Ab 2 3 – Peerless-AV HLG452-SM-Q10 - Installation User Manual

Page 6

ISSUED: 08-25-09 SHEET #: 090-9189-6 07-31-12

Visit the Peerless Web Site at www.peerlessmounts.com

For customer care call 1-800-729-0307 or 708-865-8870.

6 of 7

DRIED 3M

RUBBER AND

VINYL #80 SPRAY

ADhESIVE

CLEAN WITh

RUBBINg

ALCOhOL

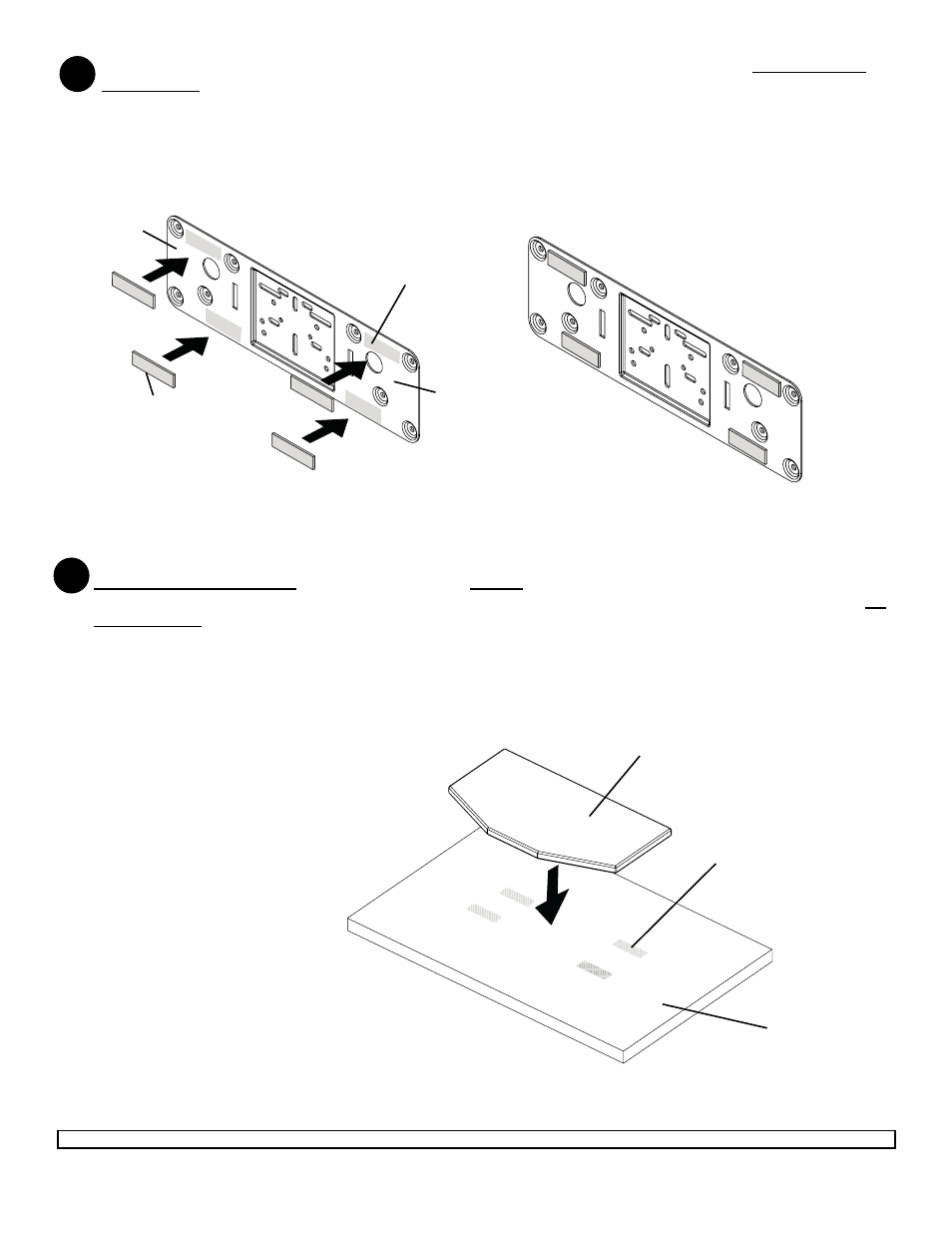

Clean bottom of lock-down plate (

A) with rubbing alcohol. Spray bottom of lock-down plate (A) only where tape

will be applied, with 3M rubber and vinyl #80 spray adhesive (not supplied). Pull apart the four adhesive strips

(

B) and remove red backing from one side. Wait at least 4 minutes for adhesive spray to dry before applying

adhesive strip (

B). Attach adhesive strips (B) firmly to bottom of lock-down plate (A) as shown below.

A

B

2

3

Clean desk surface with rubbing alcohol. Use 3M rubber and vinyl #80 spray adhesive (not supplied) on the

mounting surface area only. Note: Spray adhesive will not remove easily. Wait at least 4 minutes to dry before

removing tape backing from lock-down plate (

A) and placing firmly on surface. Note: There is a recommended 72

hour cure time for tape on lock-down plate (A).

Note: Once tape backing is removed be careful not to touch the sticky surface of the tape with fingers, as this can

cause the tape to lose some of its holding power.

Note: After application of tape on lock-down plate (A), the bond strength will increase as the adhesive flows onto

the surface.

DISPLAY BASE STAND

DRIED 3M RUBBER

AND VINYL #80 SPRAY

ADhESIVE (not supplied)

DESk SURFACE

Note: Display base stand may appear

different than illustrated.

At room temperature, approximately 50%

of the ultimate strength will be achieved

after 20 minutes, 90% after 24 hours, and

100% after 72 hours. In some cases, bond

strength can be achieved more quickly by

exposure to elevated temperatures (e.g.

150°F [66°C] for 1 hour).