Newport Brass 3-1771 Victoria User Manual

Page 2

NWP-1-532T

REV A

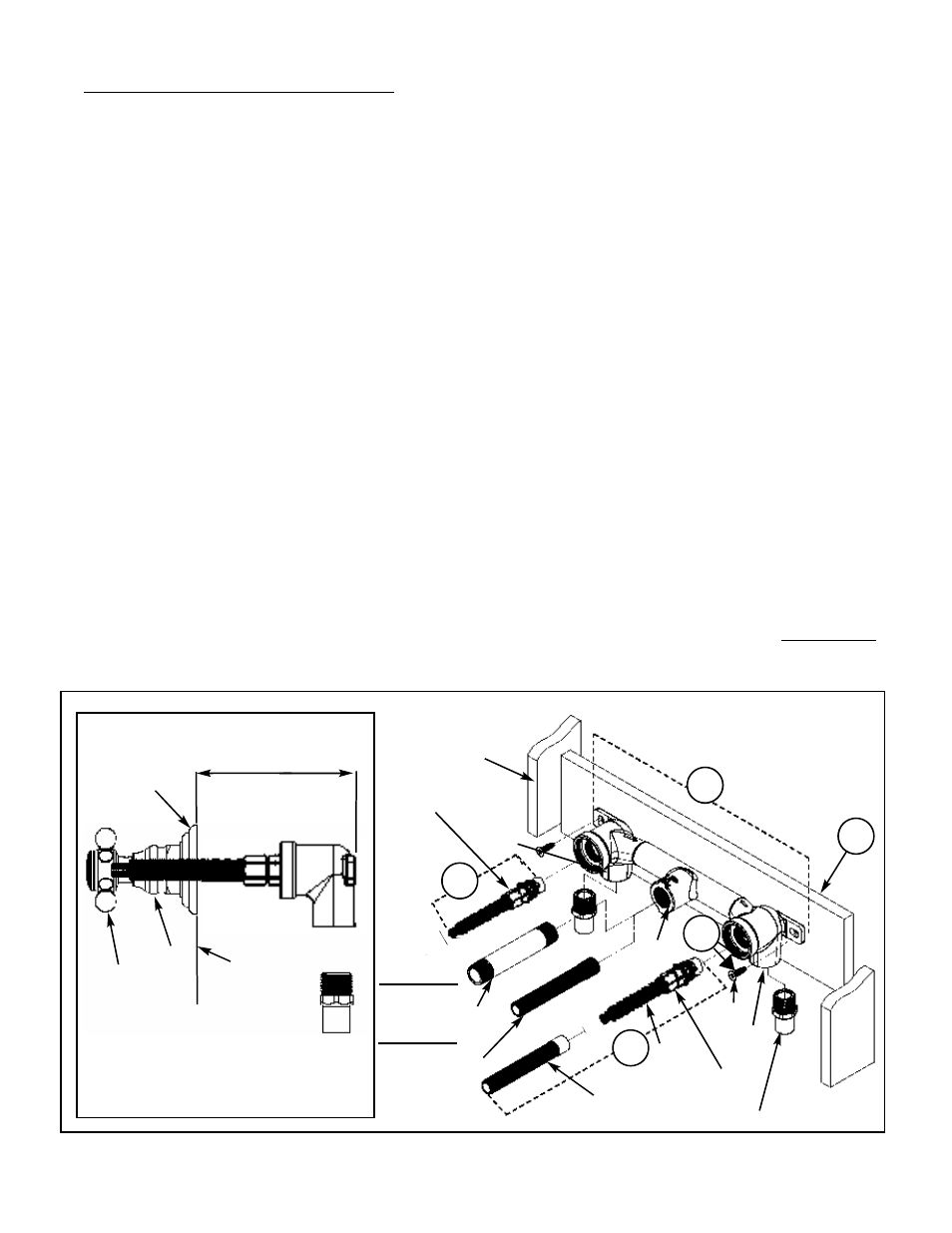

6b.

3/8 NPSM Spout configuration - Instller shall use the appropriate 3/8 NPSM reducer

nipple, (not supplied). Apply thread sealant to 1/2" NPT end of reducer nipple and install onto

valve BODY (1). Rough fit spout (and base ring if supplied) to reducer nipple. Tighten to

desired rotational position. Measure the excess nipple length between spout base/ring and fin-

ished wall. Remove spout and trim excess nipple length.

Trimmed end of nipple to be flat and free of sharp edges and burrs. Apply thread sealant to

trimmed nipple and re-instll spout trim.

7. Install handle escutcheon/bonnet trim and mark the cartridge all-thread nipple where

excess needs to be trimmed.

8. Remove handle escutcheon/bonnet trim and cut cartridge all-thread nipple 1/16" less than

indicated mark to prevent exposure of nipple threads.

9. Cut cartridge stem at least 1/2" to 1 5/8" past the end of the cut all-thread nipple. Final

stem length may vary based on indivitual handle base configuration.(Stem is grooved at 1/2"

intervals.)

10. Install escutcheon/bonnet trim and handle.

11. Secure handle into place by tightening handle setscrew. Note:To achieve desired handle

rotational allignment, the cartridge MUST be tightened in clockwise rotation only. DO NOT

loosen the cartridge. Factory torque of 14 ft-lbs, minimum must be maintained.

Finished Wall Dimension

Handle

Bonnet

Finished Wall

3” MIN

4” MAX

Escutcheon

Vertical

Stud Face

Cartridge Bonnet

5/8” Hex

5

1

4

3

All Thread

STEM

1/2”COPPER SWEAT (5/8” DIA)

Cold

Inlet

1/2” NPT

Hot

Inlet

Outlet Nipple 5b

(Not included)

For 3/8 NPSM spout

configurations

Outlet Nipple 5a

(Not included)

For 1/2 NPSM spout

configurations

2

05/02/2013

Torque Nut

EN-2521

Screw