Newport Brass 2567 Skylar User Manual

Page 2

Rough in valve Installation

We recommended Installation of this product by a Professional Plumbing Contractor

Note: Use Teflon tape or equivalent to seal all threaded joints.

Warning: To prevent severe damage to valve body, any solder/braze process must be performed

a min. of 4" from ports.

It is strongly recommended that an access panel(s) is built into the roman bath surround.

Access panels allow for ease of trim installation and future possible repairs.

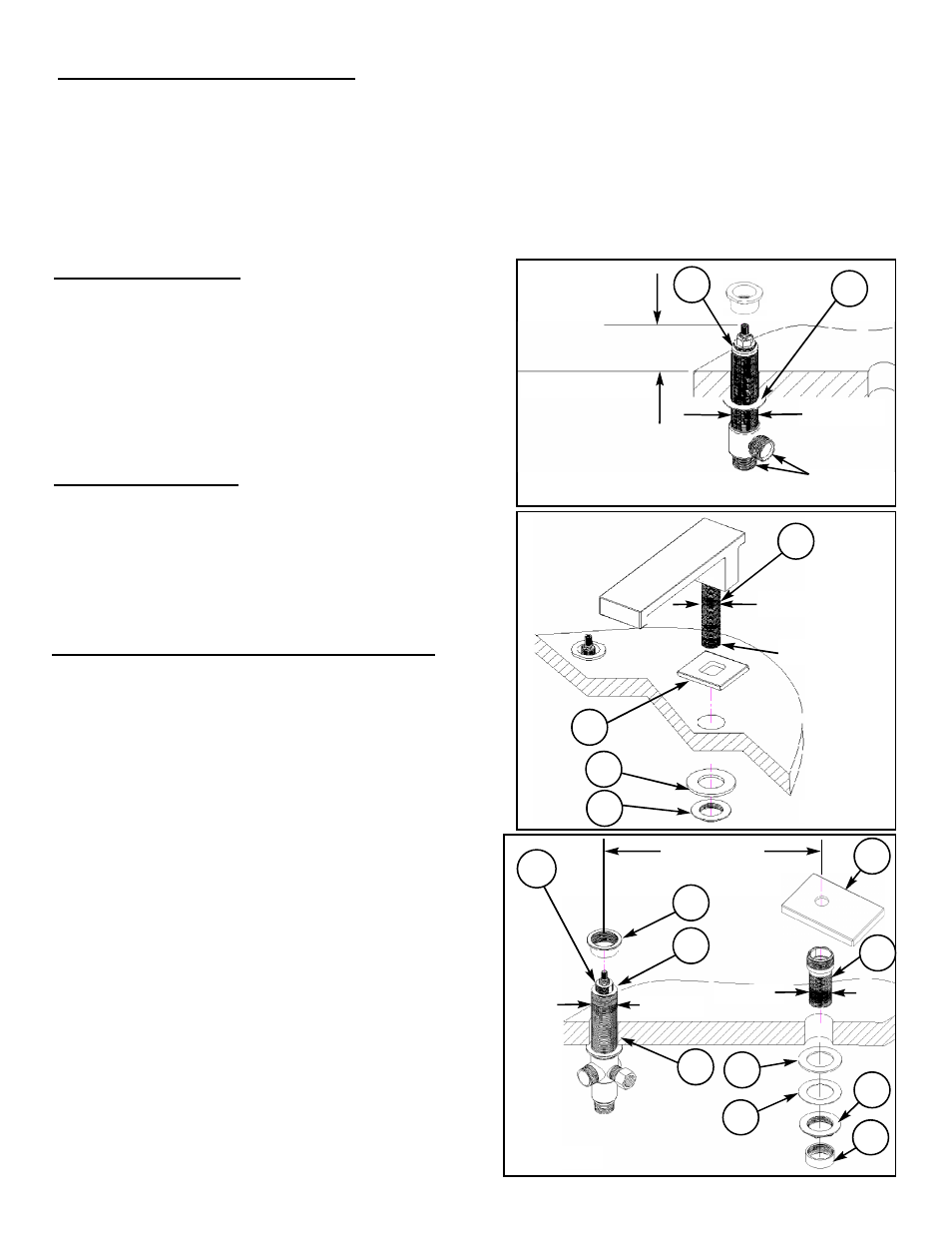

Valve Installation

1. Place flange NUT (1) on valve BODY (2).

2. Insert BODY (2), (blue cold & red hot), through

hole from below mounting surface.

3. Adjust and secure with INVERTED NUT so that the

top of valve stem is 1-5/16” above the mounting

surface. See Figure 1.

Spout Installation

1. Slide spout NIPPLE (3) through center hole of

mounting surface. SPOUT (4) to be flush with deck.

Note: Spacer (80125, not supplied) maybe neces-

sary to clear bath rim.

2. Secure into place with WASHER (6) and MOUNT-

ING NUT (7). See Figure 2.

Figure 1

Finished Deck

Ø1-3/16”

3/4” NPT

1-3/8”

2

1

Diverter and Deck Flange Installation

Note: The maximum distance between mounting

holes is 18”.

1. Thread flange NUT (15) onto diverter VALVE (14).

2. Insert diverter VALVE (14), through hole from

below mounting surface.

3. Adjust and secure with flange CAP (13) so that

the top of diverter stem is 1-5/16” above the

mounting surface. See Figure 3.

4. Thread ADAPTER (14a) onto top of diverter VALVE

(14).

5. Attach deck FLANGE (7) onto NIPPLE (8).

6. Insert NIPPLE (8) through hole in mounting sur-

face.

7. Place rubber WASHER (9), brass WASHER (10)

and flange NUT (11) onto NIPPLE (8) and tighten.

8. Attach plastic SLEEVE (12) onto end of NIPPLE(8).

Figure 3

11

12

13

14

15

18” MAX

9

10

Ш1-3/16”

Ш1-1/2”

14a

NWP-1-657

EN-2108

REV -

Figure 2

Ø1-1/16”

4

5

6

7

3/4” NPT

8

7