Instrument storage troubleshooting, Troubleshooting, Instrument storage – Ocean Optics LPC-500CM User Manual

Page 23

4: Maintenance

041-00000-010-02-201106

15

Instrument Storage

Caution

Do not partially dry the LWCC and leave it open to the air. Oxygen in the air may

facilitate the growth of microorganisms inside the device.

To store the instrument, clean the LWCC and then fill it with an 80/20 solution of distilled water/methyl

alcohol. Seal the INFLOW and OUTFLOW ports using either the caps provided or an alternative.

Troubleshooting

The LWCC is a highly sensitive device, and it is extremely important to keep it clean. This is especially

important when working in the ultraviolet range, where unexpected results can often be produced by

contamination of the experimental solution. The high sensitivity of the LWCC may create some problems

that can be easily overcome with care and forethought. Therefore, you may need to develop new skills in

handling both the equipment and the samples being examined.

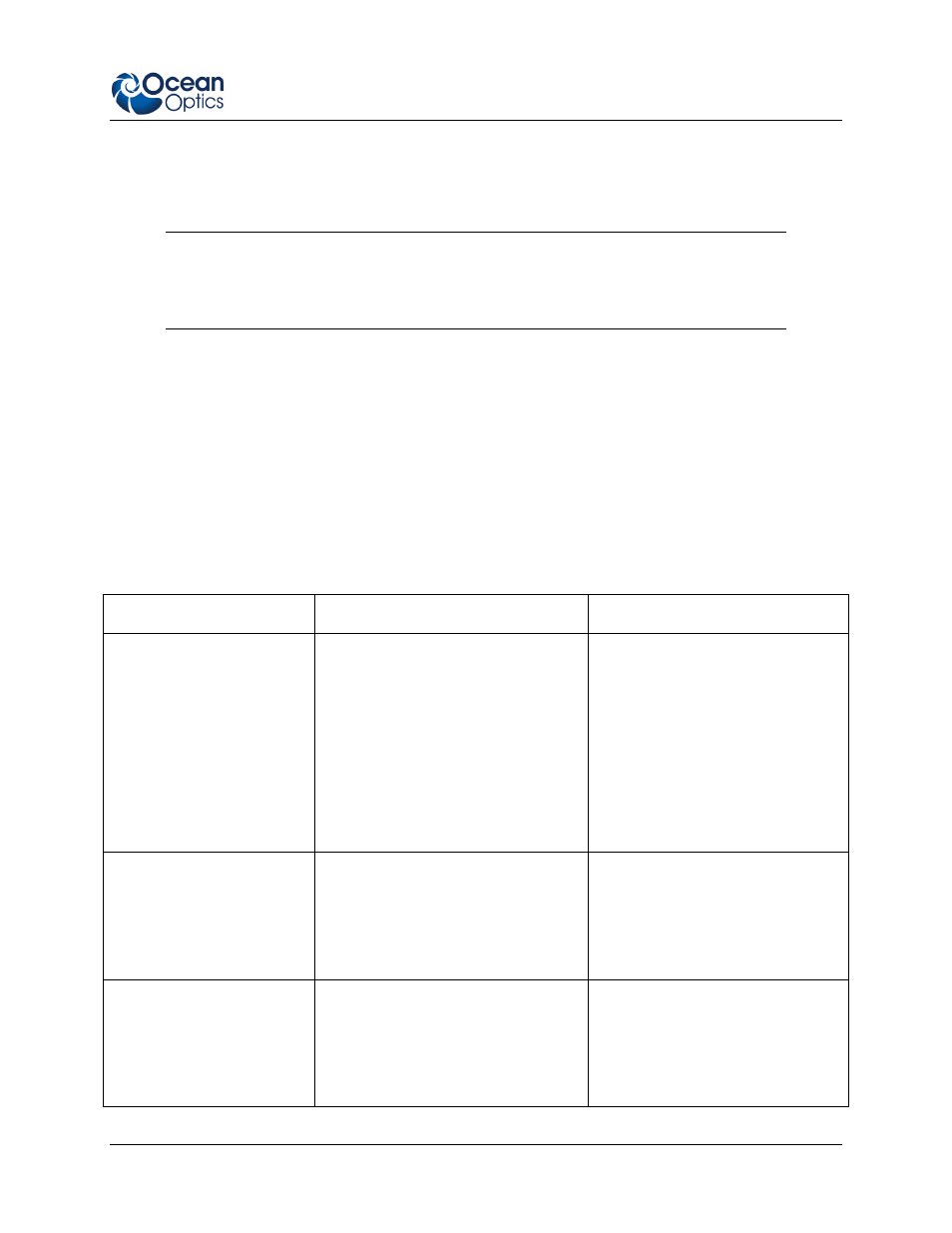

Typical Contamination Effect Possible Cause(s)

Suggested Solution(s)

Transmission in both UV

and visible ranges becomes

low or very unstable.

A contamination layer (such as

biofilm) is sticking to the LWCC wall.

Or, a particle is trapped in the

LWCC.

Flush the cell for 30 seconds each

with each of the 3 cleaning

solvents contained in the

Waveguide Cleaning Kit.

OR

Prepare a 5% surfectant using

Ultrasonic cleaning solution,

followed by HPLC-grade Methanol

and HPLC-grade 2N HCl solution.

Transmission in the UV

range is low. Transmission

in the visible range is OK

and stable.

1. Optic fiber and silica tubing are

coated by a layer of metal

corrosion.

2. Optic fiber and silica tubing are

coated by a layer of organics.

1. Flush with 1 N HCl.

2. Flush with an organic solvent,

such as acetonitrile.

Transmission below 250 nm

is low. Transmission in the

visible range is OK and

stable.

Contamination of fiber optic cable

end-faces with a metal film

generated during repeated

connection attempts.

Wipe all fiber optic endfaces and

fiber connections (on front of the

LWCC) using a fiber optic foam

swab dipped in methyl alcohol.

Use of cotton swabs (Q-Tips) is not

recommended.