10 joint plate assembly, 1 joint plate assembly, top running end carriages – R&M Materials Handling WIRE ROPE PACKAGES User Manual

Page 50

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

50/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

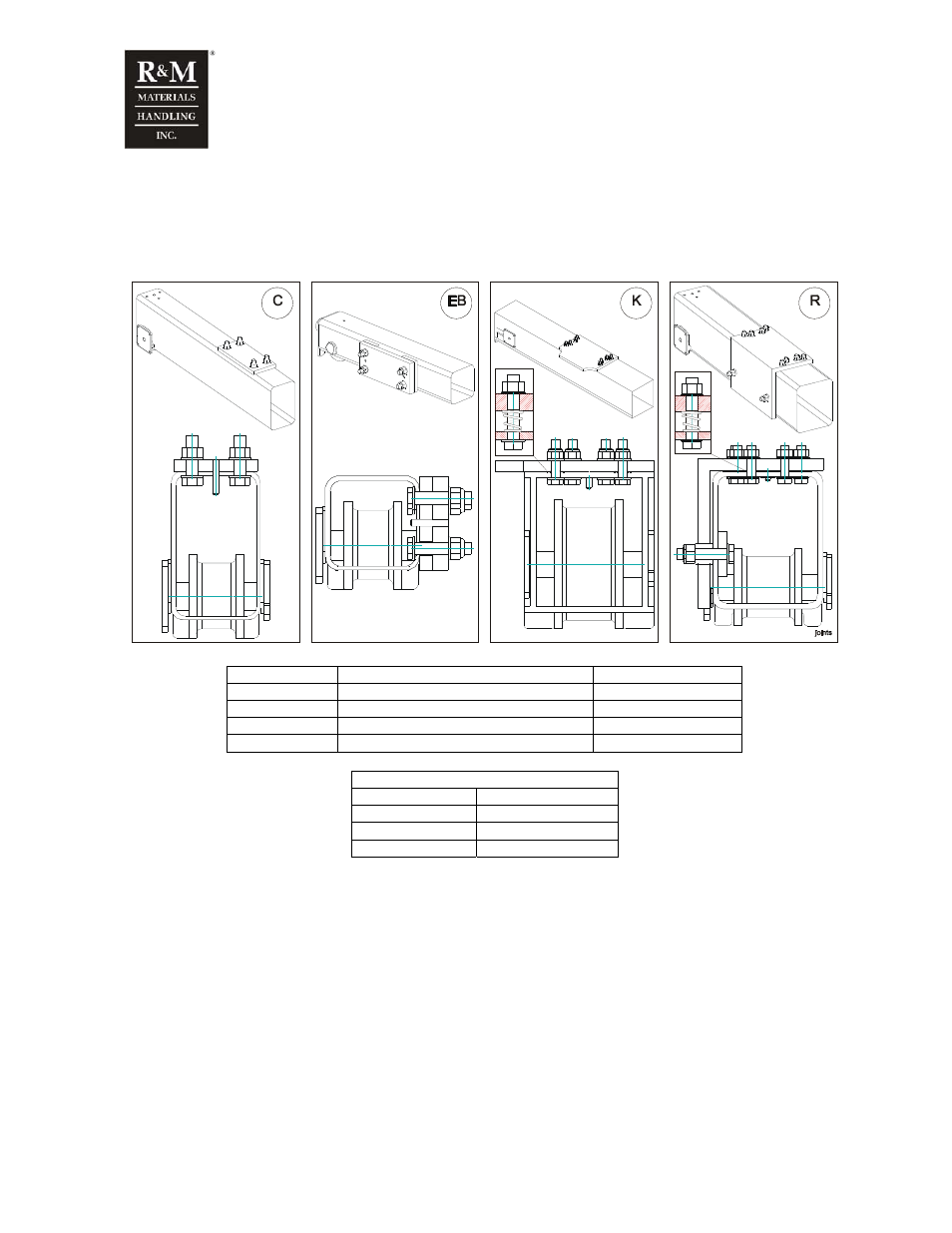

10 Joint plate assembly

10.1 Joint plate assembly, top running end carriages

Pos. Connection

Friction

rings

EB Side

connection

No

C, C-Gantry

Top connection

No

P, L, K

Top connection

Yes

R, S

Top connection / Side connection

Top yes, side no

Tightening torque

Screw size

Tightening torque

M16-10.9 280

Nm

M20-8.8 385

Nm

M20-10.9 550

Nm

• Check that joint surfaces are free from dirt, dust and loose particles. Only shop primer paint is

allowed.

• Place friction rings around screw holes at top of end carriage.

• Reset spring pins into the holes at joint plates so that pin head penetrates the plate about 10-20

mm below bottom surface.

• Place joint plate above the end carriage. Make sure, that spring pins contact with corresponding

holes at the end carriage top plate. Drive pins trough both plates with a hammer and proper tool.

Make sure, that friction rings are kept in position during assembly.

• Assemble screws and nuts.

• Assemble joint plate into final position and tighten screws with correct torque.

• Retighten screws after test runs at assembly site.