Advanced instruments inc, Mounting the analyzer – Analytical Industries GPR-1600 MS Series PPB Oxygen Analyzer User Manual

Page 13

Advanced Instruments Inc.

13

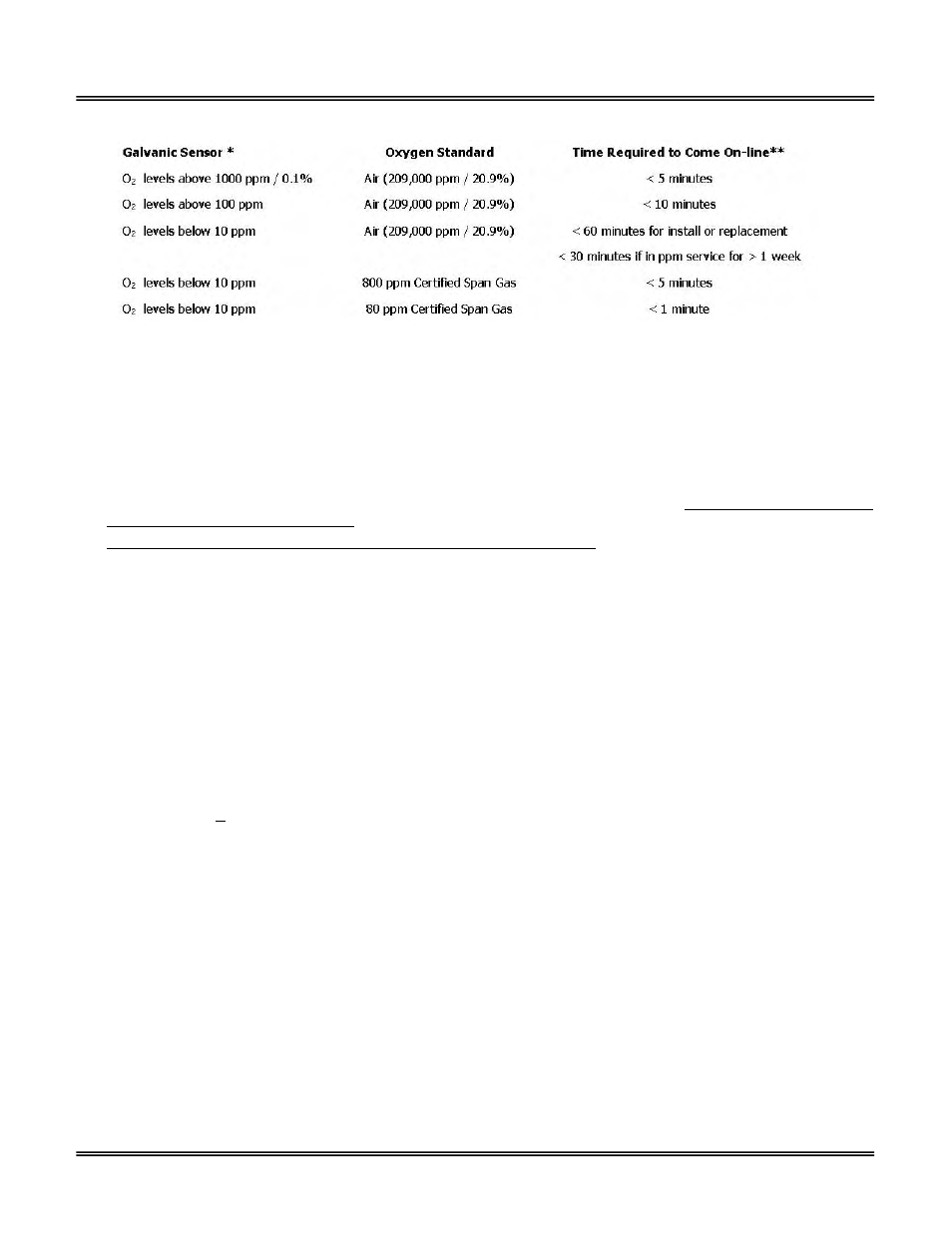

* Refer to analyzer specifications for comparable data on the Pico-Ion UHP and MS oxygen sensors.

Recommendations General:

¾ The interval between SPAN CALIBRATION should not exceed three (3) months.

¾ Always calibrate at the same temperature and pressure of the sample gas stream.

¾ If a ZERO CALIBRATION adjustment is made during initial installation, it is normally not required again until the sample

system connections are modified or a new oxygen sensor is installed. Therefore the DEFAULT ZERO function is

recommended only when performing a ZERO CALIBRATION and during troubleshooting and should not be repeated before

routine subsequent SPAN CALIBRATION.

¾ If a ZERO CALIBRATION adjustment has NOT been made as described above, perform the DEFAULT ZERO and DEFAULT

SPAN functions when troubleshooting an analyzer and before SPAN CALIBRATION.

¾ Caution: Prematurely initiating the SPAN CALIBRATION function before the analyzer reading has stabilized can result in

erroneous readings. This is especially true when installing a new sensor that must adjust to the difference in oxygen

concentrations. It should take about 2 minutes for the sensor to equilibrate in ambient air from storage packaging.

¾ For 'optimum SPAN CALIBRATION accuracy' use a span gas approximating 80% of the full scale range higher range than

the range of interest (normal use) to achieve the effect of “narrowing the error” by moving downscale as illustrated by

Graph A in the Accuracy & Calibration section.

¾ SPAN CALIBRATION with a span gas approximating 5-10% of the full scale range near the expected oxygen concentration

of the sample gas is acceptable but less accurate than ‘optimum SPAN CALIBRATION accuracy’ method recommended – the

method usually depends on the gas available.

¾ SPAN CALIBRATION at the same 5-10% of the full scale range for measurements at the higher end of the range (example:

calibrating an Oxygen Purity Analyzer in air at 20.9% oxygen with the intention of measuring oxygen levels of 50-100%)

results in the effect of “expanding the error” by moving upscale as illustrated by Graph A and Example 1 in the Accuracy &

Calibration section above and is not recommended. Of course the user can always elect at his discretion to accept an

accuracy error of +2-3% of full scale range if no other span gas is available.

Recommendations Air Calibration:

¾ Do not calibrate an analyzer employing the Pico-Ion UHP or MS sensor, or, an oxygen purity sensor with air.

Mounting the Analyzer

The standard GPR-1600MS is designed to be panel mounted and requires a cutout that accommodates the enclosure and 4

mounting bolts. The design also lends itself to 19” rack mounting with an optional bezel or wall mount enclosures as illustrated

below.

Procedure:

1. The GPR-1600MS is designed for panel mounting directly to any flat vertical surface, wall or bulkhead plate with the

appropriate cut out and four ¼” diameter holes for insertion of the mounting studs located on the back side of the front

panel.

2. When mounting the analyzer position it approximately 5 feet off the floor for viewing purposes and allow sufficient room for

access to the terminal connections at the rear of the enclosure.