes the sensor) to test the flow indicator when gas is

flowing to the sensor. Removing your finger (the restriction) generates a vacuum on the sensor and may damage

the sensor (voiding the sensor warranty).

Procedure:

1. Caution: Do not change the factory setting until instructed to do in this manual.

2. Designate one of the bulkhead tube fittings as the VENT and the other SAMPLE.

3. Regulate the pressure as described in Pressure and Flow above.

4. Connect a 1/8” vent line to the compression fitting to be used for venting the sample.

5. Connect a 1/8” ZERO, SPAN or SAMPLE line to the fitting designated SAMPLE.

6. If equipped with optional fittings and/or sample system, connect the ZERO and SPAN gas lines.

7. Allow gas to flow through the transmitters and set the flow rate to 2 SCFH.

Integral Oxygen Sensor:

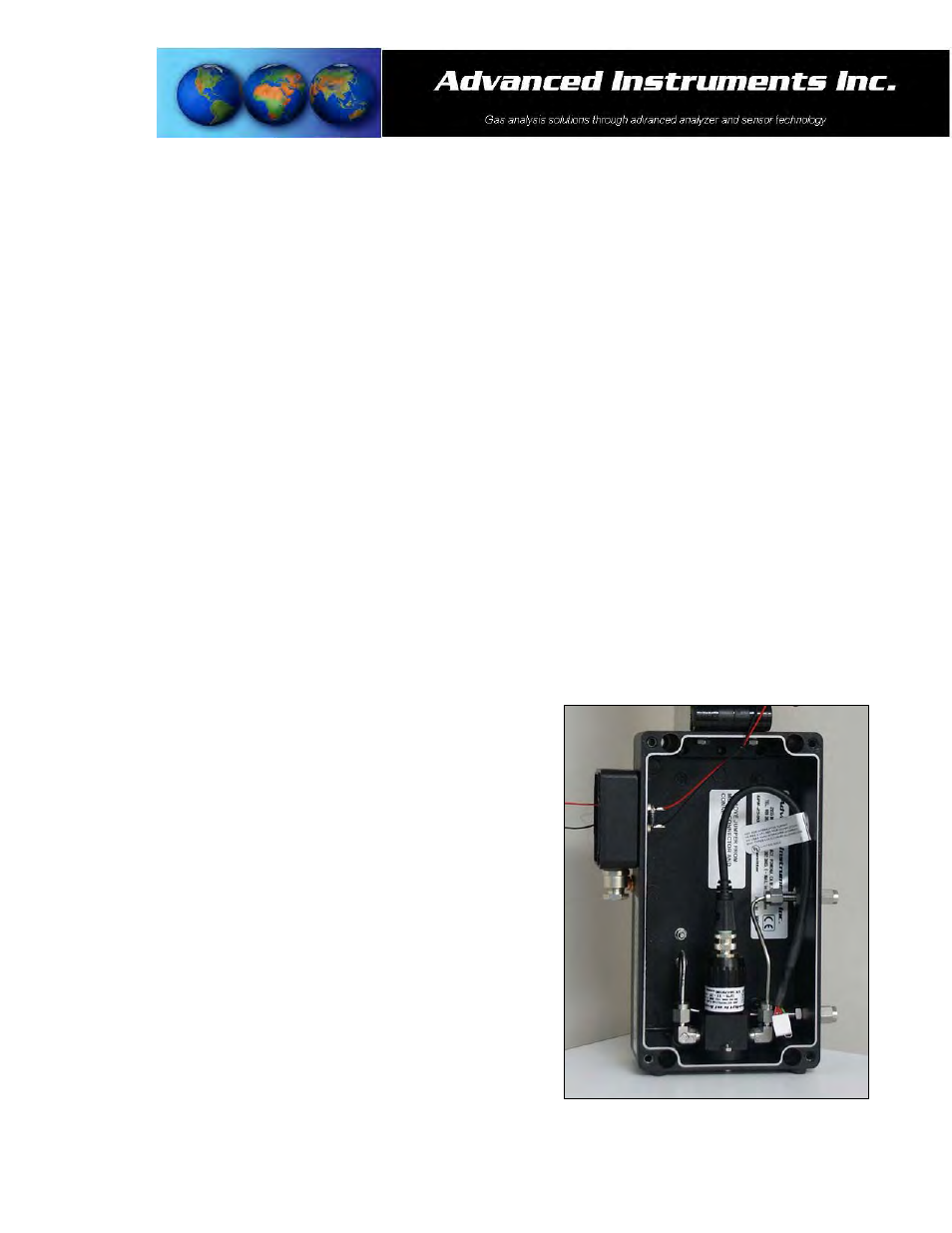

1. Remove the four (4) screws securing the top section of the

enclosure, set them aside for reinstallation and raise the hinged

top section 180º until it locks in place.

2. Caution: Do not remove or discard the gaskets from either the

enclosure or junction box. Failure to reinstall either gasket will

void the NEMA 4 rating and RFI protection.

3. The transmitters design provides protection from RFI that is

maintained by leaving specific mating areas of the enclosure

unpainted to maintain conductivity the gasket, top and bottom

sections of the enclosure. These unpainted areas are protected

by gaskets and contribute to maintaining the NEMA 4 rating. Do

not paint these areas. Painting will negate the RFI protection.

4. Remove the oxygen sensor from the bag.

5. Screw the oxygen sensor into the sensor flow housing,

equipped with elbows and tubing, finger tighten plus one half

(1/2) turn to ensure a good seal from the o-ring affixed to the

sensor.

6. Remove the shorting device (looped wire) from the receptacle

located at the rear of the sensor. Minimize the time the sensor

is exposed to ambient air.