Item: description, Sway control – Pro Series 83660 SWAY CONTROL User Manual

Page 2

ITEM:

DESCRIPTION:

©2009 Cequent Performance Products - Plymouth, MI

Technical Service: (888) 521-0510

83660

SWAY CONTROL

HITCH BALL

BUMPER

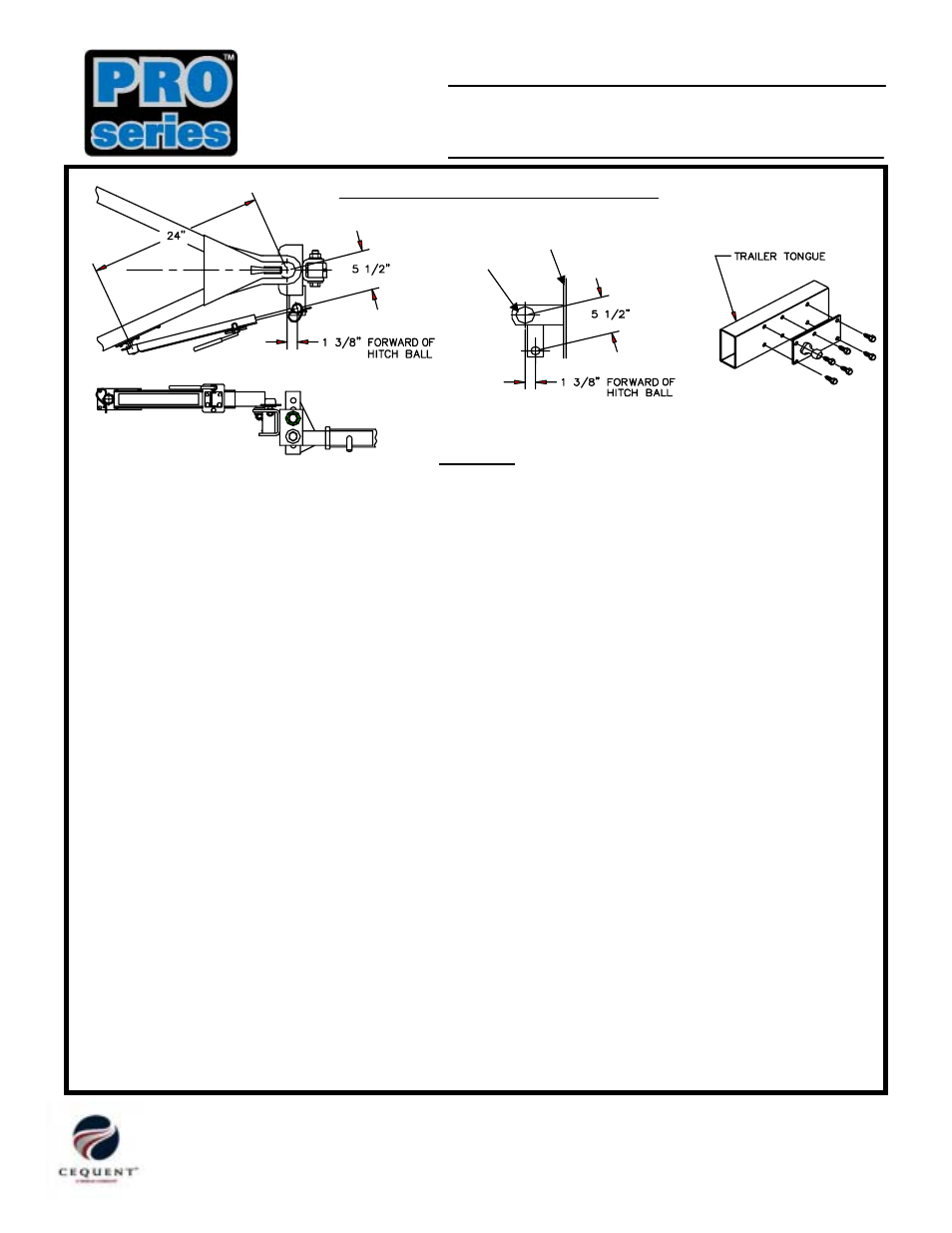

GENERAL SWAY CONTROL MOUNTING DIMENSIONS

FIGURE 2.

1. INSTALLATION

Refer to Figures 1 and 2

a. Connect trailer to tow vehicle. Position vehicle and trailer in a straight line on a level surface.

b. Mount sway control ball (1a) using nut (1b) and lock washer (1c) to hitch as shown in Figure 2 and torque to 100 lb.-ft. If

necessary notch and weld ball mounting bar (4) (sold separately) into position shown.

c. Measure and mark a point on the trailer tongue 24" from the center of the hitch ball as shown in Figure 2.

d. Align the center of the ball of the ball/plate assembly (3) with the mark on the trailer tongue and center punch four hole

locations. Drill four holes using an 11/32 (.343) drill bit for 1/8" (.125) or thicker trailer tongue material, or a 9/32" (.281) drill

bit for thinner material.

e. Position the ball/plate assembly (3) over the drilled holes and drive four of the self tapping screws (2a) through the plate and

into the trailer tongue. Drill the two remaining holes and install the screws.

NOTE: For left hand installation, remove slide bar (6), and reinstall upside down.

2. HOOK-UP

a. Lubricate both balls with a small amount of grease, place socket of slide bar (6) over ball (1) and secure with clip (2b).

Loosen handle (5) until the slide bar can be moved. Extend sway control assembly and place socket over ball on trailer,

secure with other clip (2b).

b. Retighten handle until it stops (handle should be in its original level position).

c. On some installations, damage to the sway control may occur during extremely sharp turning maneuvers. This can be

checked by slowly backing vehicle into a jackknife position while someone is watching. Do not allow slide bar to contract

completely (bottom out) or bumper to contact sway control. If it looks as though contact will be made or the sway control

will bottom out then the sway control must be removed before backing trailer.

3. ADJUSTMENT

a. Trailer configurations and loading, road and weather conditions, towing speed, tire condition and pressure, and center of

gravity of trailer all affect towing. To get maximum benefits from the sway control assembly, a series of road tests should

be taken with the loaded trailer. On subsequent trips increase or decrease tension by turning the adjusting bolt (7) in 1/4

turn increments in the direction shown on the label until the desired control is achieved. For large trailers, it may be

necessary to install a second sway control unit.

b. After about 1000 miles of towing, remove the slide bar from the sway control and clean the friction surfaces with a wire

brush. Repeat this cleaning procedure about every 10,000 miles.

4. UNHOOKING

a. Release tension by turning on/off handle counterclockwise.

b. Remove both clips (2b), remove sway control.

83660N 1-15-09 Rev A

Printed in XXXXX