Advanced instruments inc. 5 operation – Analytical Industries GPR-3100 Series Oxygen Purity Analyzer User Manual

Page 9

Advanced Instruments Inc.

5 Operation

GPR-3100 Rev 2/05 2

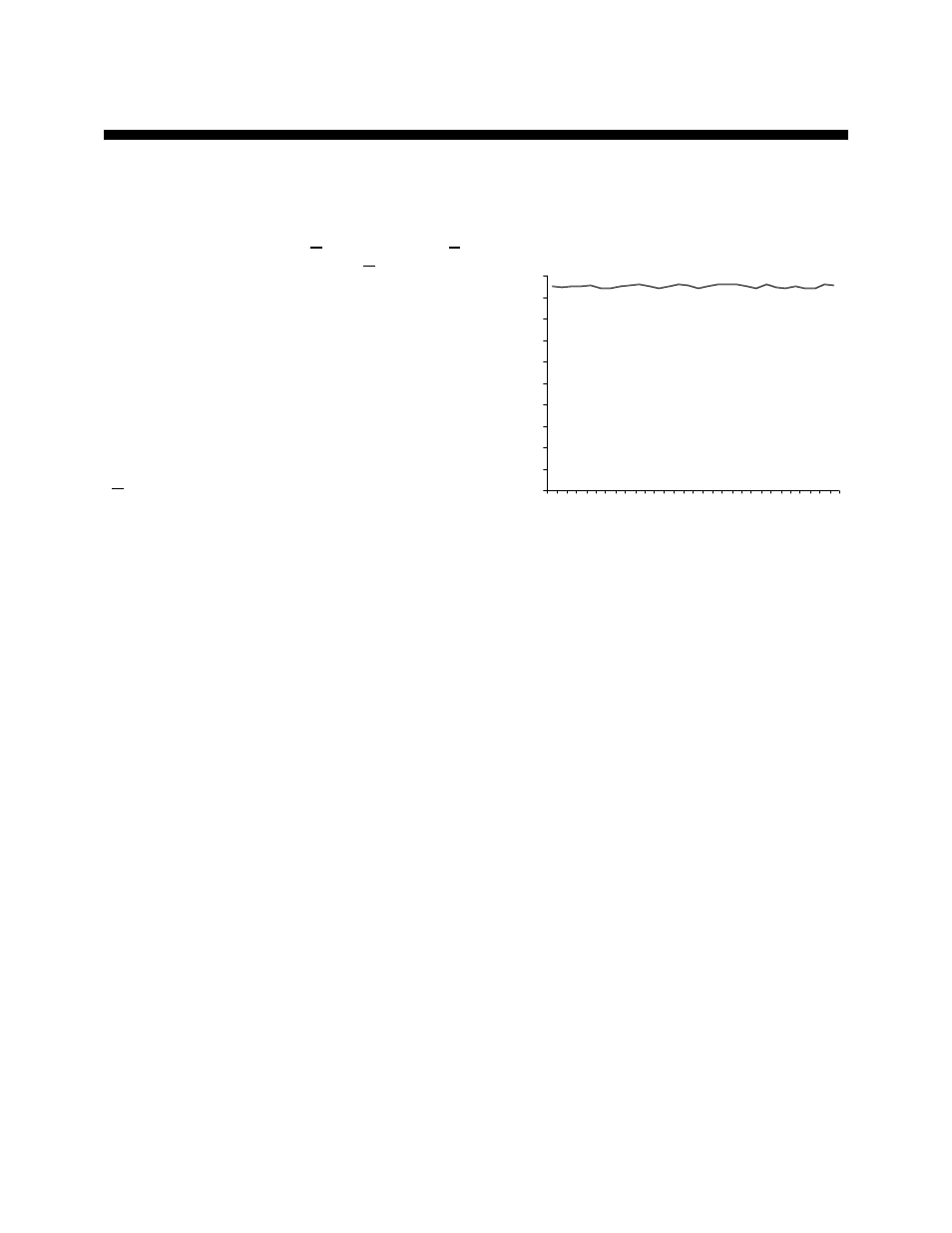

With the sensor and sample gas lines temperature controlled and the signal output of the sensor

compensated for ambient pressure variations it was possible to measure oxygen in the suppressed range

of 90-100% with less than +1% of full scale (+0.1% oxygen) accuracy. The calibration was checked

periodically and found to be within +1% of full

scale over the fourteen month test period

suggesting the interval between calibrations

could be extended to several months.

To demonstrate the stability of the new

analyzer, 99.5% oxygen was introduced

(typically the threshhold for gas manufacturers)

for 30 days and the output plotted as shown at

the right. The resolution of the analyzer’s 4-1/2

digit display is 0.01%.

The maximum variation in the signal output is

+0.1% oxygen over a 24 hour period and is

primarily to the variation in ambient

temperature.

Advanced Sensor Technology Overview:

The sensor function on the same principle and are specific for oxygen. They measure the partial pressure

of oxygen from low ppm to 100% levels in inert gases, gaseous hydrocarbons, helium, hydrogen, mixed

gases, acid gas streams and ambient air.

Oxygen, the fuel for this electrochemical transducer, diffusing into the sensor reacts chemically at the

sensing electrode to produce an electrical current output proportional to the oxygen concentration in the

gas phase. The sensor’s signal output is linear over all ranges and remains virtually constant over its

useful life. The sensor requires no maintenance and is easily and safely replaced at the end of its useful

life.

Proprietary advancements in design and chemistry add significant advantages to an extremely versatile

oxygen sensing technology. Sensors for low ppm analysis recover from air to ppm levels in minutes,

exhibit longer life and reliable quality.

The expected life of our new generation of percentage range sensors now range to five and ten years

with faster response times and greater stability. Another significant development involves expanding the

operating temperature range for percentage range sensors from -30°C to 50°C.

Electronics:

The signal generated by the sensor is processed by state of the art low power micro-processor based

digital circuitry. The first stage amplifies the signal. The second stage eliminates the low frequency noise.

The third stage employs a high frequency filter and compensates for signal output variations caused by

ambient temperature changes. The result is a very stable signal.

Additional features of the micro-processor based electronics include manual or auto ranging, optional

integral sample, span and zero inlet valves for auto-zero and auto-calibration at user specified intervals,

data acquisition and temperature tracking all which can be controlled remotely. Analog outputs, 0-1V and

an isolated 4-20mA, and an USB communication link are provided along with field selectable alarms with

dry relay contacts, power and range identification. An unique algorithm predicts and display a message

indicating a ‘weak sensor’ suggesting the sensor be replaced in the near future.

9 0 .0 0

9 1 .0 0

9 2 .0 0

9 3 .0 0

9 4 .0 0

9 5 .0 0

9 6 .0 0

9 7 .0 0

9 8 .0 0

9 9 .0 0

1 0 0 .0 0

2

5

8

1 1

1 4

1 7

2 0

2 3

2 6

2 9

% O

xy

ge

n

Da y s

30 Day Stability in

99.5% Oxygen

90-100% Suppressed Range